Revolution-type semiconductor evaporation table

An evaporation table and semiconductor technology, applied in the semiconductor field, can solve the problems of low evaporation precision, uneven thickness of metal film, low efficiency of revolution type evaporation table, etc., and achieve high evaporation precision, good evaporation effect and high dryness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples.

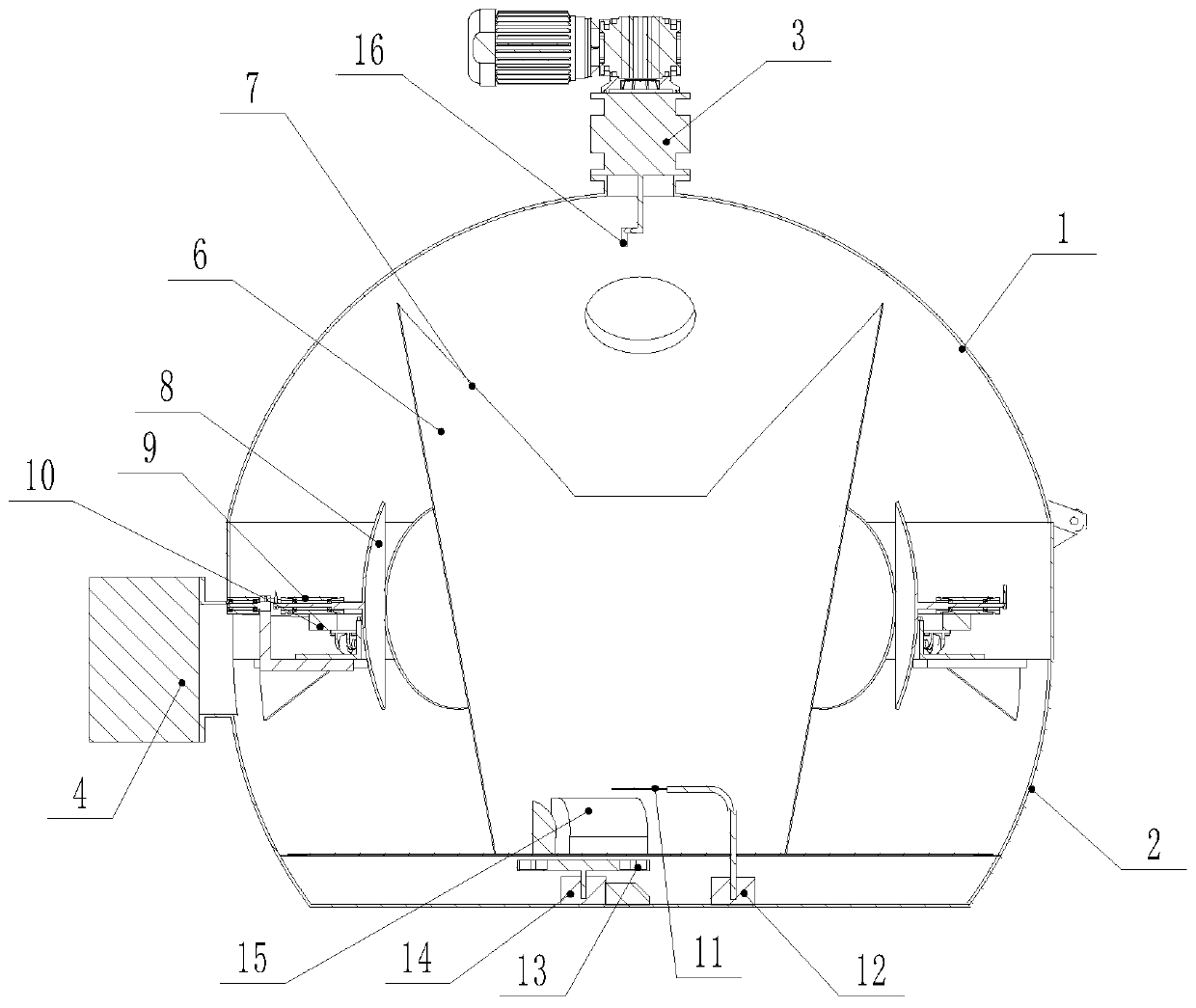

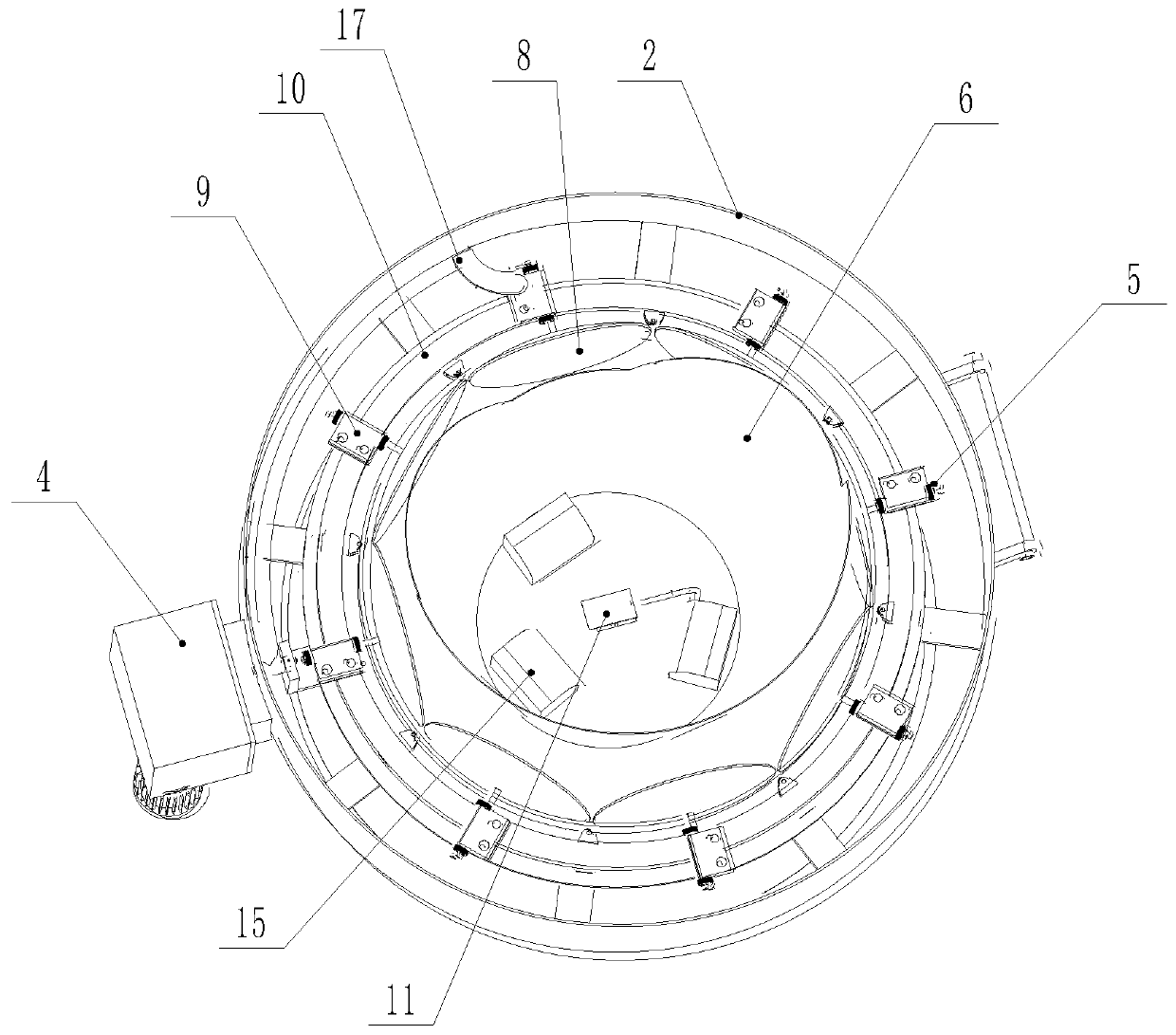

[0034] Such as Figure 1 to Figure 11 As shown, a revolving semiconductor evaporation table includes a lower casing 2 and an upper cover 1. The inner space between the lower casing 2 and the upper cover 1 forms an evaporation chamber, and the bottom of the evaporation chamber is provided with a The crucible 13, the bottom of the shell is provided with an electron beam generating device and a vacuum device for vacuuming the evaporation chamber. Since the electron beam generating device and the vacuum pumping device are conventional structures in the current evaporation table, their structure and principle are clear, so they will not be described in detail here.

[0035] In this embodiment, the number of the crucibles 13 is multiple, preferably six, and the circumference of the multiple crucibles 13 is evenly distributed on the rotating support, and the rotating support is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com