Material bag unpacking device

A bag-breaking and bag-breaking technology, applied in the field of bag-opening devices, can solve the problems of low operation efficiency, affecting the working efficiency of the bag-opening machine, dust pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

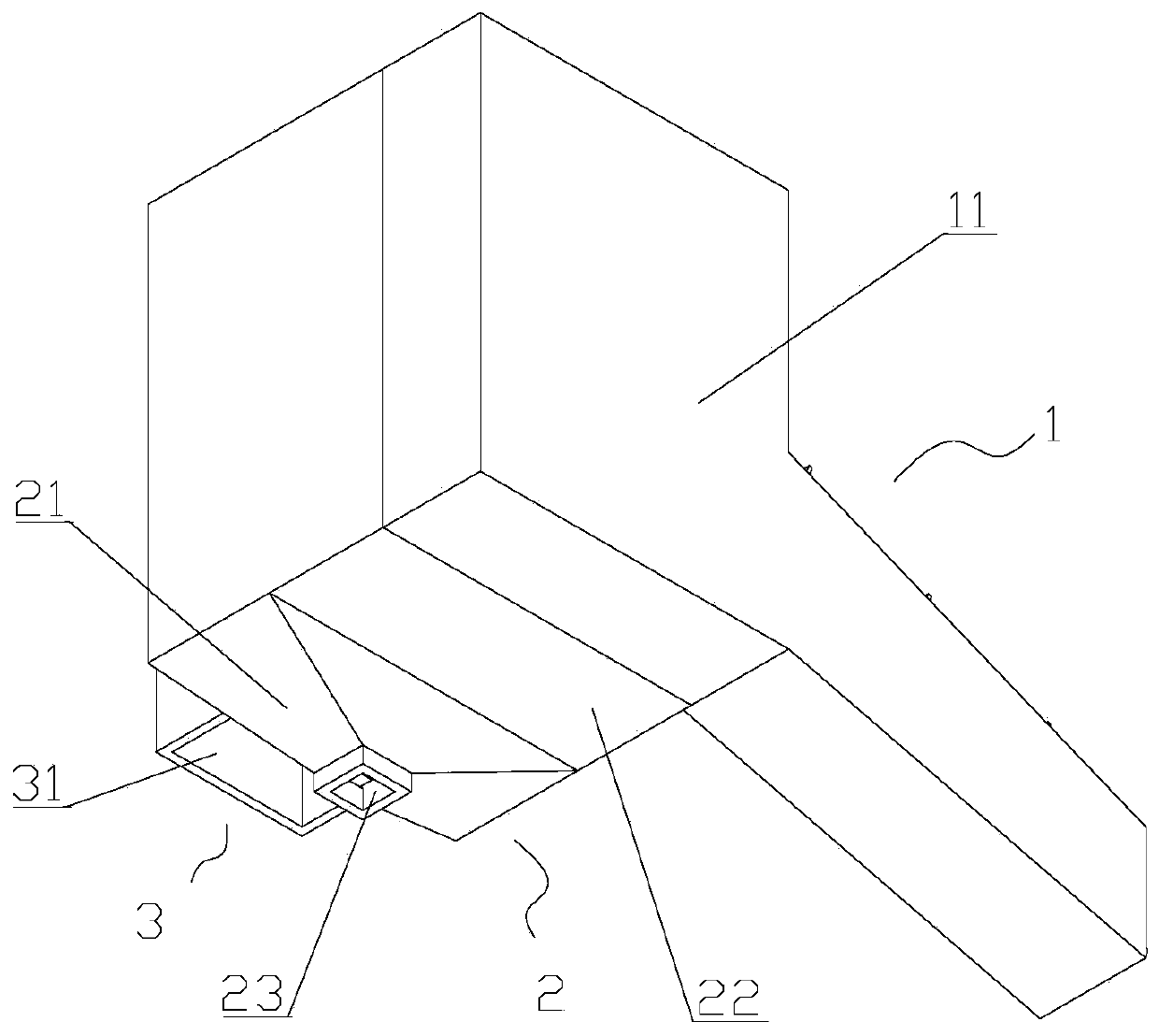

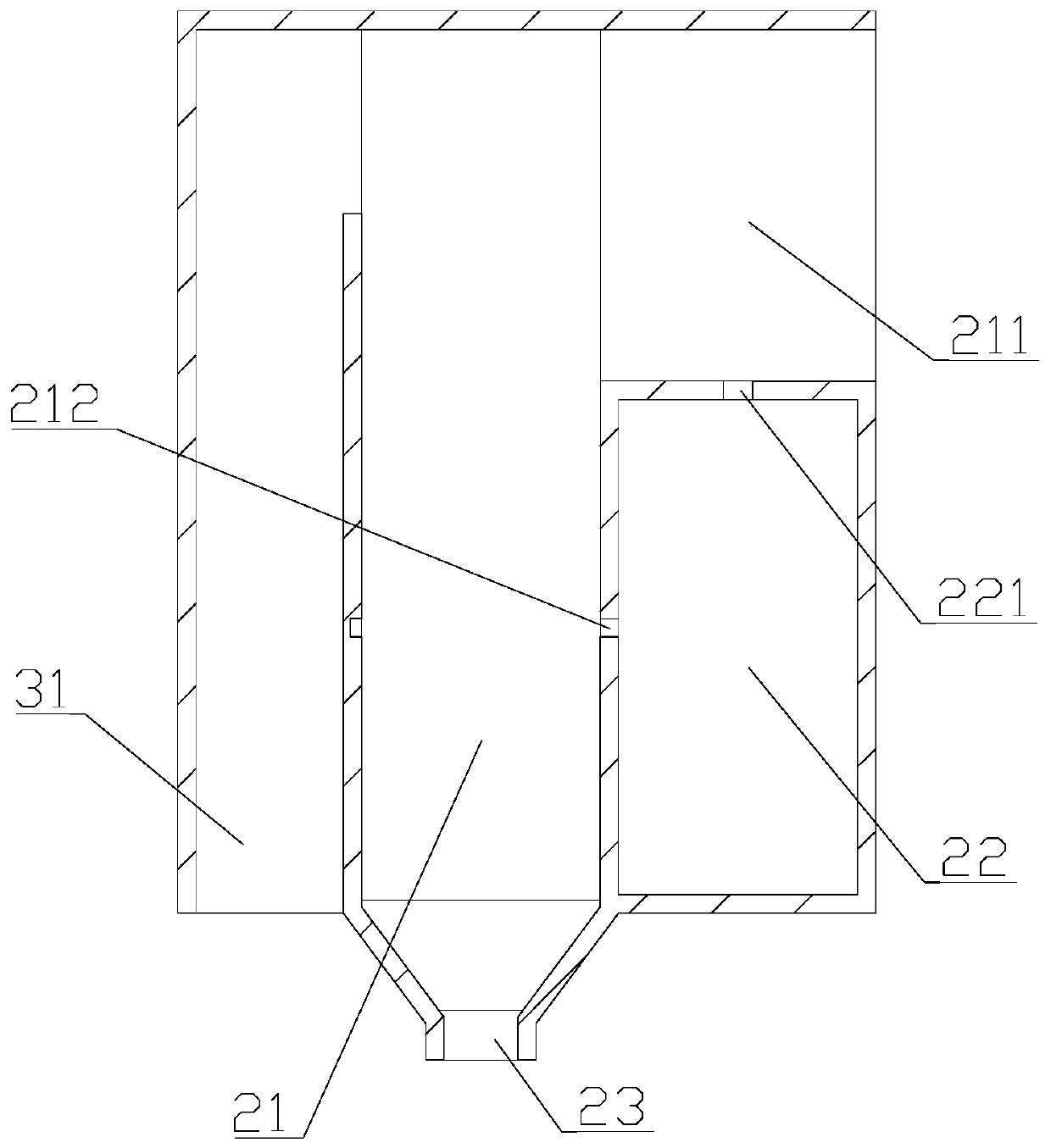

[0047] see Figure 1 to Figure 12 , the embodiment of the present invention provides in order to achieve the purpose of the above invention, the present invention provides: a bag unpacking device, which includes a feeding mechanism 1, a bag unpacking assembly 2, and a suction component 3 arranged in sequence; the feeding mechanism 1 Including lifting transmission part 12, and the feeding mechanism casing 11 that it is accommodated; The outside of bag unpacking assembly 2 and suction part 3 is provided with a main casing; The suction part 3 includes a suction passage 31 arranged in the main casing, and The suction motor in the suction passage 31 is set;

[0048] The specific features of the present invention also have that the main box body includes the bag unpacking cylinder 21 arranged in the middle, and the bag unpacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com