Method for improving initial fluidity of gypsum self-leveling mortar

A self-leveling mortar and fluidity technology, applied in the direction of flow characteristics, instruments, analysis materials, etc., can solve the problems of mortar shrinkage and cracking, unfavorable mortar construction, affecting mortar strength, etc. The effect of removing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

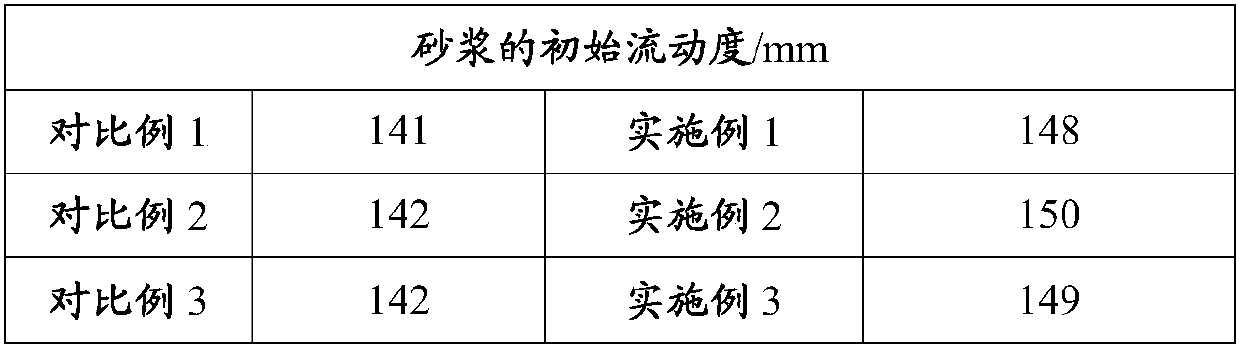

Embodiment 1

[0020] Take 20kg of gypsum self-leveling mortar powder, its standard consistency water consumption is 25%, weigh 5kg of mixing water, add 0.0005g of sodium carbonate in the mixing water, add the mortar powder after the sodium carbonate dissolves and stir for 3min, The stirred mortar is poured into the fluidity test mold and the fluidity of the mortar is tested.

Embodiment 2

[0022] Take 30kg of gypsum self-leveling mortar powder, whose standard consistency is 25% water, weigh 7.5kg of mixing water, add 0.0015g of sodium carbonate to the mixing water, add the mortar powder after the sodium carbonate dissolves and stir for 3 minutes, Pour the stirred mortar into the fluidity test mold and test the fluidity of the mortar.

Embodiment 3

[0024] Take 50kg of gypsum self-leveling mortar powder, whose standard consistency is 25% water, weigh 7.5kg of mixing water, add 0.0020g of sodium carbonate to the mixing water, add the mortar powder after the sodium carbonate dissolves and stir for 4 minutes, Pour the stirred mortar into the fluidity test mold and test the fluidity of the mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com