Blast furnace hot air branch pipe end hole refractory repairing method

A technology of hot blast branch pipes and repair methods, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as rising molten iron costs, affecting blast furnace combustion consumption, and deterioration of furnace conditions, so as to reduce production costs and promote rapid production recovery. The effect of meeting production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described.

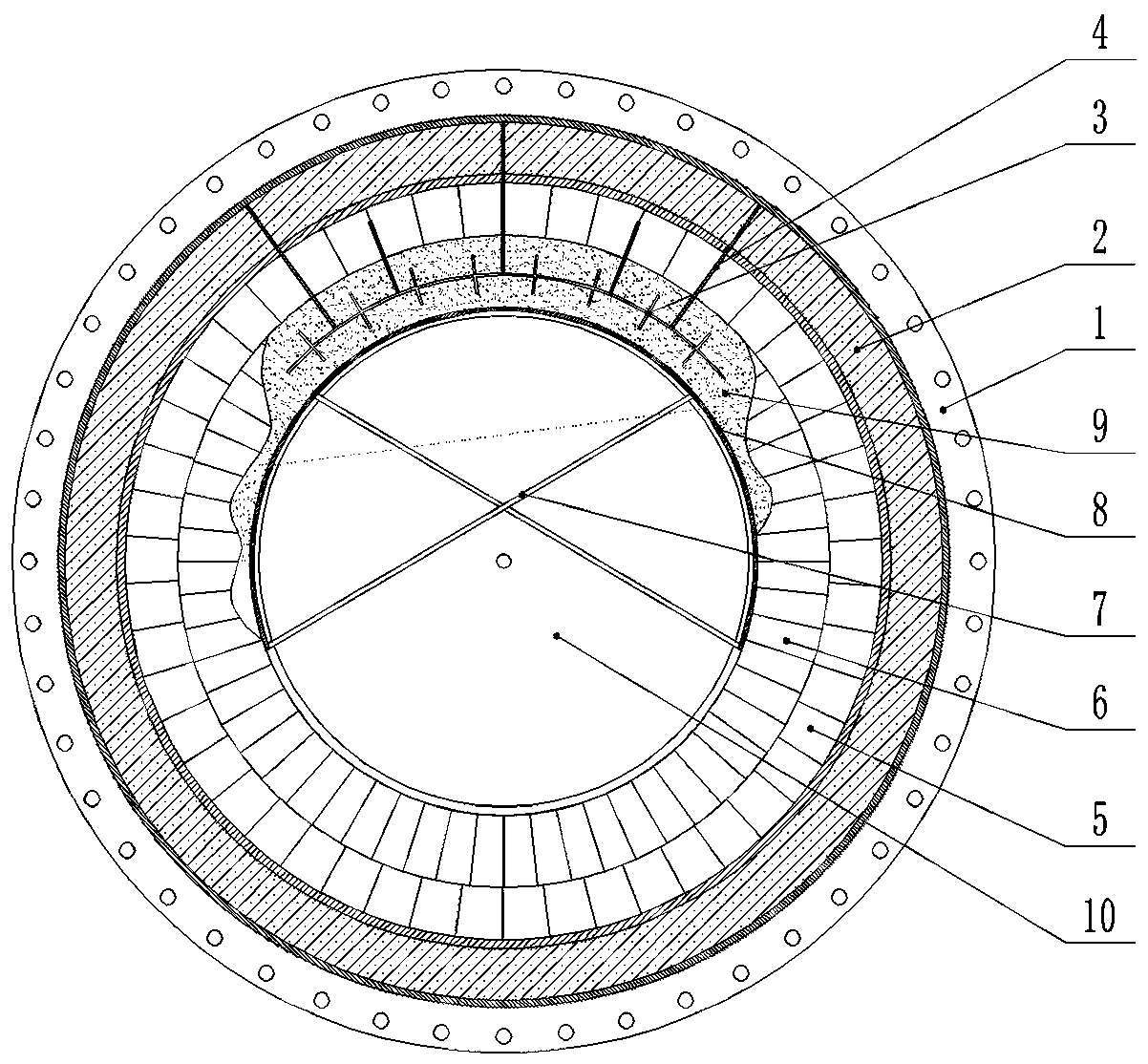

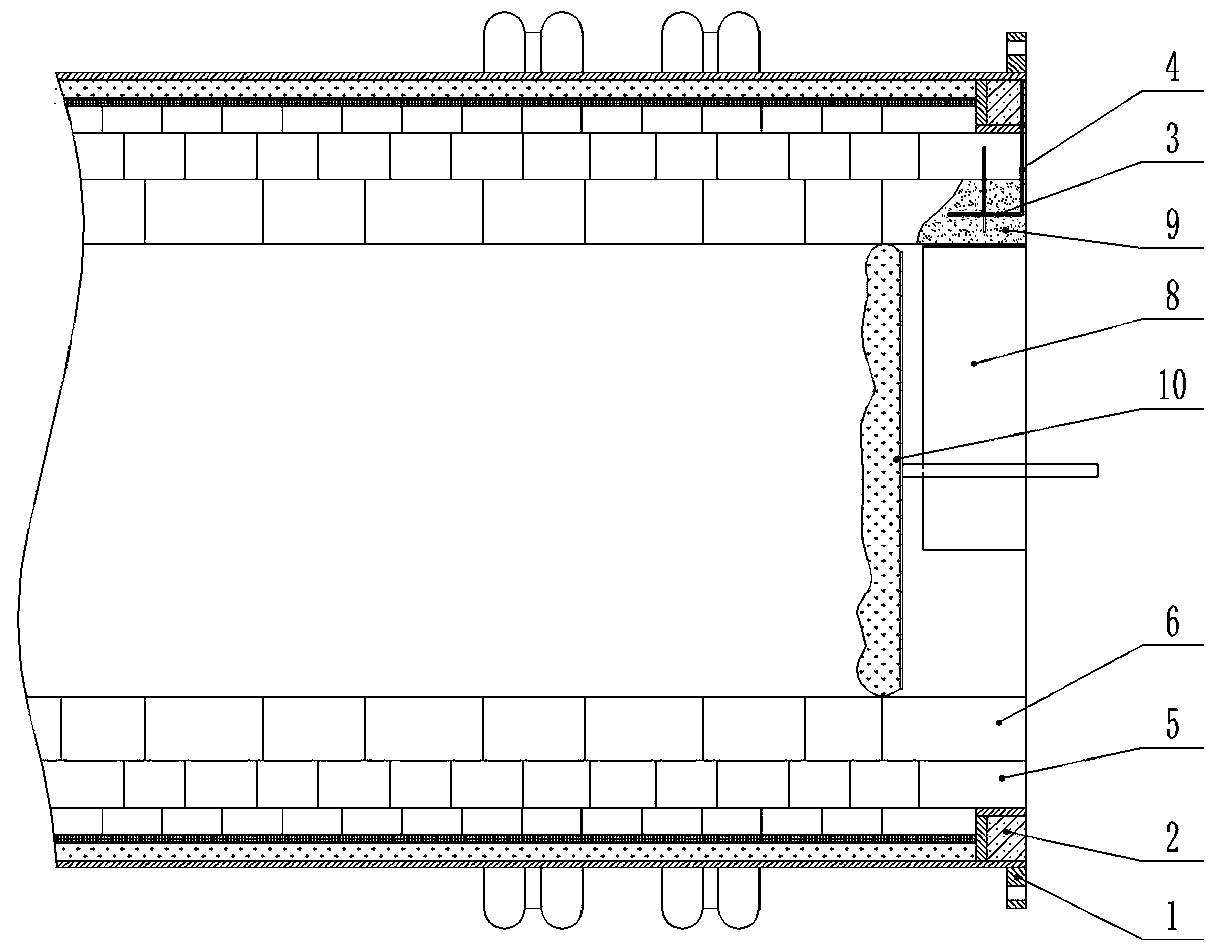

[0015] see figure 1 with figure 2 , a method for repairing refractory materials at the ports of blast furnace hot blast branch pipes, the repair steps are:

[0016] The first step is to thoroughly clean the damaged part of the refractory material at the port of the hot air branch pipe, including cracks or cracks. After cleaning, blow it with compressed air;

[0017] In the second step, the pouring steel mold 8 is made according to the diameter of the inner wall of the hot air duct, and fixed by the pouring steel mold 8 fixing bracket 7; the steel plate of the pouring steel mold 8 can be made of a 3mm ordinary steel plate. The fire screen 10 can be made to insulate the inside of the hot air branch pipe and the three-fork of the hot air main pipe;

[0018] The third step is to make the pouring skeleton 3 and fix it. If the refractory spray paint filling layer 2, high alumina refractory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com