Drainage Method of Long-distance Tunnel by Horizontal Directional Drilling

A horizontal directional drilling rig and horizontal directional technology, applied in directional drilling, drilling equipment and methods, drilling automatic control system, etc., can solve the problem of being unable to use fixed pumping stations to pump and drain water, and achieve the effect of large borehole diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

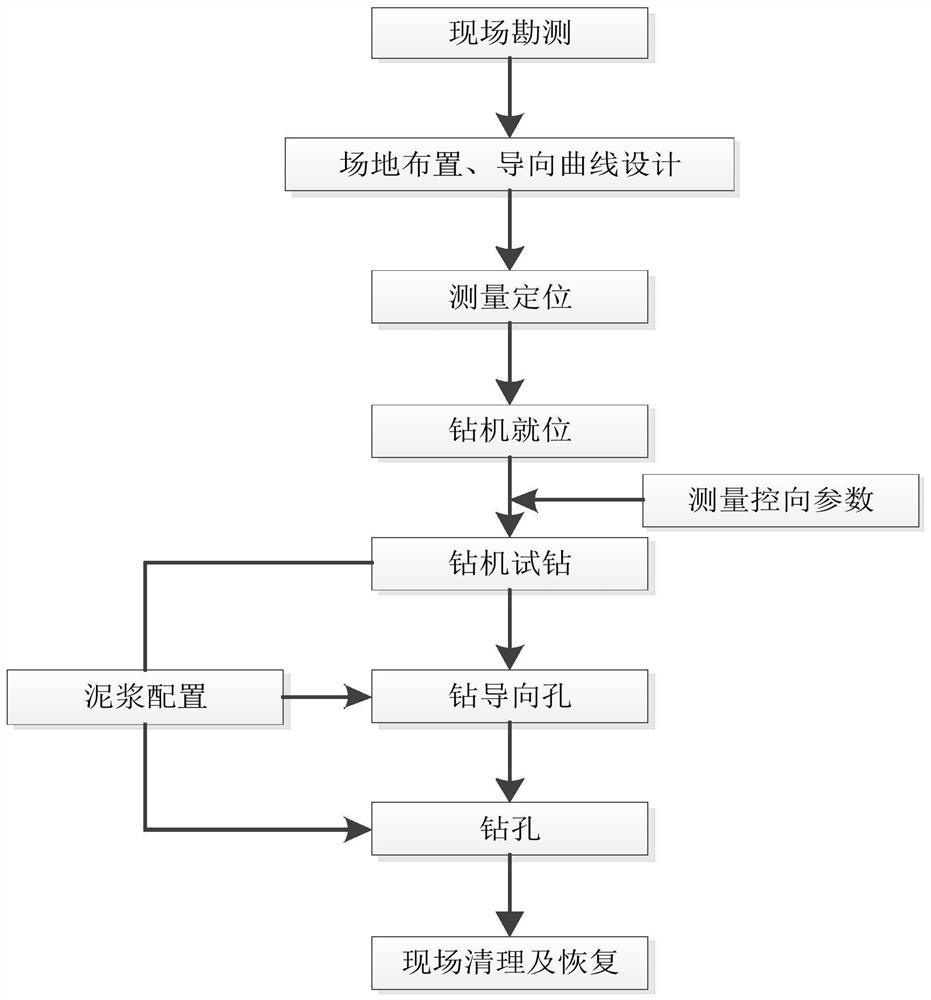

Method used

Image

Examples

Embodiment Construction

[0034] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

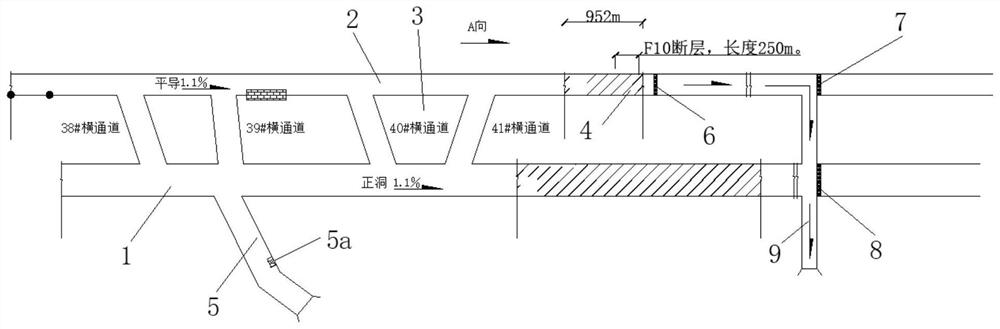

[0035] Such as figure 2As shown, the long-distance tunnel is provided with a main tunnel 1 and a horizontal guide 2, and both the main tunnel 1 and the horizontal guide 2 include the excavated section, the section to be excavated and the exit section. The main tunnel 1 and the horizontal guide 2 are connected through a number of transverse passages 3 arranged at intervals along the length of the tunnel. The length of the section to be excavated of the horizontal guide 2 is 952 meters, and the section to be excavated runs through the fault fracture zone 4, the length of which is 250 meters. The main hole 1 is higher than the flat guide 2, and the main hole 1 and the flat guide 2 have a descending slope of 1.1% along the A direction (as shown by the arrow in the figure). At the exit section of the tunnel, there is a horizontal tunnel 9 that runs through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com