A fish-scale-like microchannel and multi-layer cold plate mounting frame based on 3D printing technology

A technology of microchannel and mounting frame, which is applied in the field of design and installation of bionic three-dimensional microchannel radiators, can solve the problems of limited heat dissipation capacity, simple installation structure, and inability to realize mass production, etc., to achieve enhanced pressure, uniform distribution of speed and temperature, Even force distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

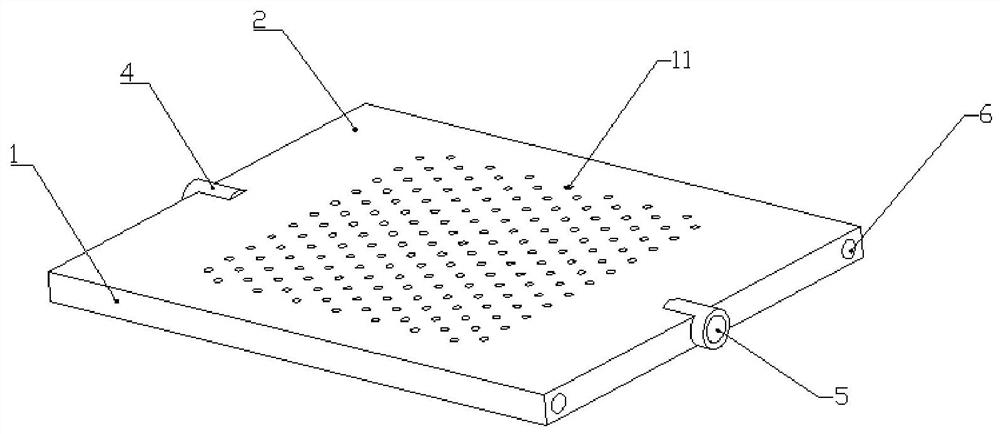

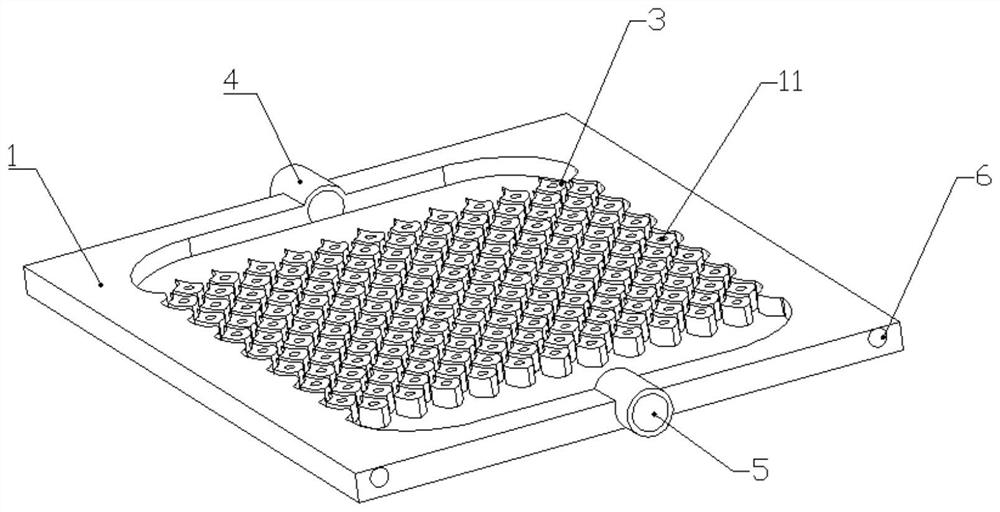

[0037] A three-dimensional fish-scale-like microchannel cold plate based on metal 3D printing technology. The phased array T / R components are distributed on the surface of the cover plate of the micro-channel radiator. The heat dissipation channel composed of 3, the water inlet 4 and the water outlet 5 are opened in the middle of the two sides of the radiator, the coolant enters from the water inlet 4, evenly passes through the arrayed fish scale-shaped protrusions 3 heat dissipation channels, and finally flows from the water outlet 5 out, complete a round of convection cooling in the radiator.

Embodiment 2

[0039] On the basis of Example 1, the microchannel cold plate 1 is installed on the mounting frame in turn, and for the heat dissipation of the heat source of the phased array T / R component, the heat source is installed on the cover of each layer of radiator through each through hole and wiring hole On the surface of board 2, coolant can be injected from the multi-interface blind plug water connector (water inlet) 7(a) of the mounting frame, each multi-interface blind plug water connector (water inlet) 7(a) and the multi-interface blind plug water connector The port of (water outlet) 7(b) corresponds to the water inlet 4 and the water outlet 5 of a microchannel cold plate. The cooling liquid enters the cold plate of each layer through the interface to conduct convection heat dissipation with the heat source, and then passes through the multi-interface blind plug water joint ( Outlet water) 7(b) flows out to complete the overall heat dissipation process of a round of laminated c...

Embodiment 3

[0041] The microchannel cold plate is provided with a cavity for cooling liquid to flow through. The cavity is composed of four arcs with a radius of 3mm. The specific design dimensions are shown in Figure 3(b). There are gaps, and the gaps between all block-shaped protrusions form microchannels, which are fish-scale-like in shape, and the specific structure is shown in Figure 3(a).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com