Black knitted fabric vat-replenishing dyeing process

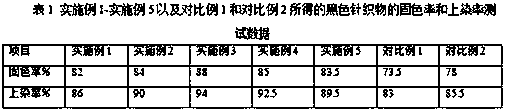

A knitted fabric and black technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of wasting dyes and auxiliaries, increasing the burden of wastewater treatment, losing water and heat, etc., achieving stable coloring, improving dyeing rate and solidity Color rate, enhance the effect of color fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A continuous cylinder dyeing process for black knitted fabrics, comprising the following steps:

[0023] S1 Knitted fabric ingredients: fully soak 600kg of pre-treated knitted fabric at a temperature of 35°C for 10 minutes, and add 600*8=4800L of clean water to the dyeing machine according to the preset liquor ratio of 1:8;

[0024] S2 Dyeing pretreatment: raise the temperature of the above-mentioned dyeing machine to the first set temperature at a heating rate of 3°C / min, then add 80g / L salt, 20g / L accelerator, and 2g / L leveling agent to run for 15min;

[0025] S3 dyeing: add 20g / L black reactive dye to the above dyeing machine, run it for 10min, then raise the temperature of the dyeing machine to the second set temperature at a heating rate of 1°C / min, keep it warm for 30min, and obtain the black knitted fabric dyed for the first time ;

[0026] S4 Continue dyeing cloth: 80g / L*900L=72kg salt, 20g / L*900L=18kg accelerator, 2g / L*900L=1.8kg leveling agent, 20g / L*900L*0.8...

Embodiment 2

[0033] A continuous cylinder dyeing process for black knitted fabrics, comprising the following steps:

[0034] S1 Knitted fabric ingredients: fully soak 700kg of pre-treated knitted fabric for 13 minutes at a temperature of 37°C, and add 5600L of clean water to the dyeing machine;

[0035] S2 Dyeing pretreatment: raise the temperature of the above dyeing machine to the first set temperature at a heating rate of 3°C / min, then add 80g / L salt, 20.2g / L accelerator and 2.2g / L leveling agent and run for 15min ;

[0036] S3 dyeing: add 20g / L black reactive dye to the above dyeing machine, run it for 10min, then raise the temperature of the dyeing machine to the second set temperature at a heating rate of 1°C / min, keep it warm for 30min, and obtain the black knitted fabric dyed for the first time ;

[0037] S4 Continuing Dyeing Cloth: Through calculation, add 84kg of salt, 21.21kg of accelerator, 2.31kg of leveling agent, 15.12kg of black reactive dye and 1050L of clean water to ad...

Embodiment 3

[0044] A continuous cylinder dyeing process for black knitted fabrics, comprising the following steps:

[0045] S1 Knitted fabric ingredients: fully soak 800kg of pre-treated knitted fabrics at a temperature of 40°C for 17 minutes, and add 6400L of clean water to the dyeing machine;

[0046] S2 Dyeing pretreatment: raise the temperature of the above dyeing machine to the first set temperature at a heating rate of 3°C / min, then add 80g / L salt, 20.4g / L accelerator and 2.4g / L leveling agent and run for 18min ;

[0047] S3 Dyeing: Add 20kg / L black reactive dye to the above dyeing machine, run it for 18 minutes, then raise the temperature of the dyeing machine to the second set temperature at a heating rate of 1°C / min, keep it warm for 37 minutes, and obtain the black knitted fabric dyed for the first time ;

[0048] S4 Continuing Dyeing Cloth: Through calculation, add 96kg of salt, 24.48kg of accelerator, 2.88kg of leveling agent, 17.28kg of black reactive dye and 1200L of clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com