Method for dyeing textile substrate containing residual oligomers

A dyeing method and oligomer technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of reducing waste water discharge, equipment pollution, stain formation, etc., and achieve the effect of improving the degree of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

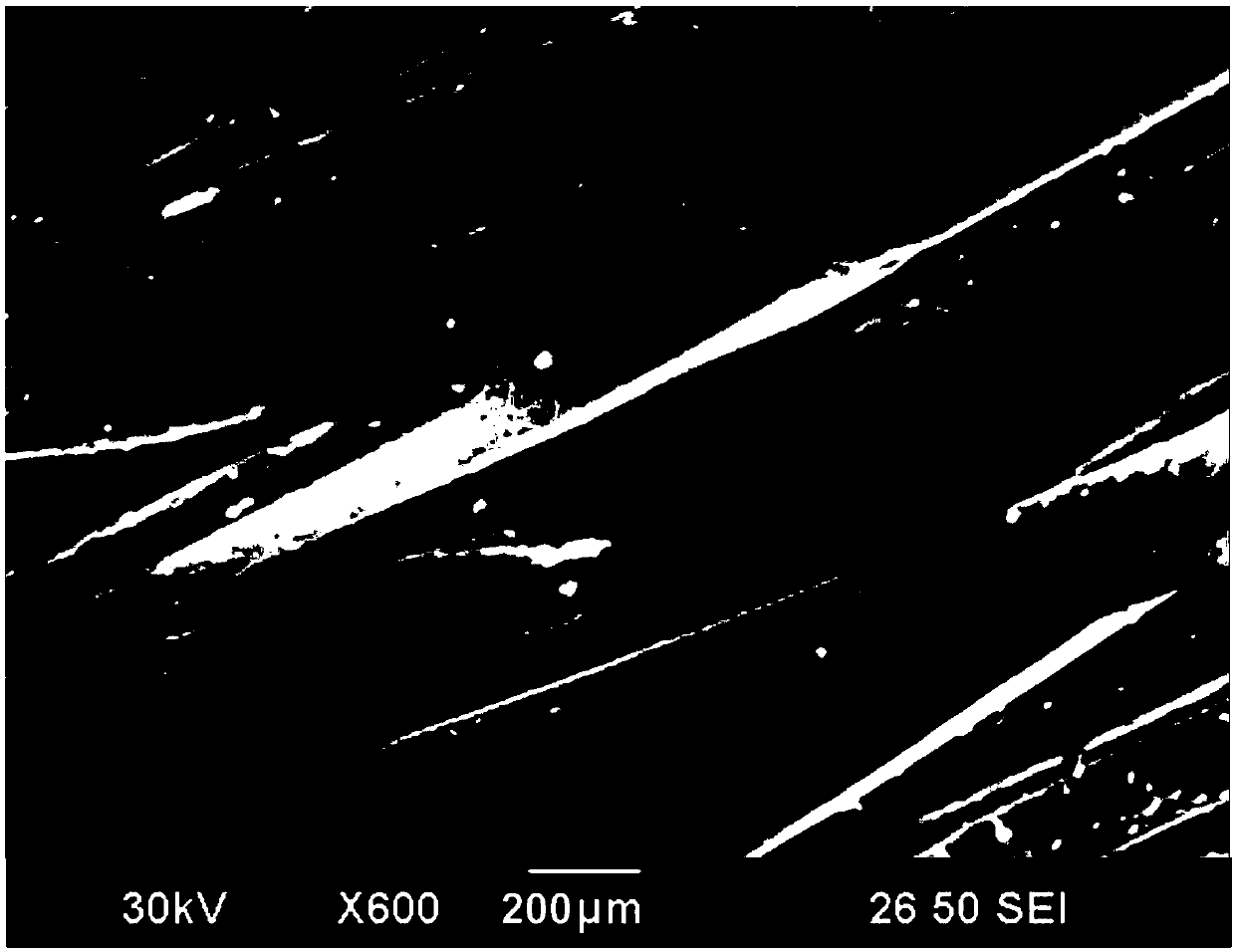

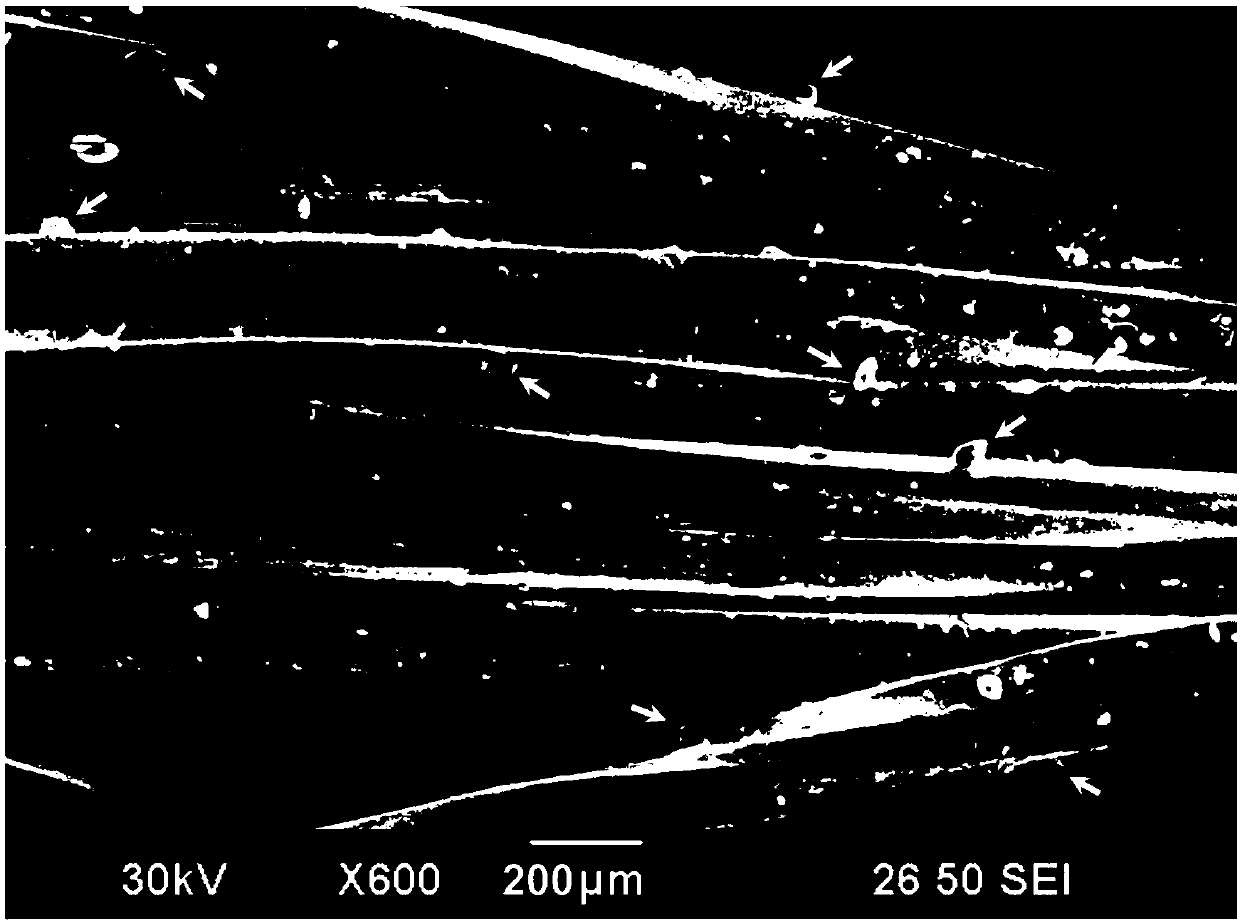

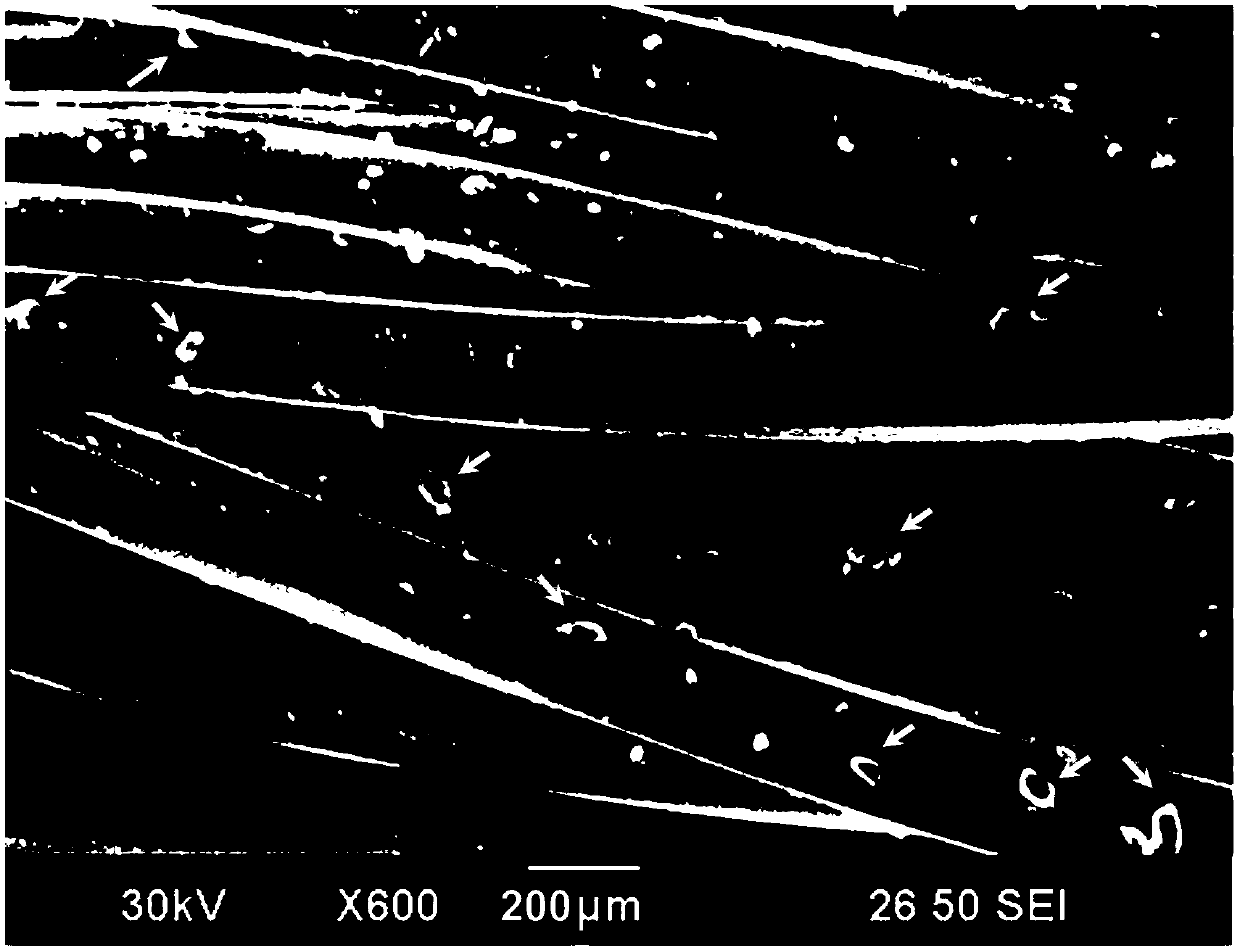

Image

Examples

Embodiment 1

[0022] The steps of the method of embodiment 1 are as follows:

[0023] (a) 10 g of polyester fabric (purchased from Far Eastern New Century Co., Ltd., model number 75 / 72 SDR) was wound on a stainless steel round rod.

[0024] (b) The microporous membrane of polytetrafluoroethylene (ePTFE, purchased from Yumingtai Chemical Co., Ltd., the model is STF-5126, the size is 15cm×15cm, the thickness is 35mm, and the pore diameter is 0.2-0.8μm) tightly and Completely wrap the polyester cloth covered on the above-mentioned round rod so that the polyester cloth is not exposed, and bind and fix it with cotton thread or nylon thread.

[0025] (c) Put the above-mentioned polyester cloth and microporous membrane fixed on the round rod into an autoclave with a volume of 1L, inject 150±3g of liquid carbon dioxide, heat to 120-130°C under the state of fluid disturbance, and pour Inject gaseous carbon dioxide and pressurize to 250-300bar to form supercritical carbon dioxide and maintain it for...

Embodiment 2 and Embodiment 3

[0028] The method of embodiment 2 and embodiment 3 is similar to embodiment 1, and difference is that in this step (b), respectively use polypropylene microporous membrane (PP, purchased from vanadium company, model is M-PP047N045I, size 15cm×15cm, thickness 47mm, pore diameter about 0.45μm) and polyurethane microporous membrane (PU, purchased from Jiyouli Company, model ITPUC035137, size 15cm×15cm, thickness 35mm, pore diameter 0.2-0.6μm ) to replace ePTFE in Example 1.

Embodiment 4 and Embodiment 5

[0030] The method of embodiment 4 and embodiment 5 is similar to embodiment 1, difference is that in this step (c), before injecting liquid carbon dioxide, embodiment 4 puts 0.05g disperse red 92 (Disperse Red 92) into hot Autoclave, Example 5 First put 0.05g of Disperse Blue 60 (Disperse Blue 60) into the autoclave.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com