Valganciclovir composition

A technology of valganciclovir and valganciclovir hydrochloride, applied in the pharmaceutical field, can solve the problems of poor tableting effect, inconvenient storage, poor absorption effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

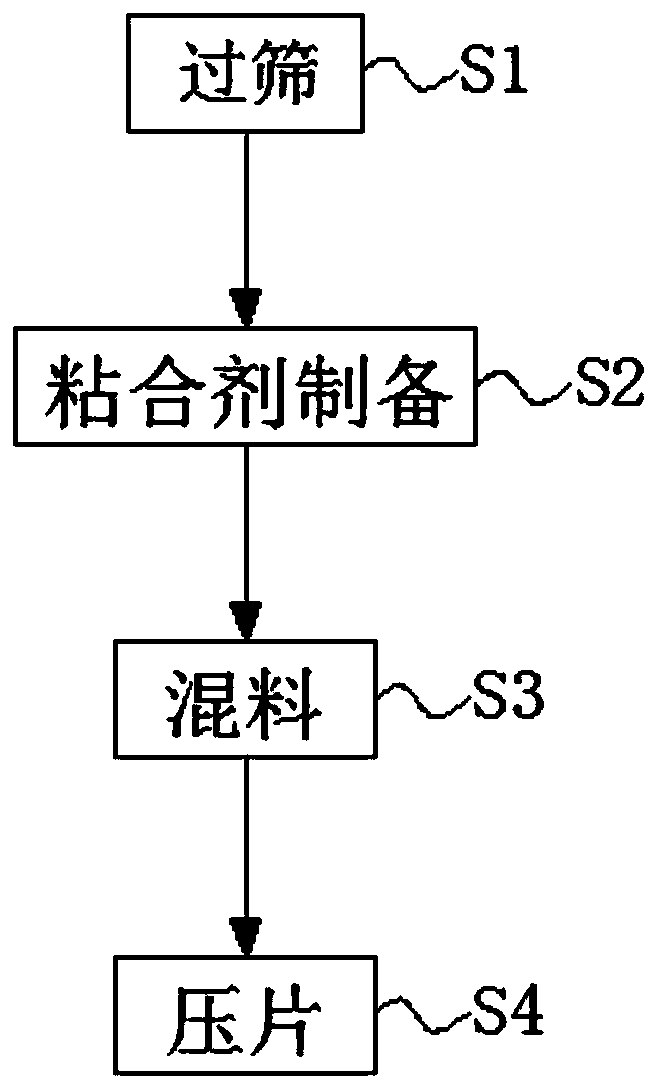

Method used

Image

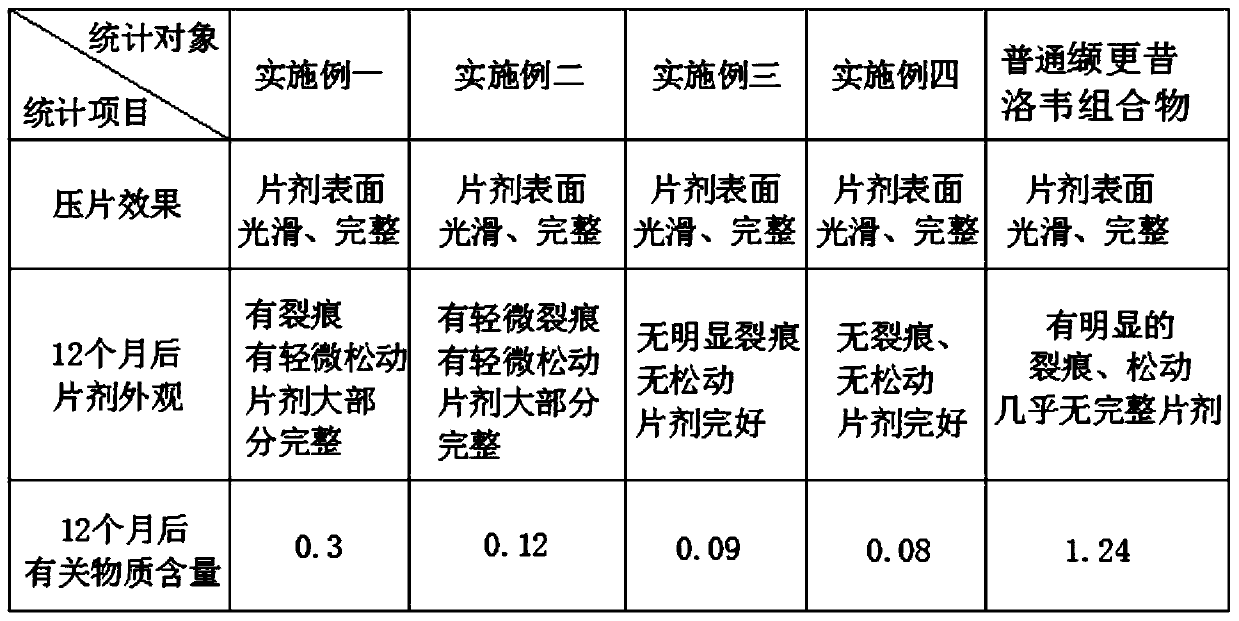

Examples

Embodiment 1

[0028] S1, sieving: pass valganciclovir hydrochloride through a 90-mesh sieve, and pass tomatine through a 120-mesh sieve;

[0029] S2. Adhesive preparation: Take an appropriate amount of cornstarch and put it into a mixer, then add an appropriate amount of cold water, stir at a speed of 600r / min to form a starch suspension, then heat it on a water bath at 85°C, and continue to stir to make a starch slurry as an adhesive Mixture spare;

[0030] S3, mixing: get 50 parts of sieved valganciclovir hydrochloride in S1 and put it into a blender, then add 3 parts of stabilizer, 15 parts of tomatine and 5 parts of filler, under normal temperature condition with 800r / Stir at a speed of 1 min for 5 min to mix the materials evenly, then add 3 parts of lactose, 2 parts of binder and 8 parts of sodium hydroxymethyl starch successively and continue stirring to obtain a material mixture, then add a wetting agent, and use a vacuum dryer at 30 Vacuum drying at ℃;

[0031] S4. Tablet compres...

Embodiment 2

[0033] S1, sieving: pass valganciclovir hydrochloride through a 93-mesh sieve, and pass tomatine through a 127-mesh sieve;

[0034] S2. Adhesive preparation: Take an appropriate amount of cornstarch and put it into a mixer, then add an appropriate amount of cold water, stir at a speed of 600r / min to form a starch suspension, then heat it on a water bath at 88°C, and continue to stir to make a starch slurry as an adhesive Mixture spare;

[0035] S3, mixing: get 60 parts of sieved valganciclovir hydrochloride in S1 and put it into a blender, then add 4 parts of stabilizer, 18 parts of tomatine and 6 parts of fillers, under normal temperature condition with 800r / Stir for 7 minutes at a speed of 1 min to mix the materials evenly, then add 4 parts of lactose, 3 parts of binder and 9 parts of sodium hydroxymethyl starch successively and continue stirring to obtain a material mixture, then add a wetting agent, and use a vacuum dryer to dry Vacuum drying at 30°C;

[0036]S4. Tablet...

Embodiment 3

[0038] S1, sieving: pass valganciclovir hydrochloride through a 98-mesh sieve, and pass tomatine through a 125-mesh sieve;

[0039] S2. Adhesive preparation: Take an appropriate amount of cornstarch and put it into a mixer, then add an appropriate amount of cold water, stir at a speed of 600r / min to form a starch suspension, then heat it on a water bath at 92°C, and continue stirring to make a starch slurry as a paste Mixture spare;

[0040] S3, mixing: get 70 parts of sieved valganciclovir hydrochloride in S1 and put it into a blender, then add 6 parts of stabilizers, 22 parts of tomatine and 7 parts of fillers, under normal temperature conditions with 800r / Stir at a speed of 8 min to mix the materials evenly, then add 5 parts of lactose, 4 parts of adhesives and 11 parts of sodium hydroxymethyl starch successively and continue stirring to obtain a material mixture, then add a wetting agent, and use a vacuum dryer to dry Vacuum drying at 30°C;

[0041] S4. Tablet compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com