Plasma porous structure with hotspot structure and preparation method thereof

A technology of plasma and porous structure, applied in the field of preparation of ionic porous structure, can solve the problems of low density of hot spots and low surface roughness of nanopores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

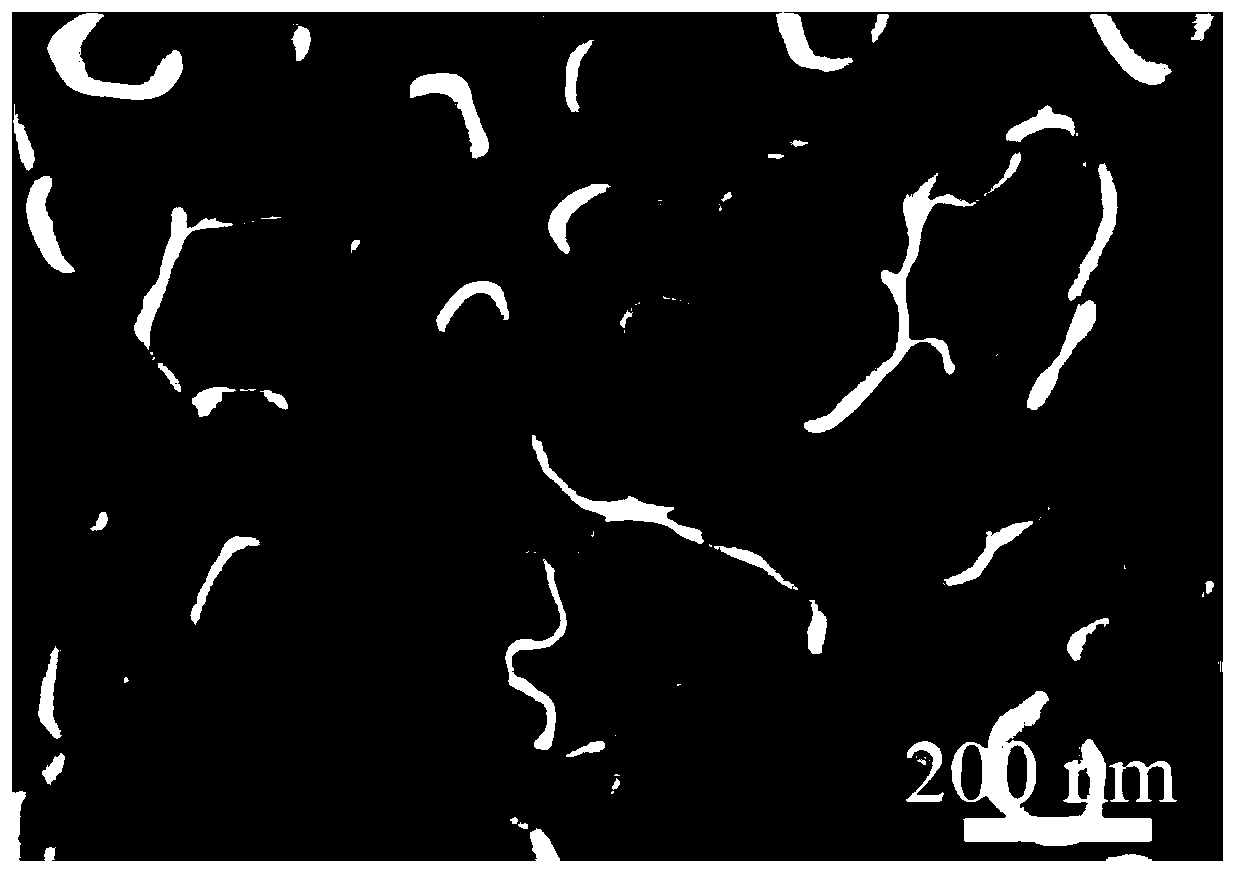

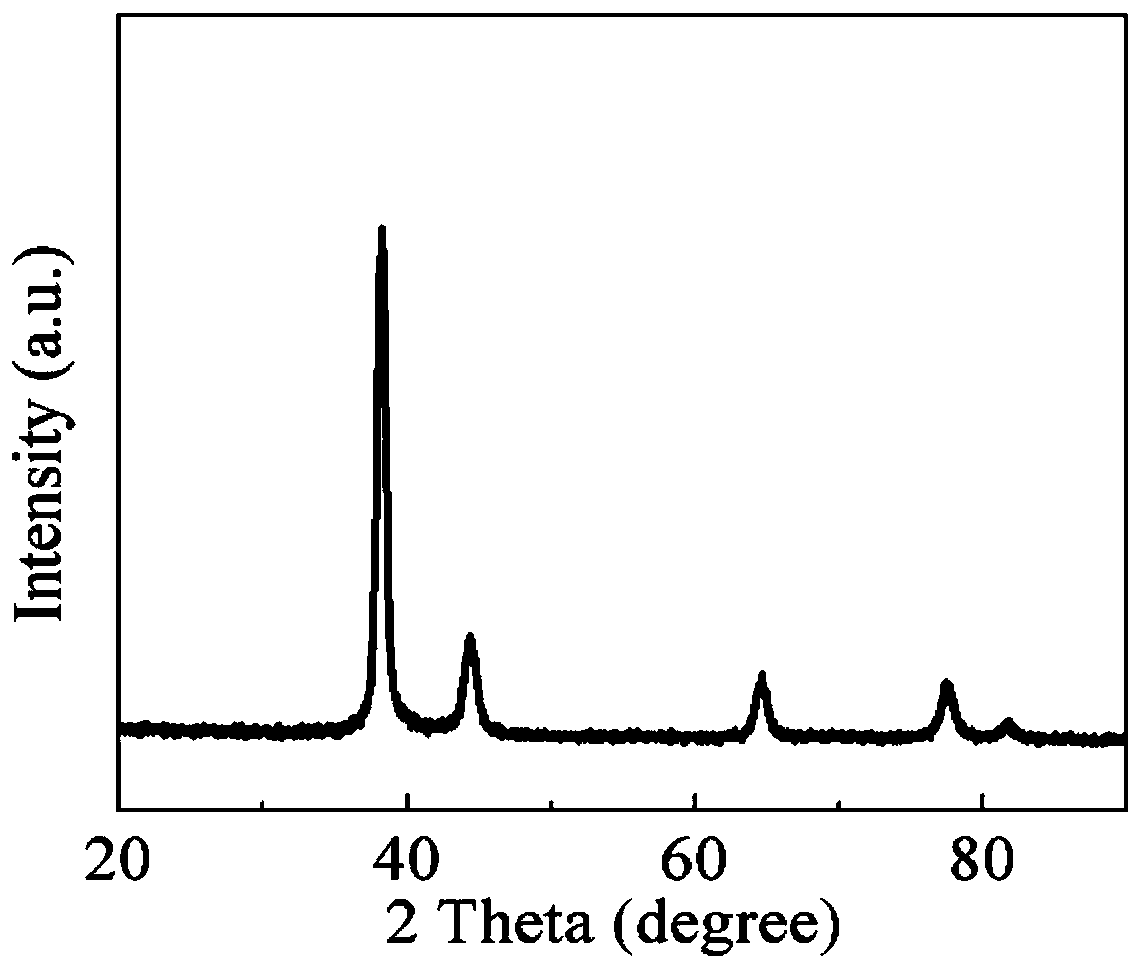

Image

Examples

preparation example Construction

[0040] A method for preparing a plasma porous structure with a hot spot structure, specifically comprising the following steps:

[0041] Step 1: Immerse the silicon wafer in the acetone solution for 5-10 minutes, then take the silicon wafer out of the acetone solution and put it in the ethanol solution for cleaning for 5-10 minutes, take the silicon wafer out of the ethanol solution and put it into the deionized Soak in water for 5-15 minutes, then take the wafer out of deionized water and dry it with nitrogen;

[0042] Step 2: Put the dried silicon wafer into the magnetron sputtering coating equipment and proceed as follows: pump the magnetron sputtering coating equipment to a vacuum and then pass in argon gas, then add a tantalum target and a silver target to blow dry Carry out the magnetron co-sputtering deposition on the silicon wafer after that to prepare the plasma porous structure with hot spot structure according to any one of claims 1 to 5;

[0043] Among them, in st...

Embodiment 1

[0047] As a specific embodiment, the present invention provides a method for preparing a plasma porous structure with a hot spot structure;

[0048] Step 1: Immerse the silicon (100) substrate in an analytically pure acetone solution for 5 minutes, then remove the silicon (100) substrate from the analytically pure acetone solution and wash it in absolute ethanol for 5 minutes, and place the silicon (100 ) the substrate is taken out from the absolute ethanol solution and soaked in deionized water for 5 minutes, then the silicon (100) substrate is taken out from the deionized water and blown dry with 99.5% nitrogen;

[0049] Step 2: Put the dried silicon (100) substrate into the magnetron sputtering coating equipment and perform the following operations: pump the magnetron sputtering coating equipment to a vacuum and then pass in argon gas, and magnetron sputtering coating The temperature of the equipment is controlled at 100°C, the pressure is controlled at 0.1Pa, the flow rate o...

Embodiment 2

[0053] As a specific embodiment, the present invention provides a method for preparing a plasma porous structure with a hot spot structure;

[0054] Step 1: Immerse the silicon (100) substrate in an analytically pure acetone solution for 10 minutes, then remove the silicon (100) substrate from the analytically pure acetone solution and wash it in absolute ethanol for 5 minutes, and place the silicon (100 ) the substrate is taken out from the absolute ethanol solution and soaked in deionized water for 5 minutes, then the silicon (100) substrate is taken out from the deionized water and blown dry with 99.5% nitrogen;

[0055] Step 2: Put the dried silicon (100) substrate into the magnetron sputtering coating equipment and perform the following operations: pump the magnetron sputtering coating equipment to a vacuum and then pass in argon gas, and magnetron sputtering coating The temperature of the equipment is controlled at 150°C, the pressure is controlled at 0.3Pa, the argon ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com