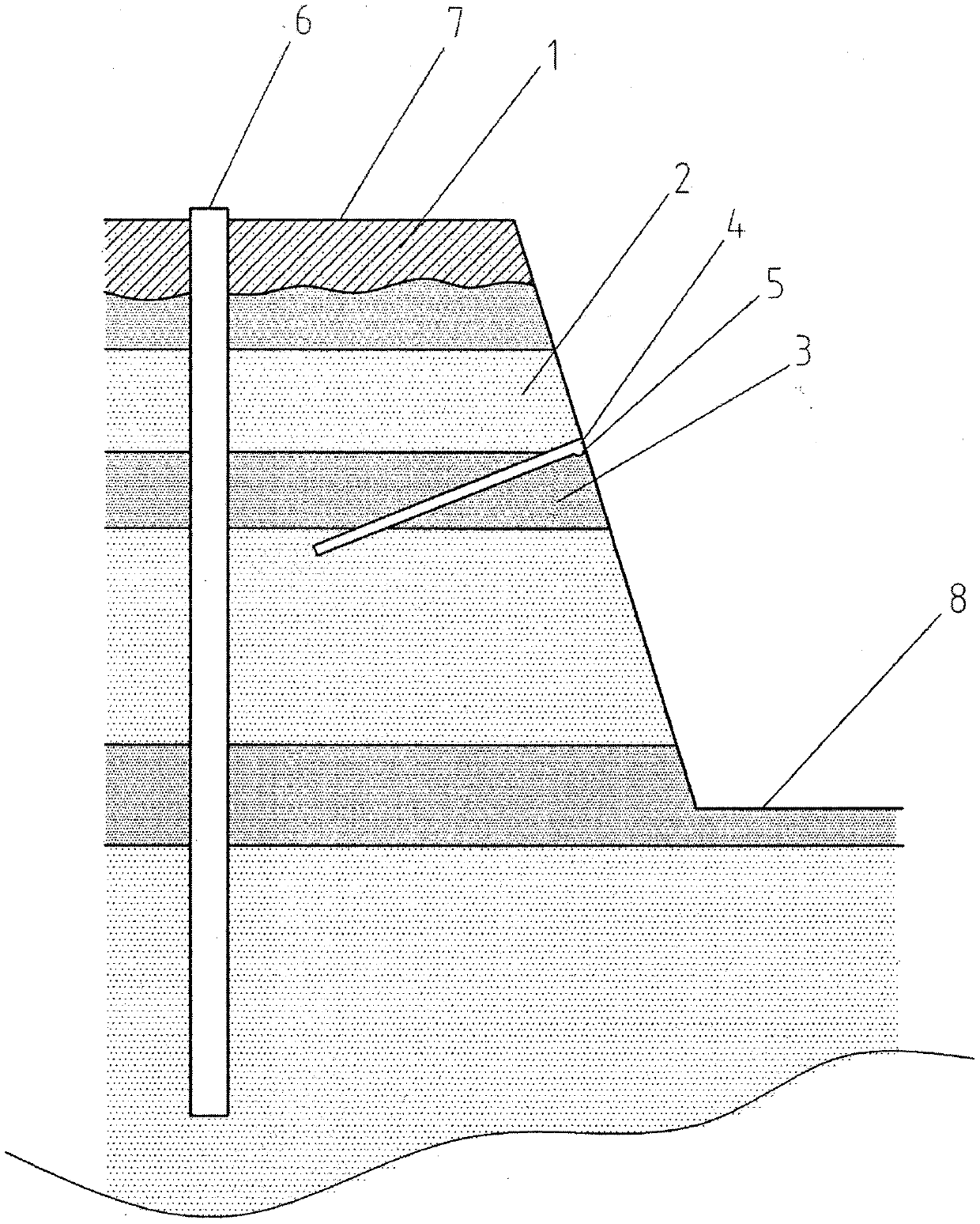

Construction method for treating flowing sand of deep foundation pit slope

A technology for deep foundation pits and quicksand, which is applied in infrastructure engineering, excavation, construction, etc., can solve problems such as excessive labor and power consumption, inconvenient underground engineering construction operations, and consumption affecting excavation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The implementation process mainly includes 4 stages: formulation of the plan, material preparation, implementation of operations and post-management.

[0040] 1. Formulate a plan First of all, we must first find out the basics, and evaluate and judge according to the site situation, surrounding environment and other factors.

[0041] 1.1 Do a good job in relevant investigations for the purpose of preventing quicksand on the slope. First, consult the geological survey report of the project to determine whether there is a possibility of geological characteristics of quicksand on the slope and whether there is stagnant water. If the surface water system environment is rich within at least 200m around the foundation pit and the geological survey report has been reported for many years, if necessary, at least one water level observation well should be drilled at suspicious points around the foundation pit to confirm the current groundwater level.

[0042] 1.2 If the geologica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com