Converter valve for room temperature magnetic refrigerator and room temperature magnetic refrigerator thereof

A room temperature magnetic refrigerator and diverter valve technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low reliability, large noise and heat of electromagnetic valves, large volume, etc., and achieve simple structure and integrated The effect of high degree of simplification and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description fully illustrates the specific embodiments of the present invention to enable those skilled in the art to practice and reproduce.

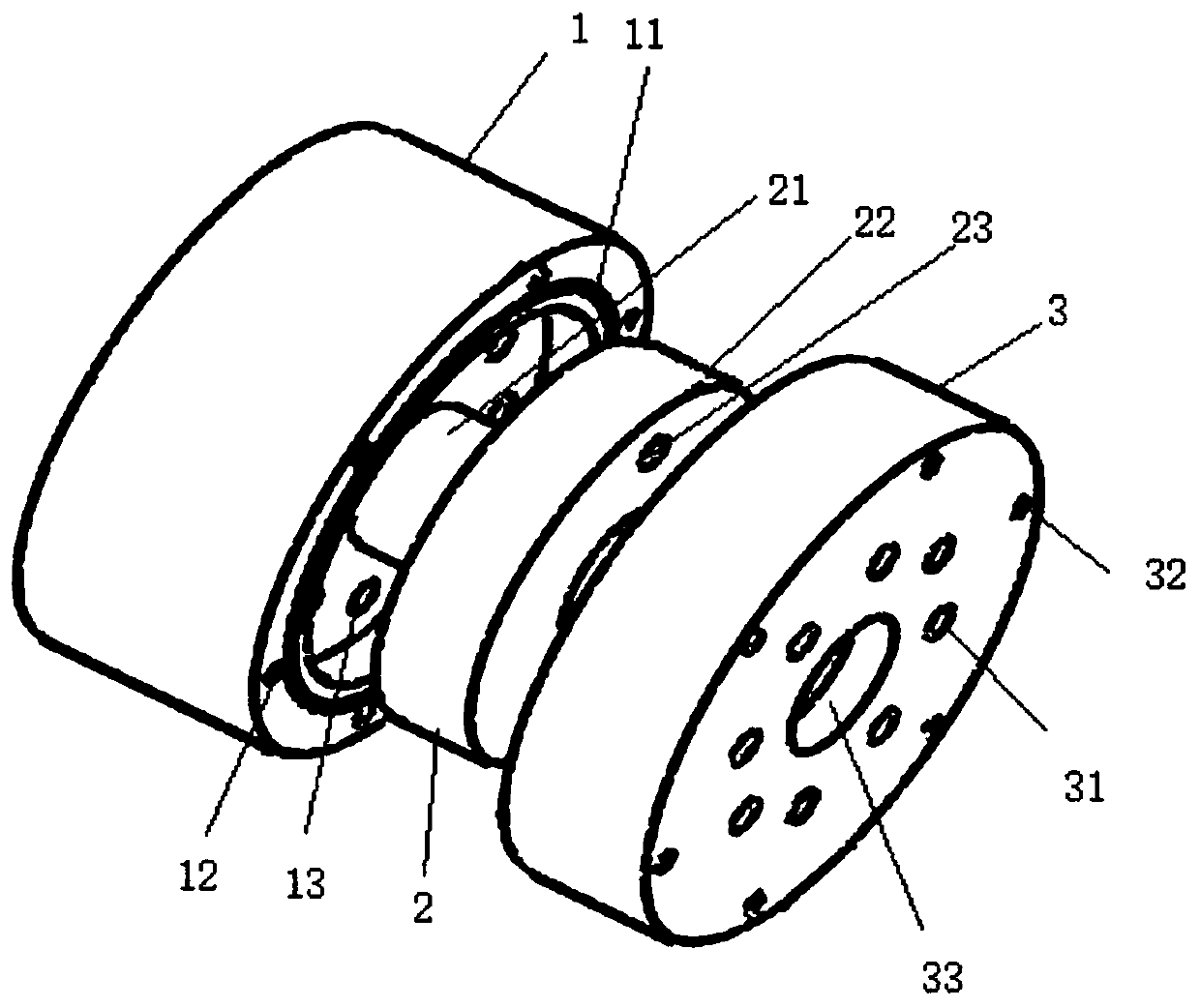

[0023] Such as figure 1 Shown is an exploded view of the structure of the inverter valve for the room temperature magnetic refrigerator in the present invention.

[0024] The structure of the inverter valve for a room temperature magnetic refrigerator includes: a first valve body 1, a valve core 2, and a second valve body 3.

[0025] The outer shape of the first valve body 1 is cylindrical. The inner end surface of the valve body 1 is provided with a first sealing groove and 6 evenly distributed connecting threaded holes 12, the first sealing groove is located inside the connecting threaded hole 12, and the first sealing groove A sealing ring 11 is installed inside; a first valve core recess is provided inside the first sealing groove, and the first valve core recess is provided with 8 uniformly distributed first fluid th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com