Detachable riveting gun barrel

A gun shaft and rivet technology, applied in the field of rivet guns, can solve the problems of increasing the strength of riveting, difficult riveting of rivet guns, short length of gun shaft, etc., and achieves the effects of uniform force, effective transmission, and reasonable length setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

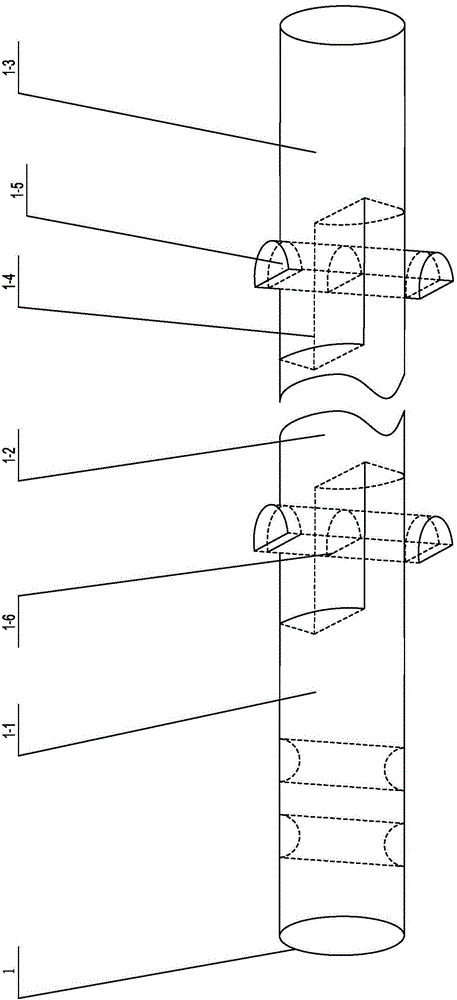

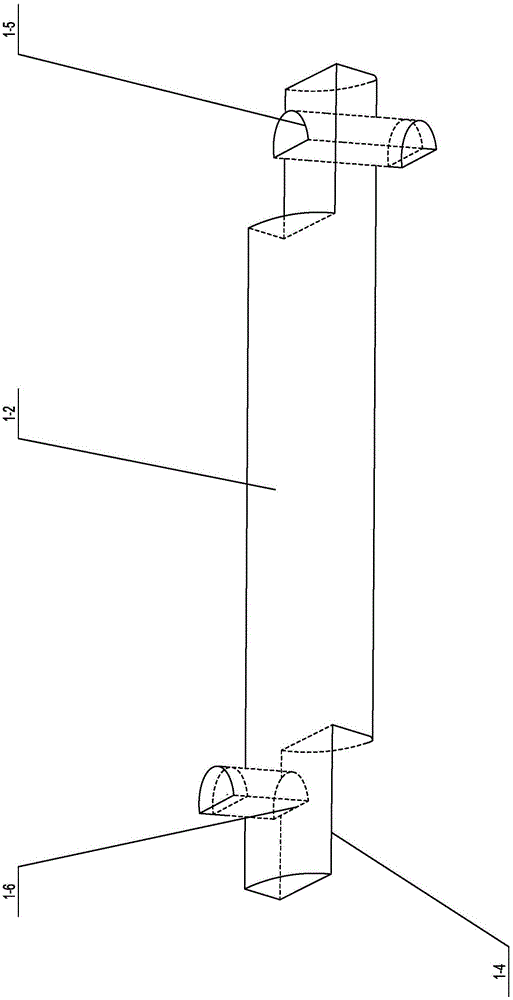

[0021] Such as figure 1 A specific embodiment of the present invention is proposed as shown, a detachable rivet gun shaft, including a gun shaft body 1, and the gun shaft body 1 includes a gun shaft head section 1-1, several gun shaft middle sections 1-2, and gun shaft end sections 1-3 , the length of the gun barrel body 1 is realized by adjusting the number of middle sections 1-2 of the gun barrel according to the application occasion, the size of the applied force, and the limitation of space. If the space is narrow and the required force is not large, the gun barrel body 1 is selected from the first section of the gun barrel 1-1 and the bottom section 1-3 of the gun barrel can be connected. If the required force is large and the space is sufficient, an appropriate number of middle sections 1-2 of the gun barrel can be selected for connection.

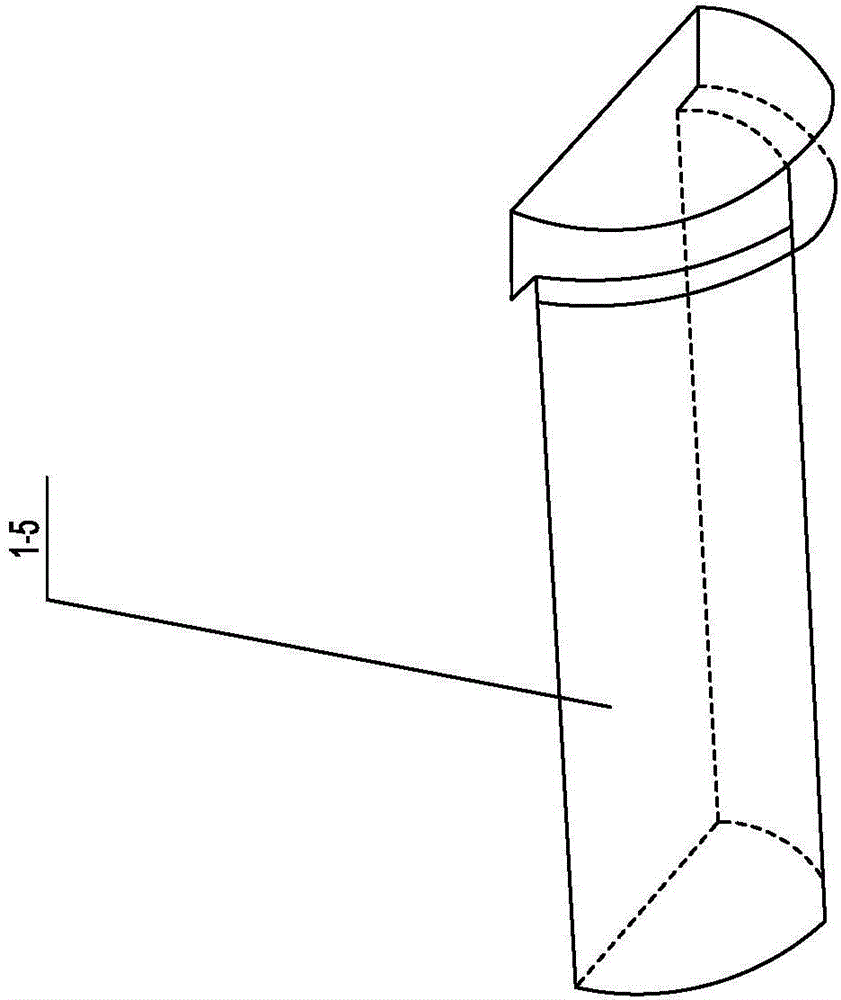

[0022] The left side or the right side of the connecting ends of the two adjacent joints are provided with two connecting blocks 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com