Steel pipe surface spraying equipment

A surface spraying and equipment technology, applied in the field of steel pipe surface spraying equipment, can solve the problems of reducing work efficiency and inconvenient operation, and achieve the effect of improving work efficiency and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

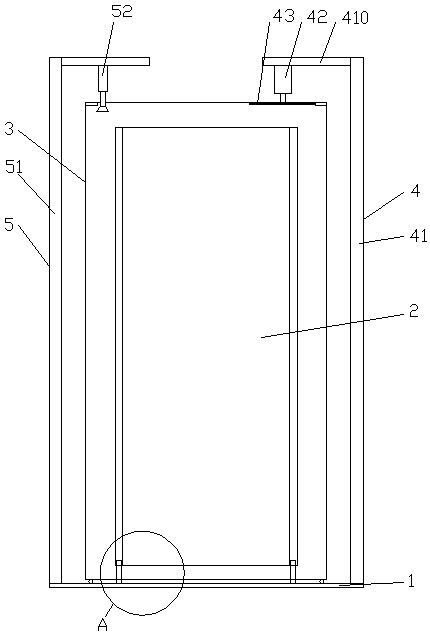

[0028] The present invention as Figure 1-3 As shown, it includes a base 1, an external support mechanism 3, a driving mechanism 4 and a spraying mechanism 5,

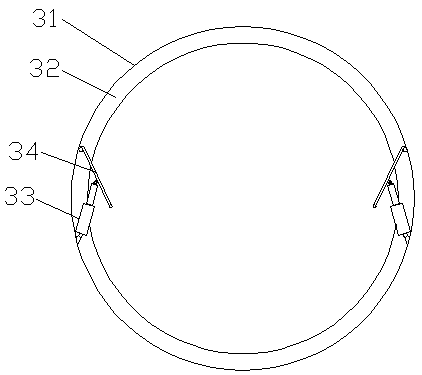

[0029] The outer support mechanism includes an outer cylinder 31, the outer cylinder is rotatably connected to the base, the inner wall of the upper mouth of the outer cylinder is provided with an inner ring rack 32, and the inner wall of the outer cylinder is provided with a pair of symmetrically arranged External scraper components,

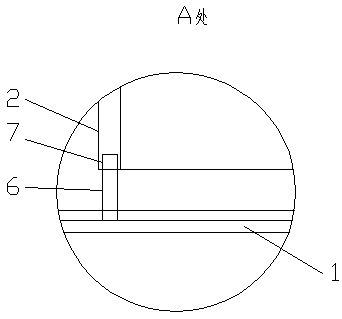

[0030] A pipe body 2 is arranged inside the outer cylinder, and the pipe body is rotatably connected to the base,

[0031] Described driving mechanism comprises L-shaped upright bar one 41, motor 42 and gear 43, and described L-shaped upright bar one is arranged on the base, and is positioned at the outside of urceolus, and described motor drives gear, and described motor is connected on L On the crossbar 410 of the L-shaped vertical rod one, the crossbar of the L-shaped vertical rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com