Assembling type composite floor slab with height limiting device and production process for assembling type composite floor slab

A technology for stacking floor slabs and a production process, applied in the field of construction, can solve the problems of wasting concrete, difficult to determine the pouring height, and difficulty in demoulding the stacking floor slabs, and achieves the effect of reducing the difficulty of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

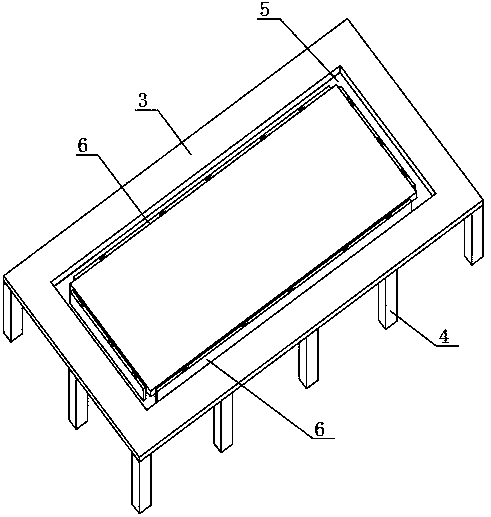

[0036] Such as figure 1 and 2 As shown, a prefabricated laminated floor slab with a height-limiting device has transverse steel bars 10 and longitudinal steel bars 11 poured into the laminated floor, truss steel bars 1 are poured and fixed on the laminated floor, and several vertical steel bars 1 are fixed on the laminated floor. The height-limited columns 2 are all equal in height and their tops are higher than the truss reinforcement 1. The material of the height-limiting column 2 is a steel bar with a diameter of 6-12mm, and the transverse steel bar 10, the longitudinal steel bar 11 and the truss steel bar 1 are all made of Q235 material.

[0037] The production process of the above-mentioned prefabricated laminated floor slab with height limiting device is as follows:

[0038] a. Mold table cleaning. Move the mold table 3 to the cleaning machine of the PC production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com