A pipeline exhaust detection method

A detection method and pipeline technology, applied in the detection/exploration of underground/near-surface gas, measurement devices, geophysical measurement, etc., can solve problems such as easy blockage, affecting product qualification rate, and large number of internal pipelines, and achieve reduction Loss, the effect of improving the pass rate of product inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below.

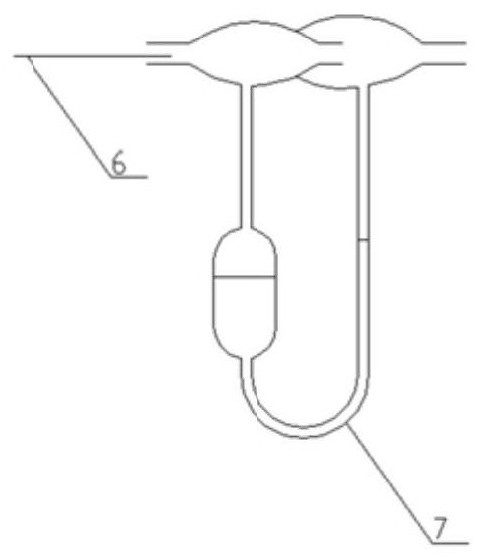

[0019] The pipeline exhaust detection method of the present invention is provided with a detection channel connected to the channel to be tested, the channel to be tested and the detection channel are both connected to the air inlet, the remaining exhaust ports are excluded, and a flow meter is connected to the detection channel. If the gas flow rate is measured by the flowmeter, the exhaust of the channel to be tested is not smooth; otherwise, the exhaust of the channel to be tested is smooth.

[0020] After a certain channel to be tested is detected, seal the channel outlet, open the exhaust port of the other channel to be tested, connect the flowmeter, and seal the remaining exhaust ports, and still use whether the flowmeter can detect the gas flow rate to determine Judge the smoothness of the exhaust of the channel to be tested.

[0021] When there is only one exhaust port of the channel to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com