Drilling and hole-flushing integrated device for coal mine gas extraction

A coal mine gas and hole washing technology, which is applied in the direction of gas discharge, safety devices, drill bits, etc., can solve the problems that it is difficult to clean soft rock or slag, affect the efficiency of gas extraction, and the efficiency of hole washing and drilling is low. Achieve fast drilling and washing operations, protect the drill bit, and improve the drilling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

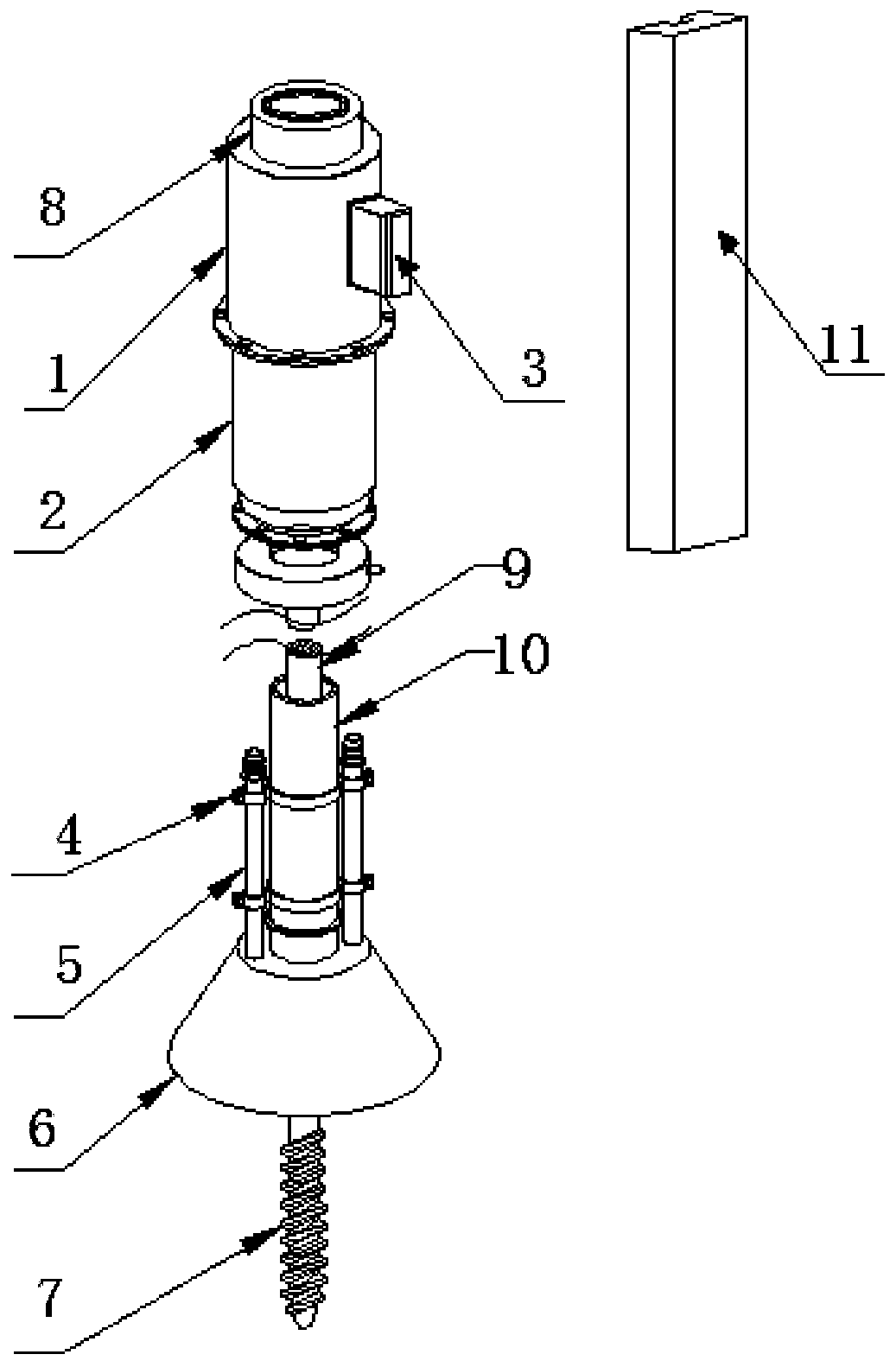

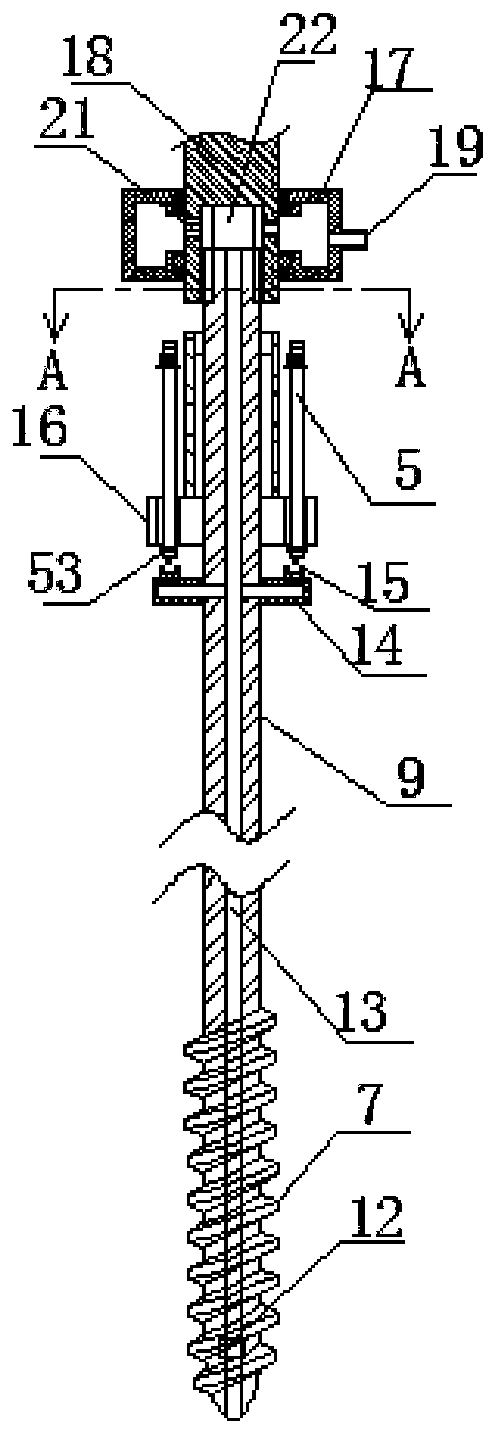

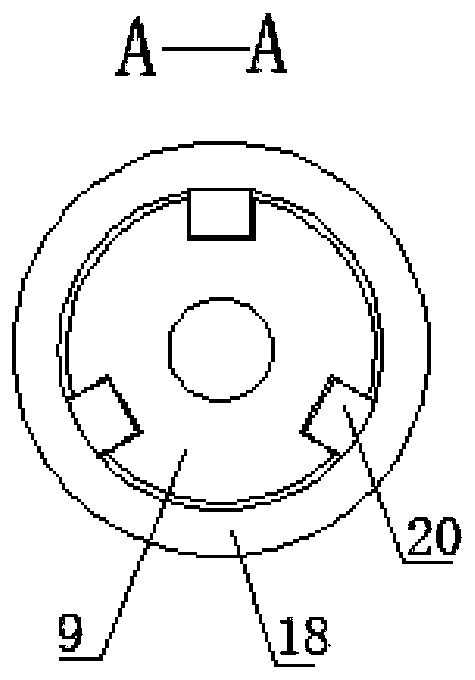

[0032] see Figure 1-8 , in an embodiment of the present invention, a coal mine gas extraction adopts an integrated device for drilling and washing holes, including a drilling and washing traveling track 11, a drilling motor 1, a drill rod 9 and a drill bit 7, wherein the drilling motor 1 A traveling slider 3 is fixedly connected to the top, and the traveling slider is moved along the drilling and washing hole traveling track 11, and the output end of the drilling motor is connected to the drilling rod 9, and the front end of the drilling rod is the same as The shaft is fixedly connected with the drill bit 7; it is characterized in that a sleeve 10 is set on the outside of the drill rod close to the position of the drilling motor, and at least one high-pressure hole washing pipe 5 is arranged on the sleeve. A high-pressure joint seat 14 is also arranged on the drill pipe corresponding to the position of the high-pressure hole-washing pipe; the high-pressure hole-washing pipe c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com