Environment-friendly waste paper regeneration treatment device

A processing device and technology for waste paper, applied in fiber raw material processing, papermaking, textiles and papermaking, etc., can solve problems such as affecting the production efficiency of users and poor crushing effect of waste paper, and achieve low noise, good crushing effect, and good noise reduction. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

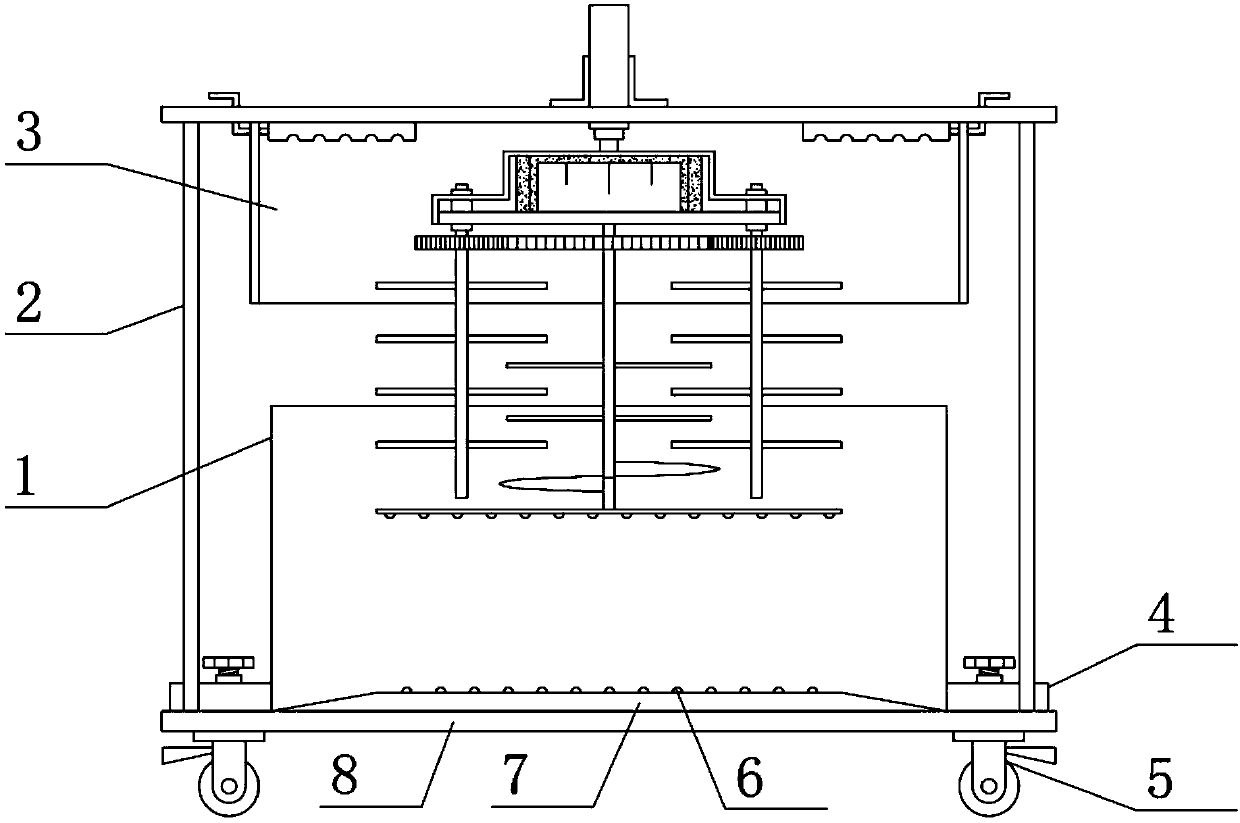

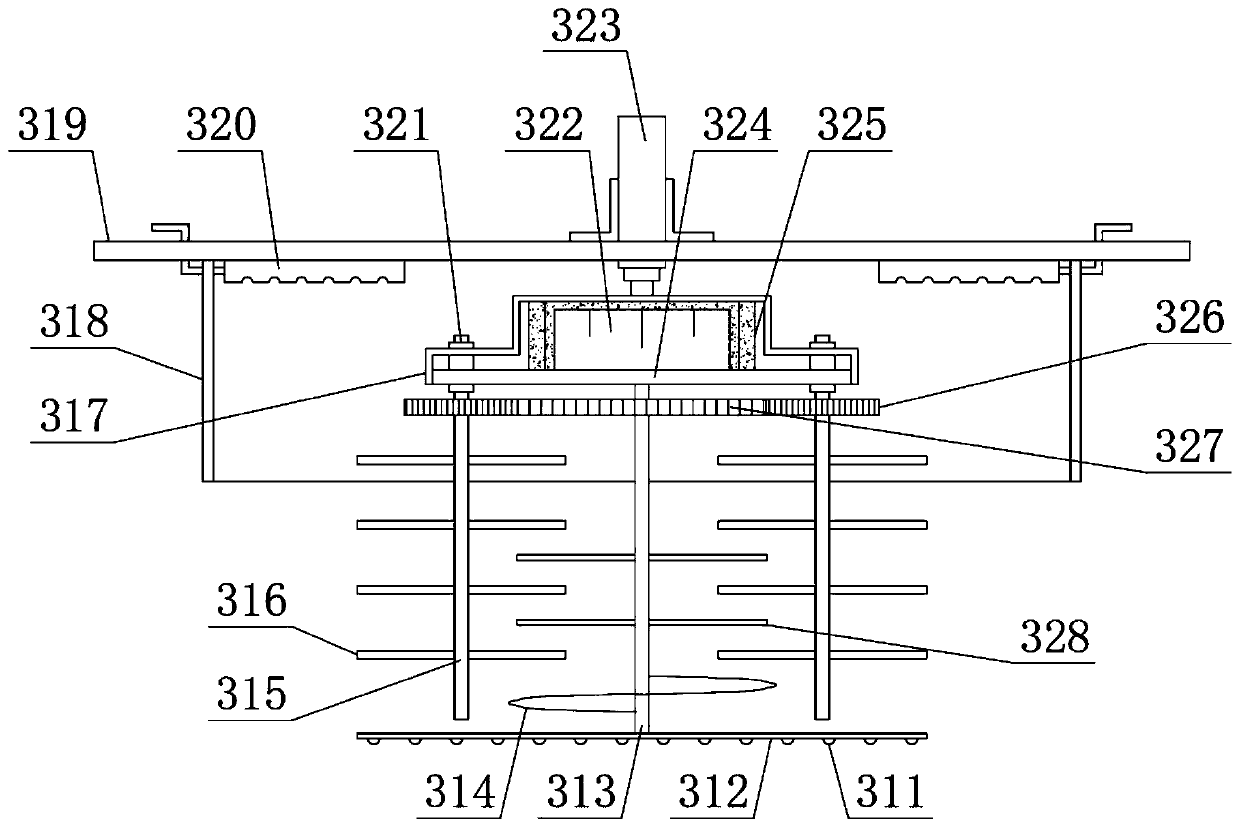

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: an environmentally friendly waste paper regeneration treatment device, including a first support plate 8, a crushing box 1 is welded on the upper surface of the first support plate 8, and outlets are welded on both sides of the crushing box 1. Barrel 4, the top of first support plate 8 is provided with crushing mechanism 3, and crushing mechanism 3 comprises second support plate 319, and the joint of second support plate 319 and first support plate 8 is welded with support member 2, and the second support The two ends of the lower surface of the plate 319 are welded with water outlet pipes 320, the second support plate 319 is provided with a third support plate 324, the upper surface of the third support plate 324 is welded with a drive motor 322, and the output end of the drive motor 322 is welded with a The first transmission rod 313, the two sides of the first transmission rod 313 are welde...

Embodiment 2

[0028] On the basis of Embodiment 1, in order to prevent waste paper from overflowing during crushing, in this embodiment, preferably, the lower surface of the second support plate 319 is also provided with a protective cover 318 corresponding to the crushing box 1, and the protective cover 318 The length and the installation method are not limited. In this embodiment, preferably, the material of the protective cover 318 is rubber, and the two ends of the protective cover 318 and the third support plate 324 are bonded and connected by glue;

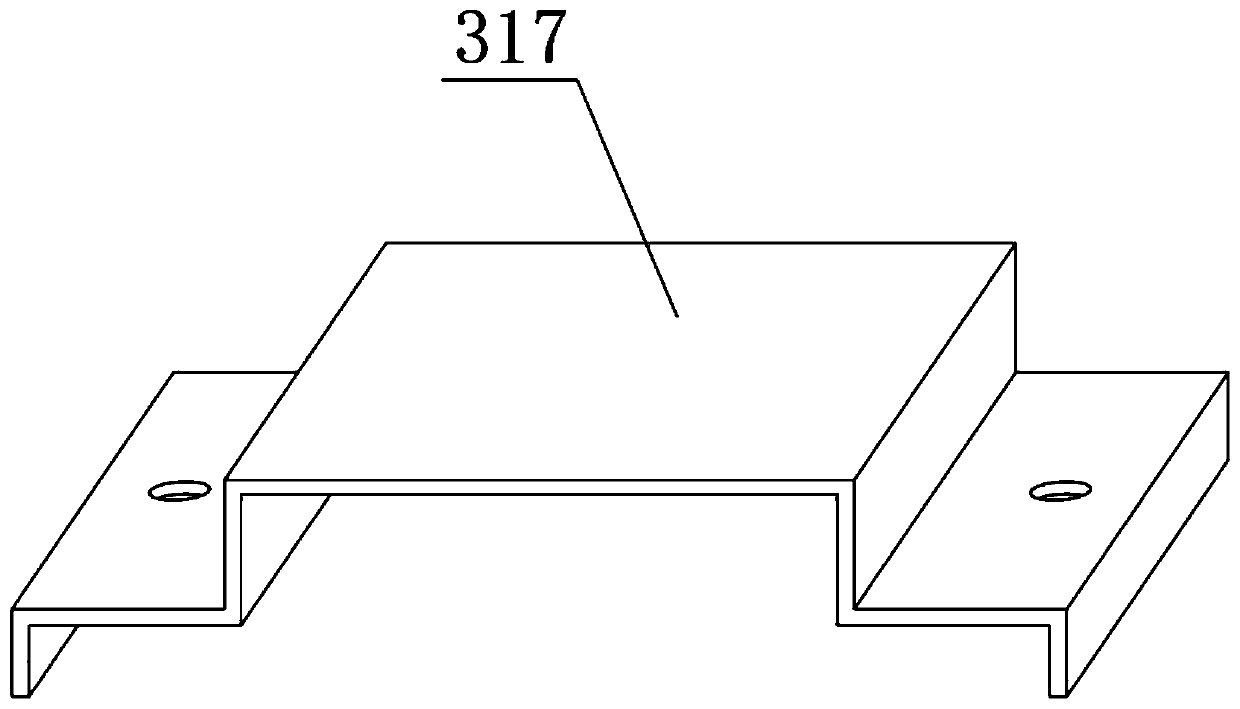

[0029] In order to make the noise reduction effect of the noise reduction sleeve 325 better, in this embodiment, preferably, the noise reduction sleeve 325 is circular, the material of the noise reduction sleeve 325 is sound-absorbing cotton, and the top of the noise reduction sleeve 325 It is connected with the limit cover 317 by glue, and the noise generated by the driving motor 322 is absorbed by the noise reduction sleeve 325 during us...

Embodiment 3

[0033] On the basis of Embodiment 2, in order to make the processing device have a better crushing effect on waste paper, in this embodiment, preferably, the end of the first transmission rod 313 away from the drive motor 322 is provided with a second grinding member 312, the second The second grinding piece 312 is fixedly connected to the first transmission rod 313 by welding, and the lower surface of the second grinding piece 312 is provided with a second grinding protrusion 311, and the shape of the second grinding protrusion 311 is not limited. In this embodiment, Preferably, the second grinding protrusion 311 is hemispherical, and the second grinding protrusion 311 and the second grinding piece 312 are integrally formed;

[0034] In order to make the grinding effect of the second grinding piece 312 on waste paper better, in this embodiment, preferably, the bottom end of the crushing box 1 is welded with the first grinding piece 7 corresponding to the second grinding piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com