Coking method for improving coke granularity

A technology of coke and particle size, applied in the field of coal chemical industry, achieves the effects of low treatment cost, reduction of cracks in coke and improvement of particle size of coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

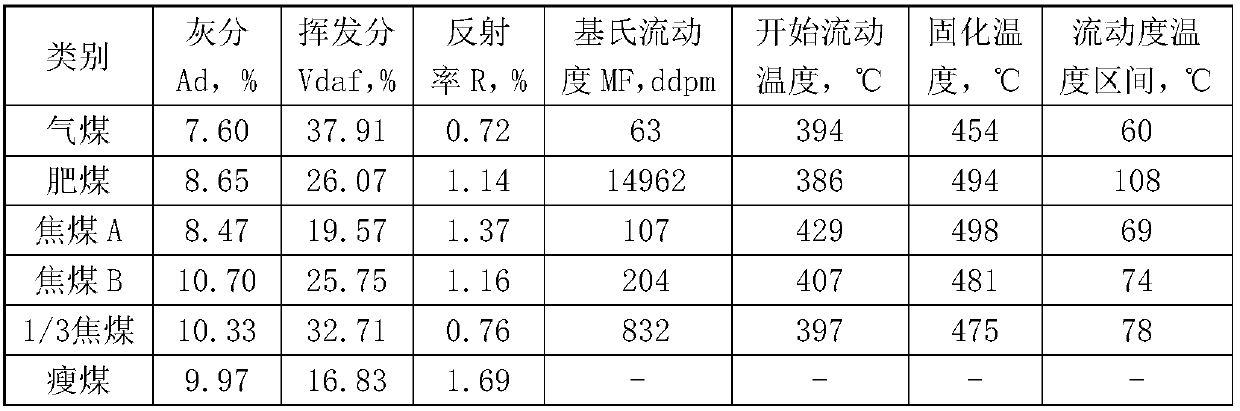

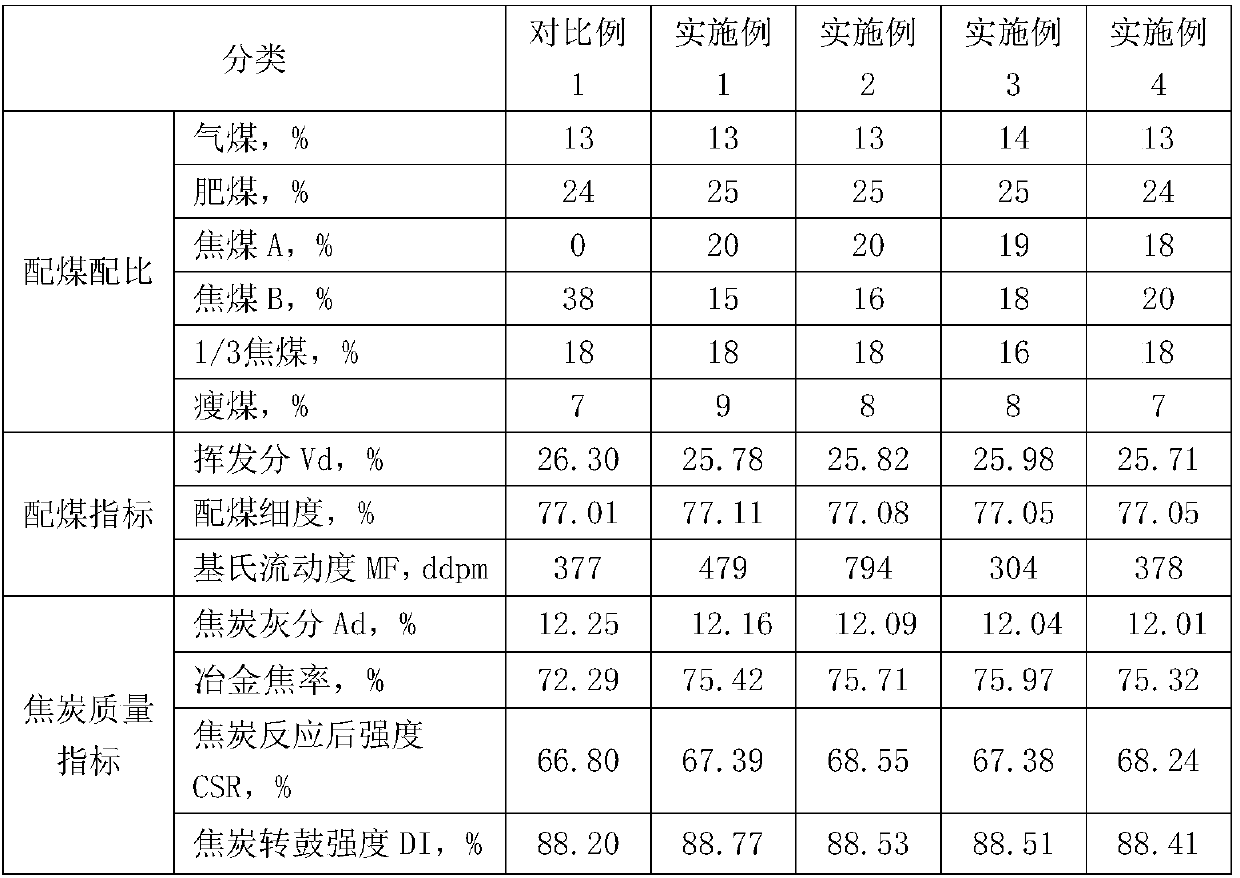

[0024] The present invention will be further described below in conjunction with specific examples, as shown in Table 1-2.

[0025] A coking method for increasing coke particle size, comprising the steps of:

[0026] 1) Detect the coal rock reflectance R of coking coal, and screen out high metamorphic degree coking coal and low metamorphic degree coking coal. The rate R is 1.1-1.3%;

[0027] 2) Detect the MF of the coking coal, pre-crushing the coking coal with the MF ≤ 100ddpm, and control the particle size of the coking coal after crushing to ≤ 3mm;

[0028] 3) Coal blending, high metamorphic degree coking coal, low metamorphic degree coking coal and other coking coals are blended according to the following mass percentages, high metamorphic degree coking coal 15-20%, low metamorphic degree coking coal 15-20%, lean coal 8-12% , 1 / 3 coking coal 15-20%, fat coal 20-25%, gas coal 12-17%, the sum of the mass percentages of each coking coal is 100%; ;

[0029] 4) The mixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com