A walnut laser scribing machine based on chain drive

A chain drive, walnut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems that the cutting effect cannot meet the requirements and the walnut adaptability is poor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

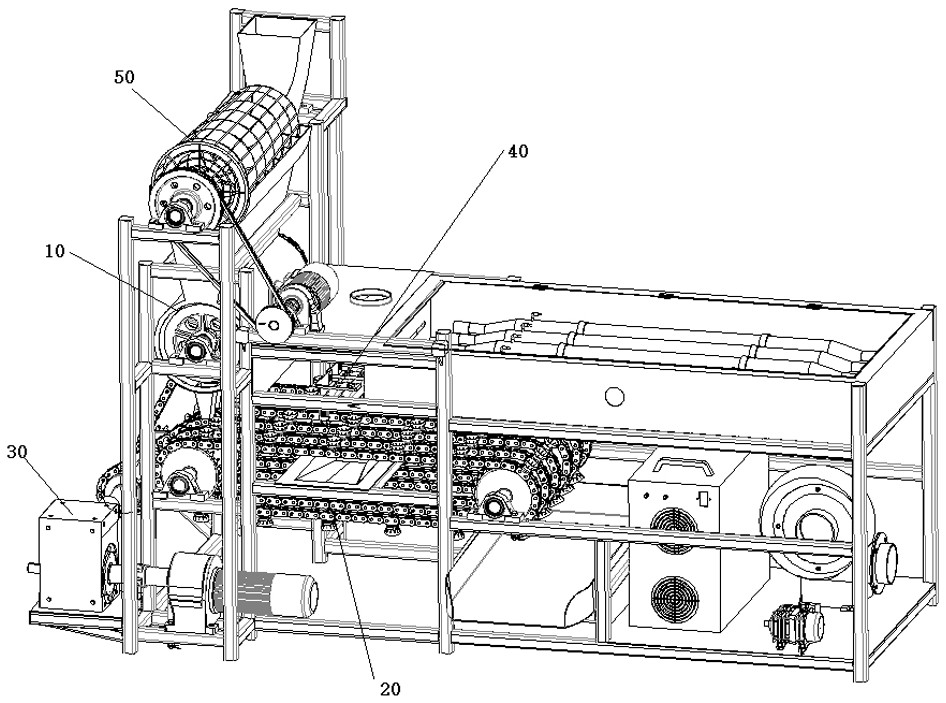

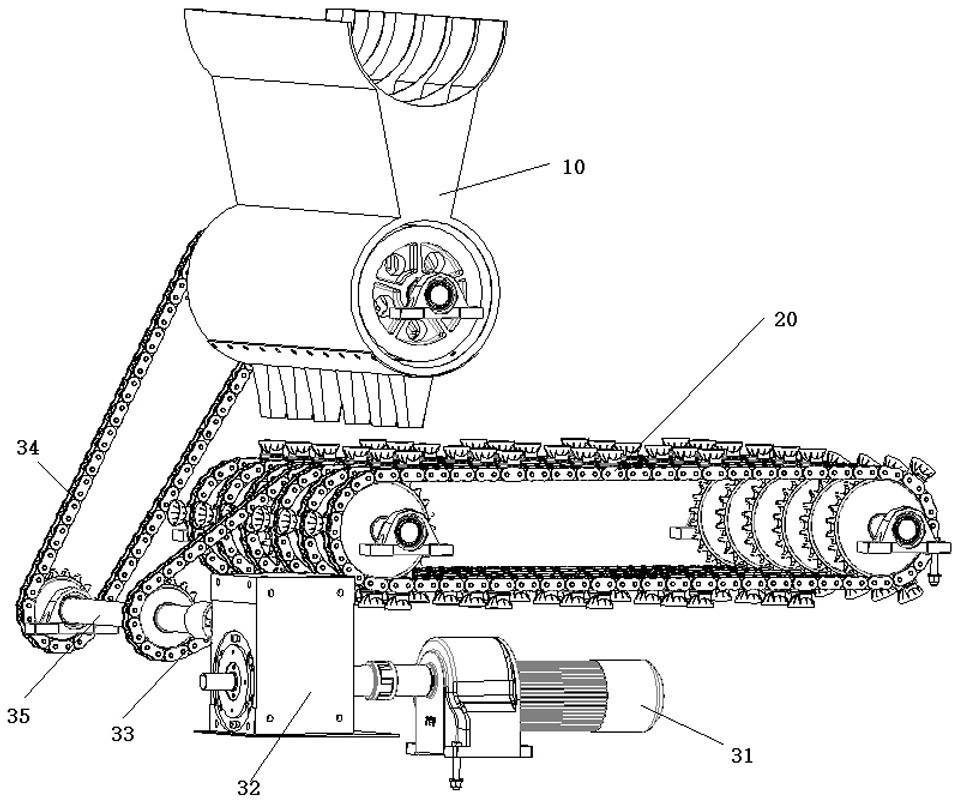

[0037] Such as figure 1 As shown, a chain-driven walnut laser scribing machine includes a feeding device 10 , a feeding device 20 , a laser scribing device 40 and a grading device 50 .

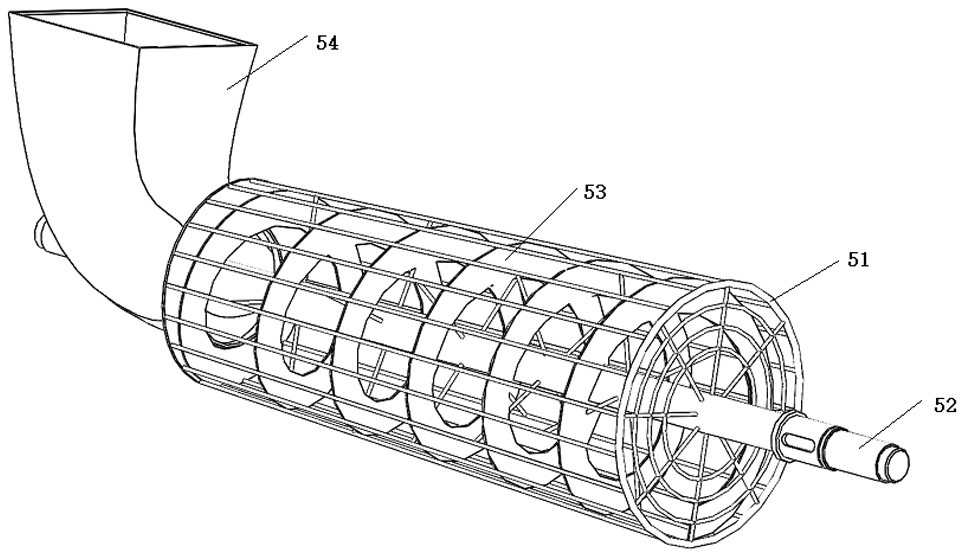

[0038] Such as figure 2As shown, the grading device 50 includes a grid roller 51, a roller shaft 52, a screw blade 53, and a feed hopper 54. The grid roller 51 is in the shape of a frustum of a cone, and its conical surface is uniformly arranged with several grids around its circumference. There is a core drop gap between two adjacent grid bars. The spiral blade 53 is fixedly arranged in the grid drum 51. The roller shaft 52 is used to drive the grid drum 51 to rotate. The small diameter end of the grid drum 51 is provided with a The feeding hopper 54 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com