Method of riveting heavy and medium metal sheets without projections on double faces

A protruding object and metal plate technology, applied in the field of riveting of medium-thick metal plates, can solve the problems of complex rivet structure, difficult production, cumbersome riveting steps, etc., achieve high-quality riveting, reduce grinding processes, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations of the present invention rather than limitations.

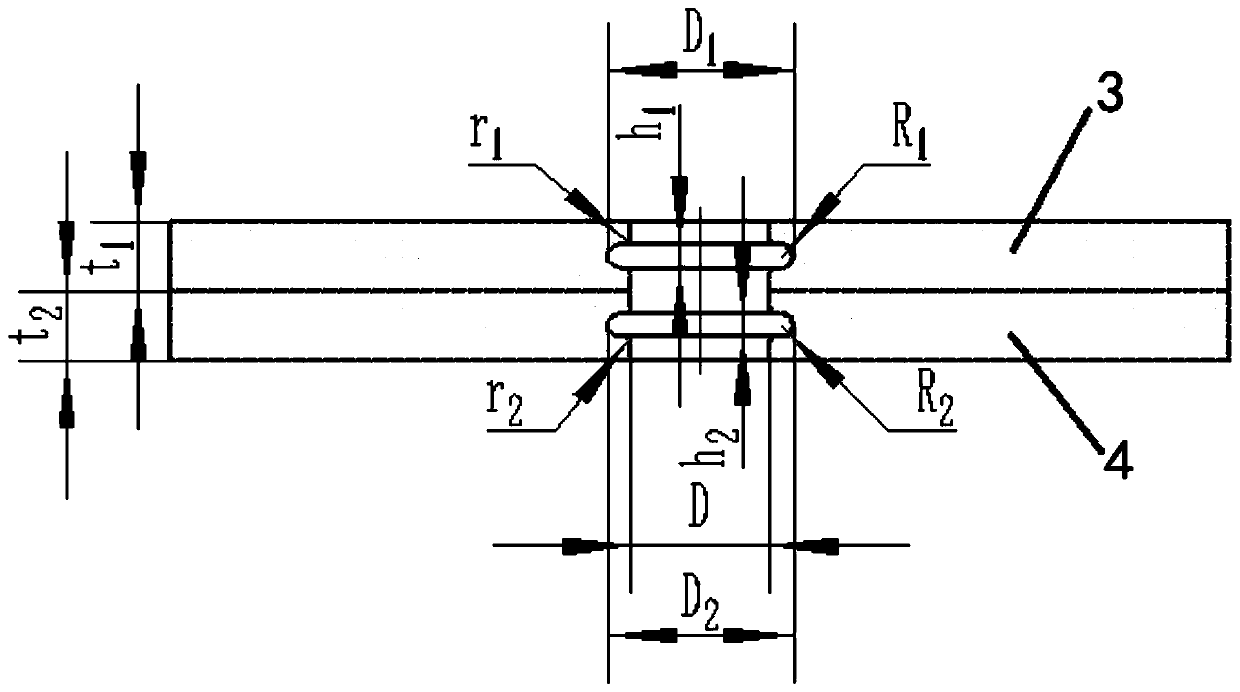

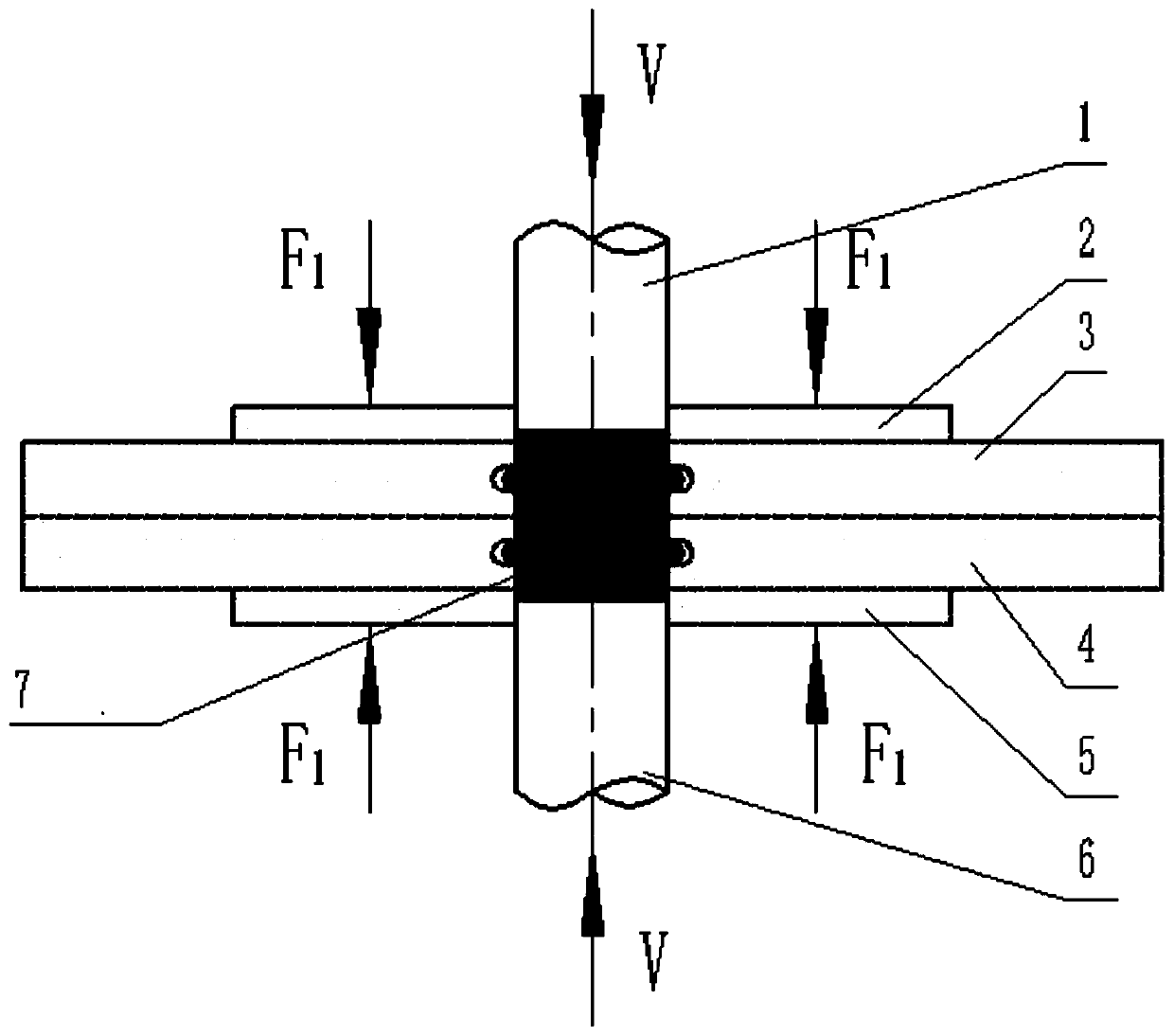

[0041] The method for the riveting of double-sided medium-thick metal plates without protrusions of the present invention firstly pre-treats the upper sheet material 3 and the lower sheet material 4 to be riveted, such as figure 1 , at wall thickness t 1 A round hole with a diameter of D is processed on the upper plate 3 to be riveted, and several holes with a diameter of D are processed on the inner wall of the round hole. 1 , the height is h 1 The annular groove; at wall thickness t 2 A round hole with a diameter of D is processed on the lower plate 4 to be riveted, and several holes with a diameter of D are processed on the inner wall of the round hole. 2 , the height is h 2When the number of annular grooves in the upper circular hole of the upper plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com