Cocoon sorting machine

A cocoon selection and automatic technology, applied in the field of silk reeling, can solve the problems of low test accuracy, waste, and complicated methods, and achieve the effect of improving the efficiency of cocoon selection and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

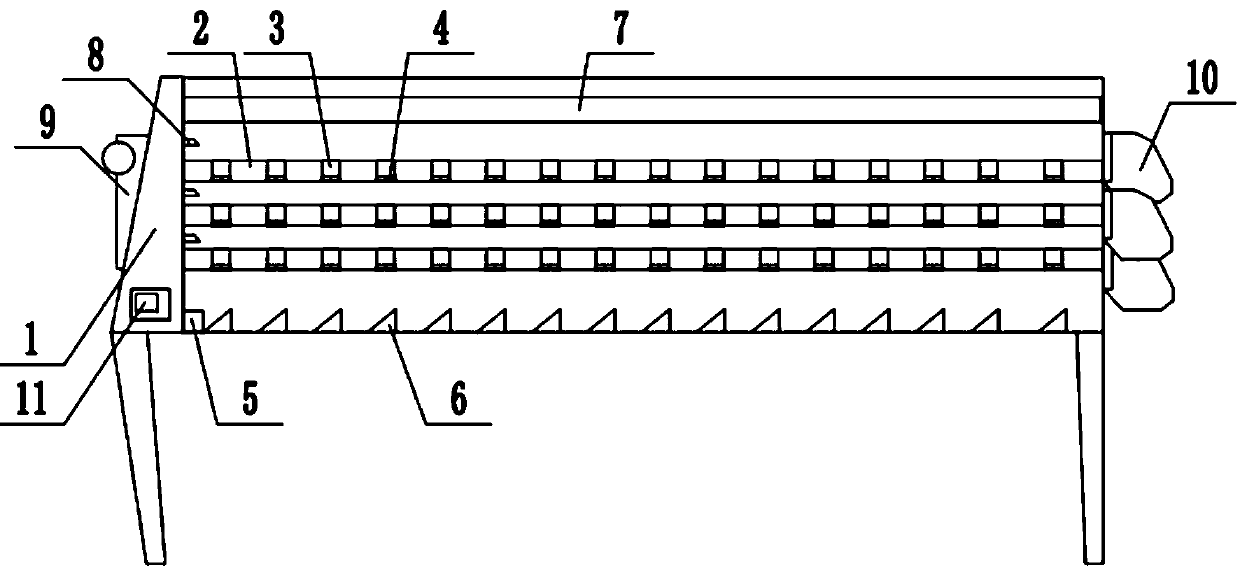

[0018] An automatic cocoon sorting machine, comprising: a frame 1, a cocoon sorting table 2, a cocoon sorting slot 3, a cocoon sorting slot baffle 4, a near-infrared light source 5, a beam splitter 6, a receiver 7, a high-pressure air nozzle 8, Air compressor 9, collection bag 10 and controller 11, three layers of cocoon selection platforms 2 are installed in the frame 1, a number of cocoon selection slots 3 are evenly distributed on each cocoon selection platform 2, each cocoon selection slot 3 The cocoon selection tank baffle plate 4 with electric opening and closing is installed at the bottom, and the collection bag 10 is installed at the end of each cocoon selection platform 2. A beam splitter 6 is installed corresponding to the cocoon selection slot 3, a receiver 7 is installed at the position corresponding to the cocoon selection slot 3 on the top of the frame 1, and a high-pressure air nozzle 8 is installed on one side of the cocoon selection platform 2 of each layer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com