Multi-type roller automatic cleaning equipment

An automatic cleaning, multi-model technology, applied in the field of roller cleaning, can solve the problems of poor cleaning effect, the position of the roller brush cannot be moved and rotated arbitrarily, etc., to improve the cleaning effect and reduce the cleaning dead angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

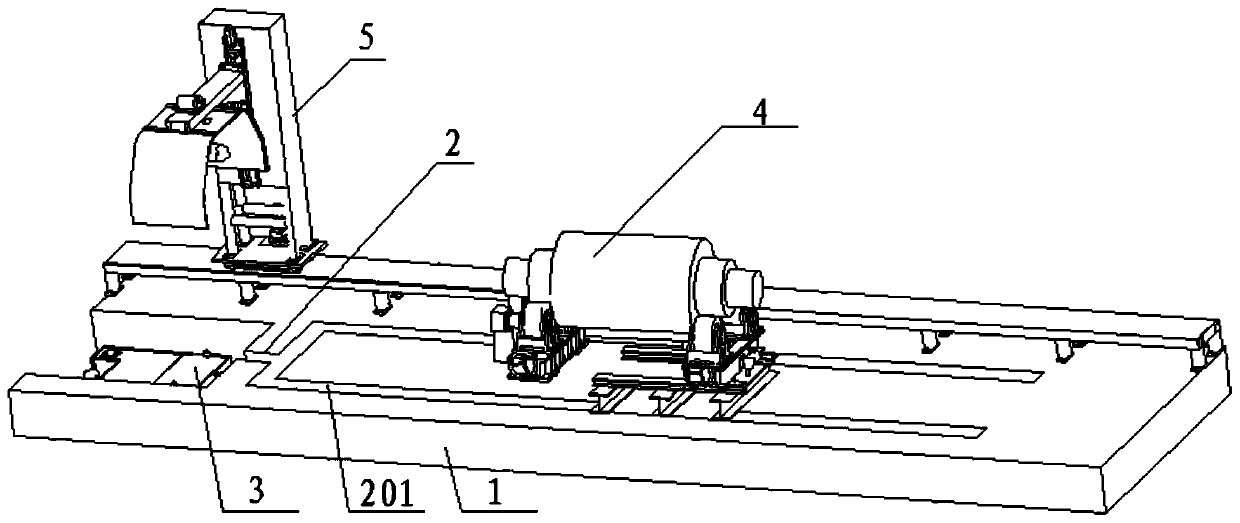

[0027] Such as Figure 1-6 As shown, a specific embodiment of a multi-type roll automatic cleaning equipment includes a base 1 and a recovery flow channel 2 opened on the base 1. The recovery flow channel 2 has two branches 201, and the two branches 201 are respectively located on both sides of the base 1, and the two branches 201 converge into the recovery device 3, and the rolls are cleaned on the base, and the cleaning liquid will converge into the two branches, and then flow into the recovery device from the branch of the recovery channel for recovery.

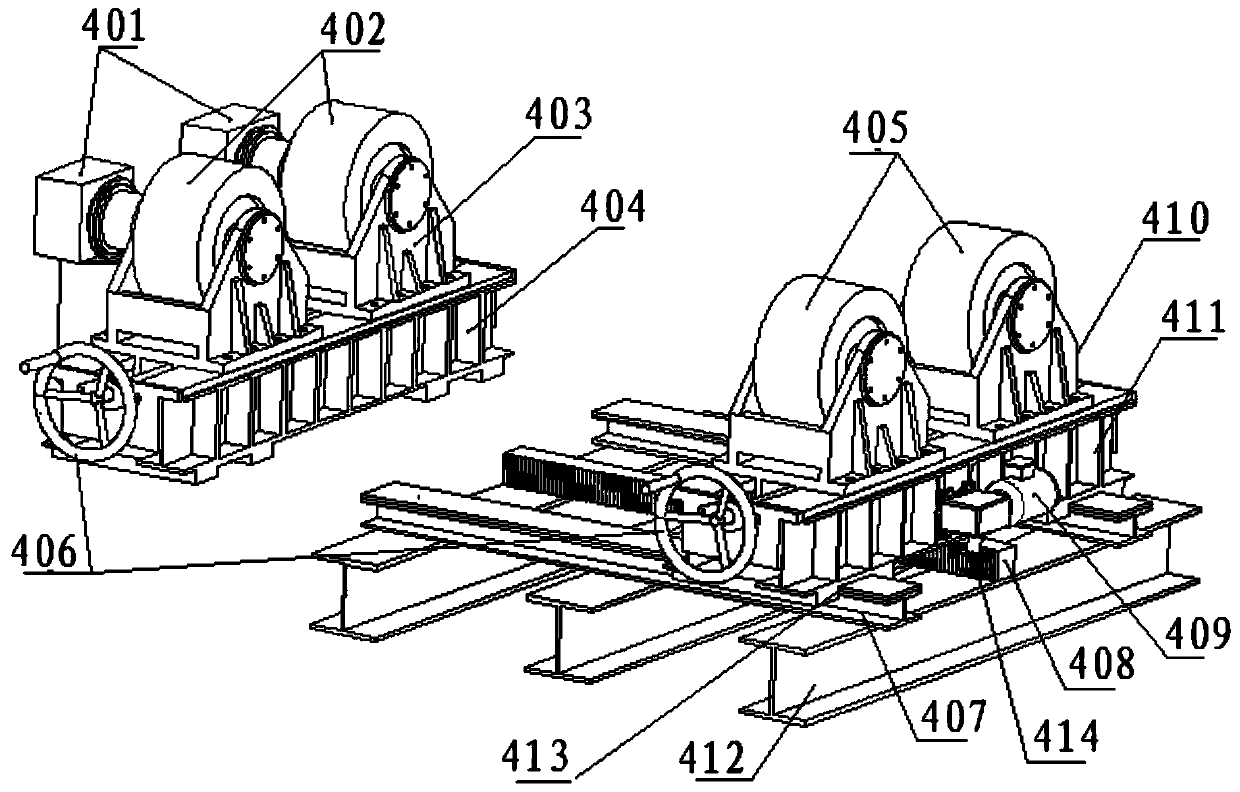

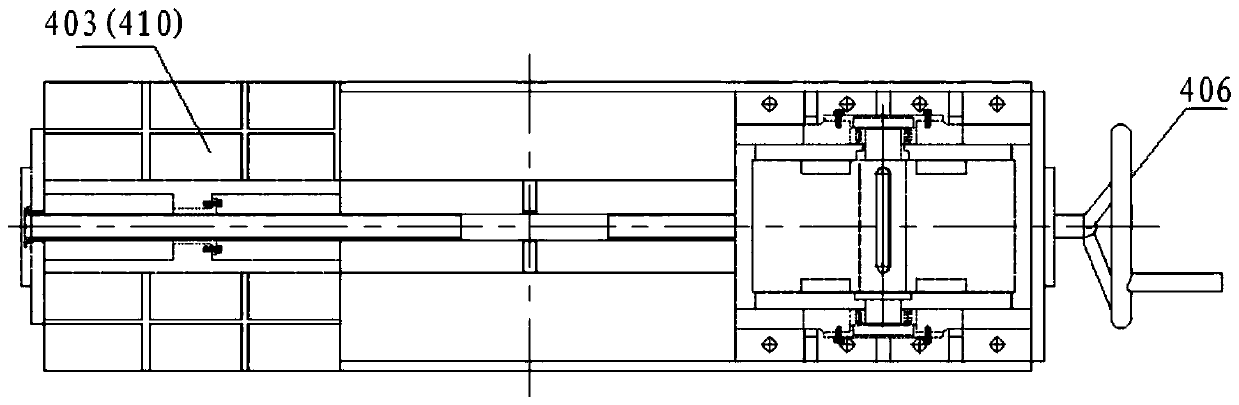

[0028] Such as figure 1 , 2As shown in . The base of the driven end is relatively arranged between the two branches, wherein the base of the driven end is formed by arranging three I-beams at intervals to facilitate the downward flow of cleaning liquid. A driven bracket 411 is movably installed on the driven end base 412, specifically, a guide rail 407 is welded and fixed on the upper end surface of the driven end base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com