A tire mold cutting plotter

A technology for tire molds and cutting plotters, which is applied in the direction of manufacturing tools, metal processing machinery parts, metal processing, etc., can solve the problems of troublesome operation, high labor intensity, heavy tire molds, etc., and achieve the effect of reducing friction and facilitating processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

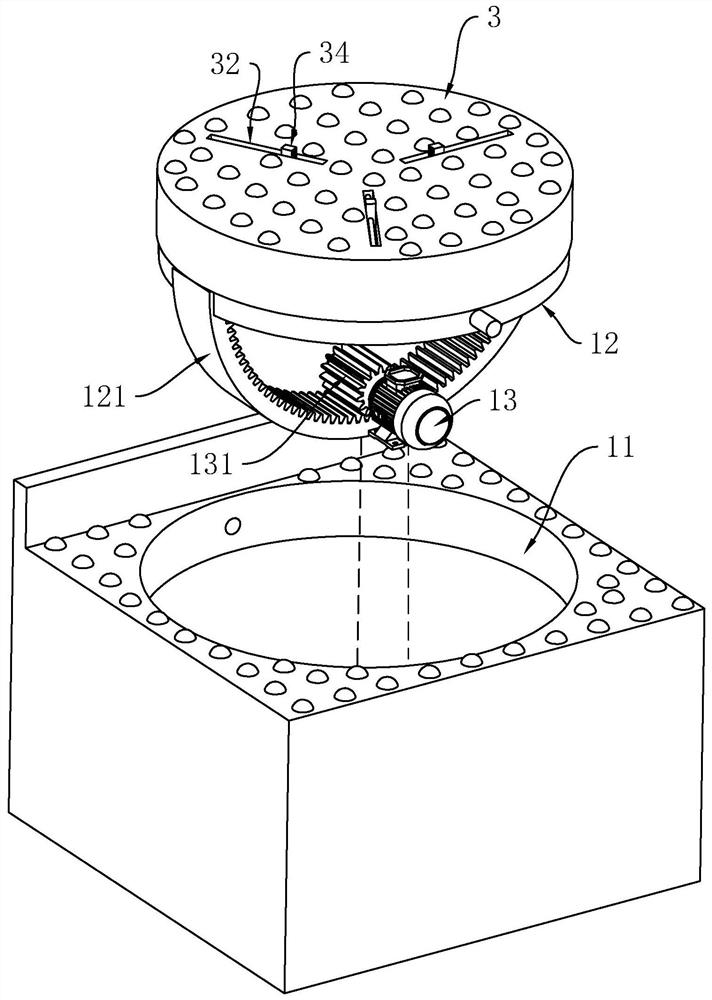

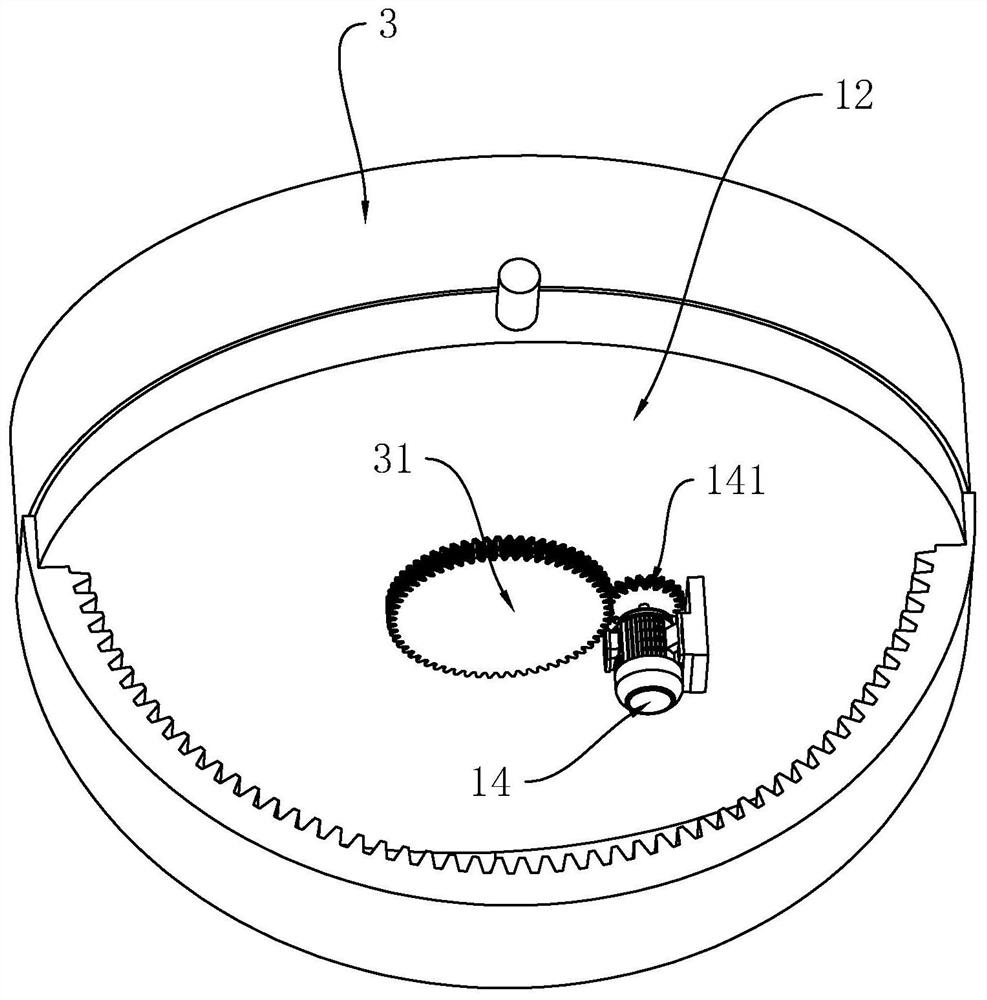

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

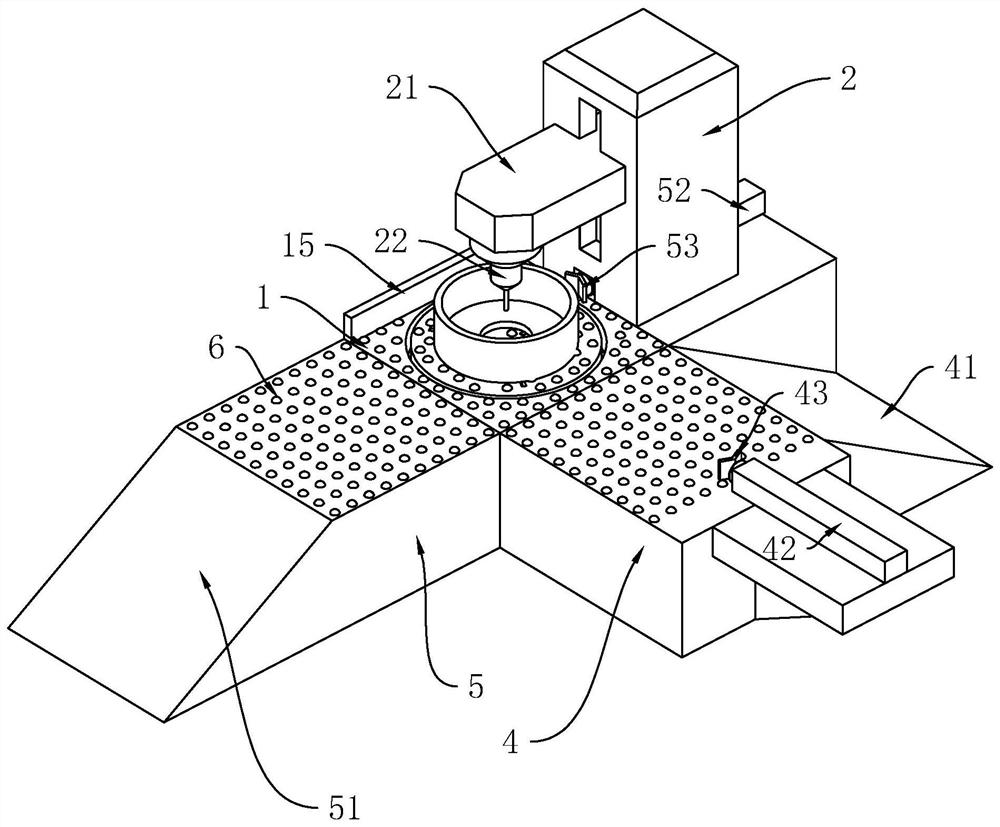

[0038] refer to figure 1 , is a cutting plotter for tire molds disclosed by the present invention, including a base 1, a stand 2 is vertically fixed on one side of the base 1, and a vertically slidably connected side of the stand 2 close to the base 1 is connected with a horizontally arranged Lifting arm 21, a lift cylinder (not shown) that can drive lifting arm 21 to slide vertically is also provided in the stand 2, and the lower side of one end of lifting arm 21 away from the stand 2 is fixedly connected with a lettering head 22 (Here is the existing technology and will not go into details here). During work, the tire mold is placed on the base 1, and the lettering head 22 is driven up and down by the lifting cylinder, the height of the lettering head 22 can be adjusted, and then the tire mold can be processed through the lettering head 22 .

[0039] refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com