Method for automatically testing ripple noise of power supply

An automatic test and power supply ripple technology, applied in the field of ripple noise, can solve the problems of inaccurate measurement of power supply ripple noise, instability, low efficiency, etc., and achieve the effect of fast and flexible switching position, accuracy and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with specific embodiments.

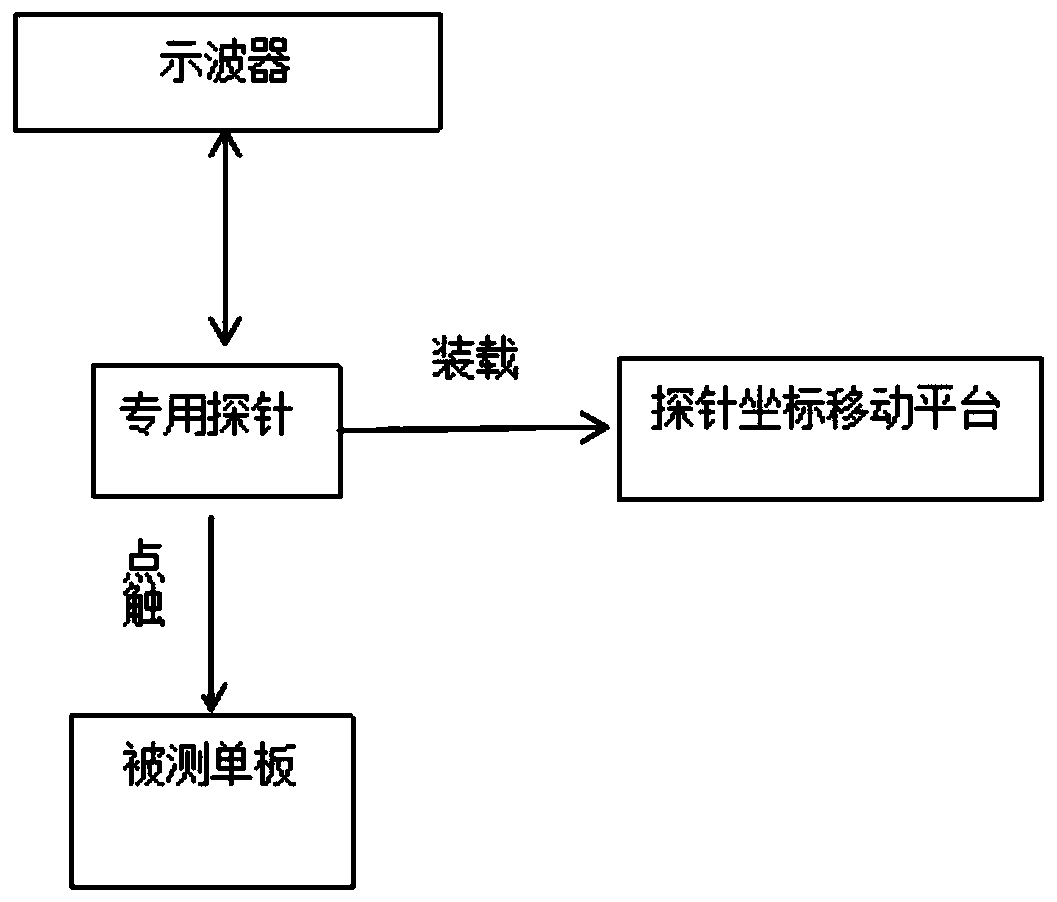

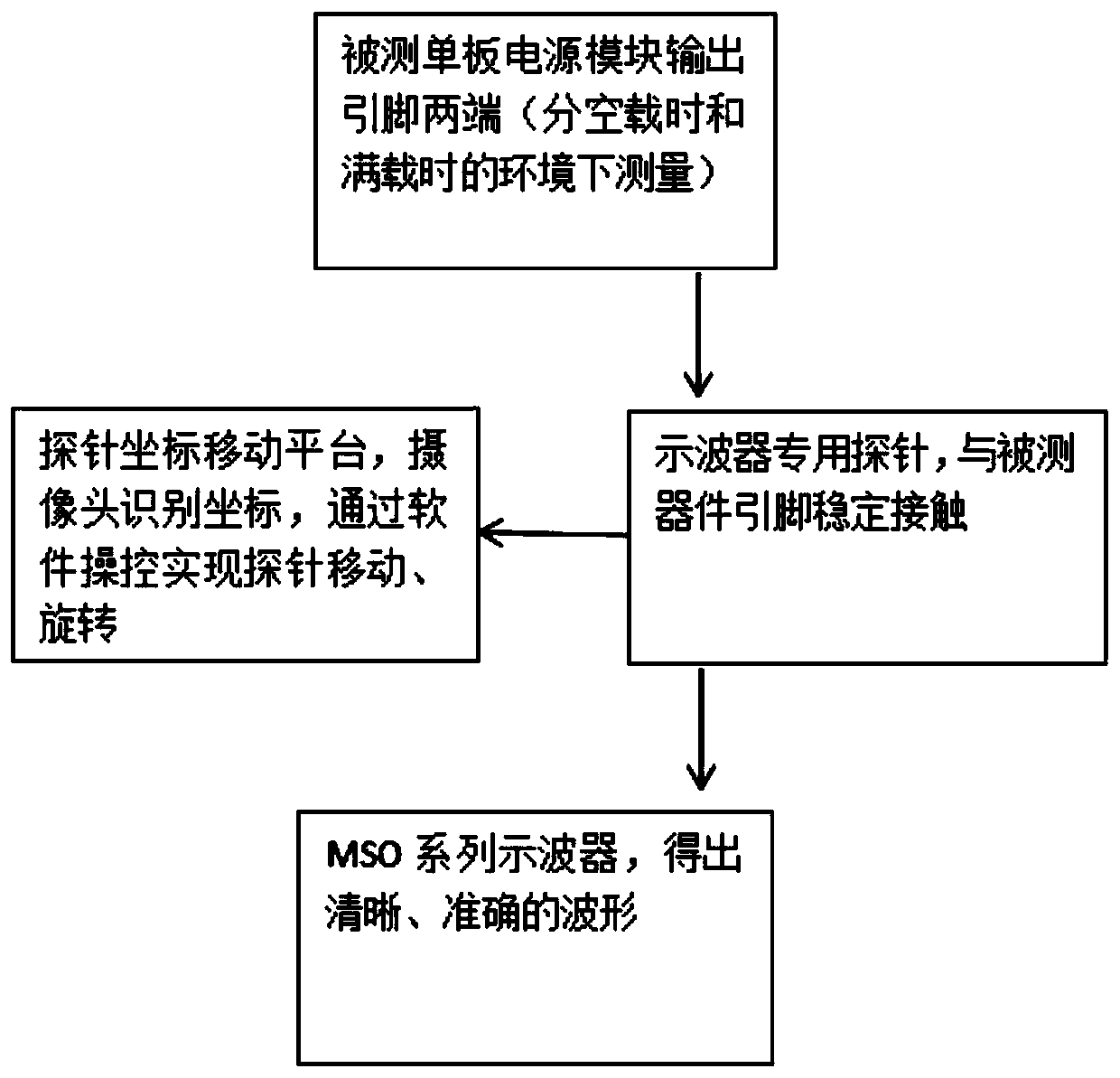

[0026] refer to Figure 1-2 , a method for automatically testing power supply ripple noise, comprising the following steps:

[0027] S1: The oscilloscope must be calibrated first, and the original waveform of the oscilloscope should be correctly debugged before testing;

[0028] S2: Set up the oscilloscope. The oscilloscope probe uses a single-ended passive probe. For signals with small amplitudes, the probe attenuation ratio uses a 1:1 probe;

[0029] S3: Fix the test board on the coordinate moving platform, and the special probe of the oscilloscope is loaded on the coordinate moving platform, which is driven by the motor through the belt drive. The movement of the probe includes three directions: X, Y, and Z;

[0030] S4: Convert the CAD data of the design engineer into a usable test data file;

[0031] S5: Move the two probes to contact with the two solder joints resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com