A high-performance sludge dewatering and drying special equipment

A special equipment, high-performance technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of long cycle time, poor operability, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

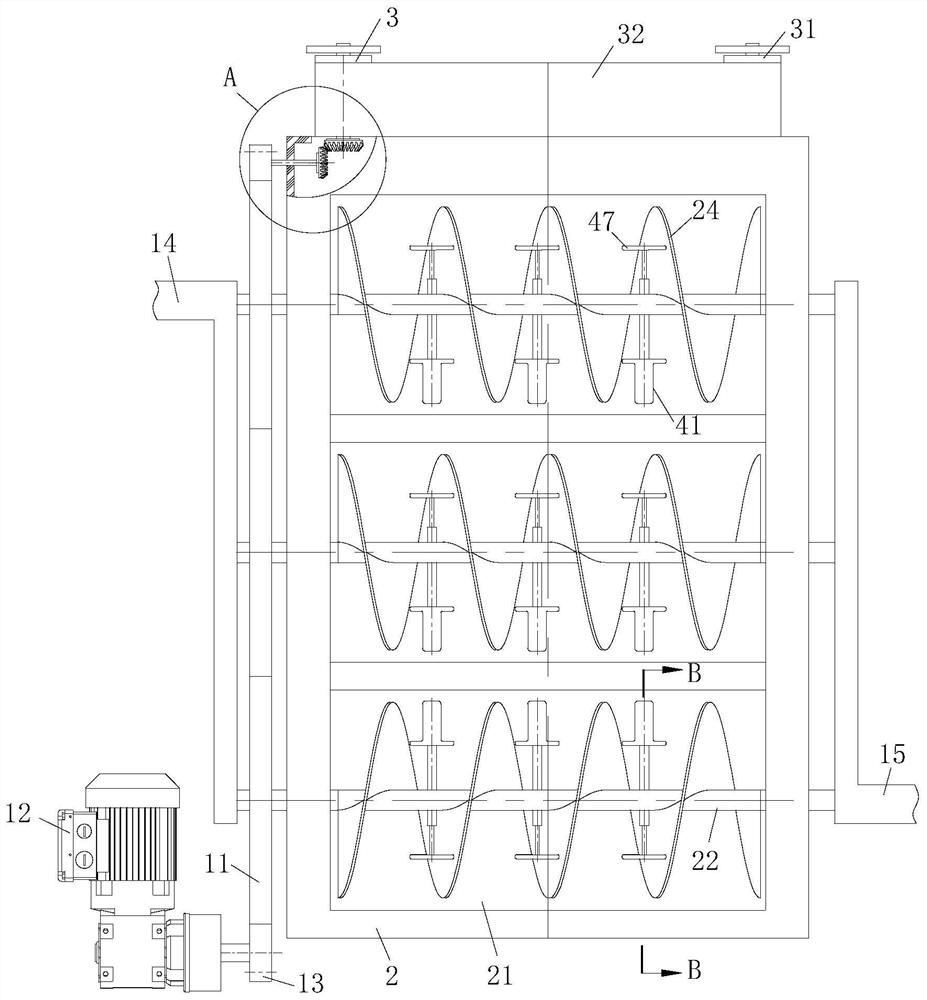

[0027] As an embodiment of the present invention, a group of ventilation holes 48 are uniformly opened on the inner wall of the sliding hole 43 and the corresponding position of the spring 44, and the diameter of the ventilation hole 48 gradually decreases from the inner wall of the sliding hole 43 to the outside; When sliding continuously in the sliding hole 43 in the sliding hole 43, compressed gas is generated in the sliding hole 43, and the compressed gas in the sliding hole 43 is sprayed into the sludge in the groove 21 through the air hole 48, forming air bubbles, and accelerating the volatilization of water in the sludge. Finally, the air bubbles escape into the air during the agitation process of the auger 24, which further accelerates the drying efficiency of the sludge; meanwhile, the air hole 48 whose diameter gradually decreases from the inner wall of the sliding hole 43 to the outside can reduce the sludge clogging. stomata48.

[0028] As an embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com