Composite acetate fiber non-woven material applicable to cigarette filters and preparation method and application of composite acetate fiber non-woven material

A non-woven material, acetate fiber technology, used in non-woven fabrics, applications, carbon fibers, etc., can solve the problems of poor smoke suction uniformity, high smoke temperature, and limited market promotion, and achieve strong heat conduction and heat absorption capabilities. , the effect of increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

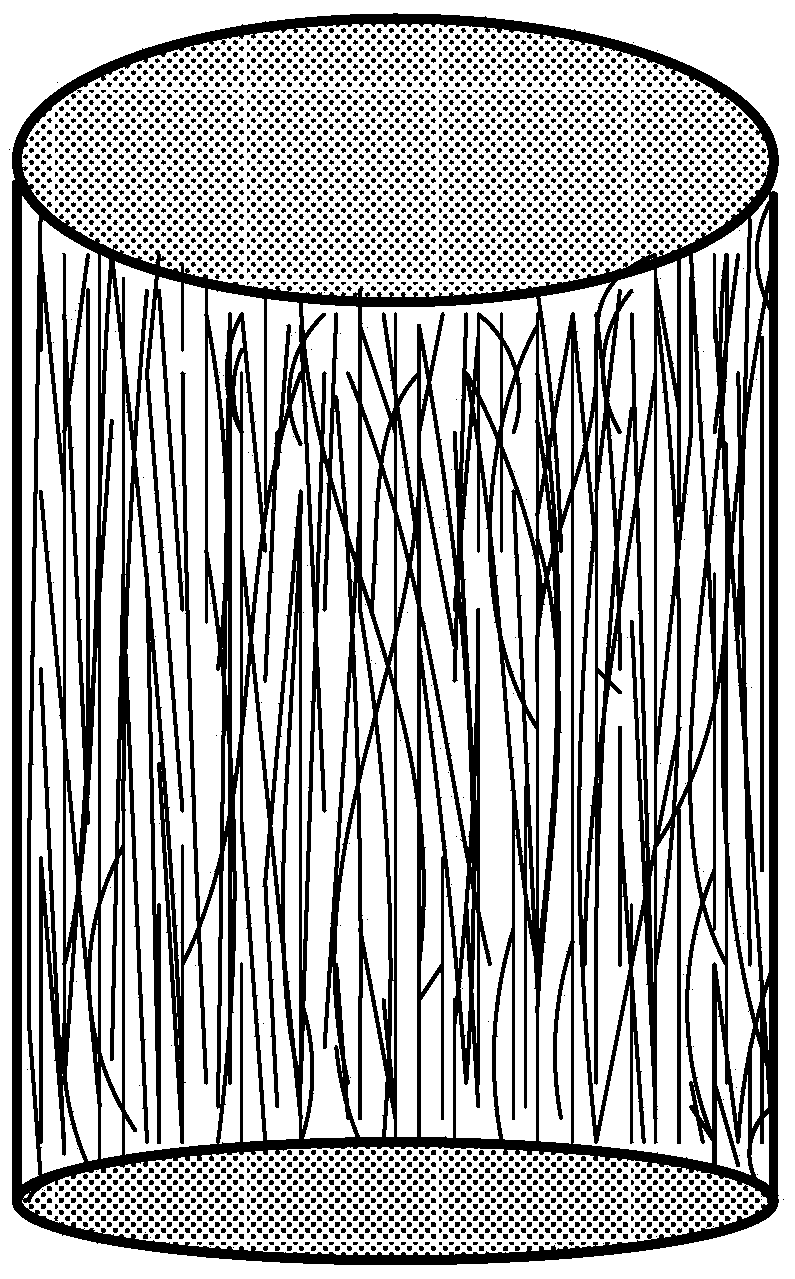

[0047] The fineness of the acetate fiber in the composite acetate fiber nonwoven material of this embodiment is 3 deniers, and the fineness of the polylactic acid fibers is 1.56 deniers. The mass ratio of the polylactic acid fiber is 10%, and the mass ratio of the acetate fiber is 90%.

[0048] The acetate fiber has a Y-shaped cross section and an average length of 38 mm; the polylactic acid fiber has an average length of 38 mm and a circular cross section.

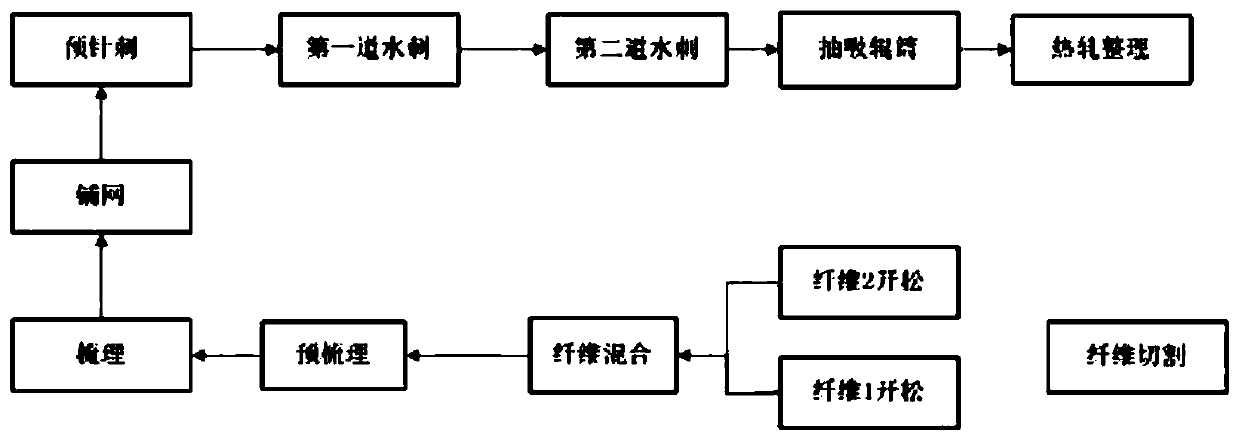

[0049] The preparation method of described composite acetate fiber nonwoven material is as follows:

[0050] The acetate fiber and the polylactic acid fiber are opened and mixed according to the above-mentioned proportions set, and then pre-carded on a cotton-type carding machine. The basic parameters of carding are set: the speed of the cotton roller is 0.43r / min; the speed of the licker-in roller is 578.13r / min; the speed of the cylinder is 555.00r / min; the speed of the doffer is 7.71r / min; the speed of the net is 4.07...

Embodiment 2

[0061] The fineness of the acetate fiber in the composite acetate fiber nonwoven material of this embodiment is 3 deniers, and the fineness of the polylactic acid fibers is 1.56 deniers. The mass ratio of the polylactic acid fiber is 50%, and the mass ratio of the acetate fiber is 50%.

[0062] The acetate fiber has a Y-shaped cross section and an average length of 38 mm; the polylactic acid fiber has an average length of 38 mm and a circular cross section.

[0063] The preparation method of described composite acetate fiber nonwoven material is as follows:

[0064] The acetate fiber and polylactic acid fiber are opened and mixed according to the set ratio, and then pre-carded on a cotton-type carding machine. The basic parameters of carding are set: the speed of the cotton roller is 0.45r / min; the speed of the licker-in roller is 580.07r / min; the speed of the cylinder is 560.00r / min; the speed of the doffer is 7.8r / min; the speed of the net is 3.92r / min; One-time carding, b...

Embodiment 3

[0075] The fineness of the acetate fiber in the composite acetate fiber nonwoven material of this embodiment is 8 denier, and the diameter of the stainless steel fiber is 8 μm and 30 denier.

[0076] The proportion of the stainless steel fiber is 35%; the mass proportion of the polylactic acid fiber is 0, and the mass proportion of the acetate fiber is 65%.

[0077] The acetate fiber has a Y-shaped cross section with an average length of 38 mm; the stainless steel fiber has a length of 55 mm and a circular cross section.

[0078] The preparation method of described composite acetate fiber nonwoven material is as follows:

[0079] The acetate fiber and stainless steel fiber are opened and mixed according to the set ratio, and then pre-carded on a cotton-type carding machine. The basic parameters of carding are set: the speed of the cotton roller is 0.45r / min; the speed of the licker-in roller is 580.07 r / min; the speed of the cylinder is 560.00r / min; the speed of the doffer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com