ZrS2/III-V group semiconductor nanowire array heterojunction, preparation method thereof and application thereof

A III-V, nanowire array technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of insufficient light absorption and low photoelectric conversion efficiency, and achieve improved light absorption and photoelectric conversion Efficiency, the effect of realizing wide-angle absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

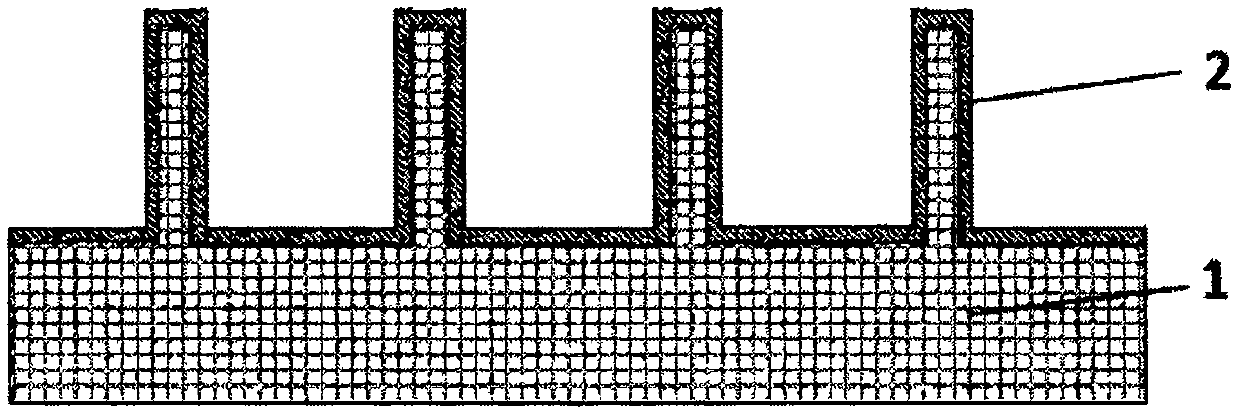

[0021] a ZrS 2 / GaN nanowire array heterogeneous, junction reference figure 1 , the invention comprises a layer of n-type doped GaN substrate, GaN nanowires with an array structure are vertically grown on the GaN substrate, and continuous ZrS is deposited on the surface of the GaN substrate and the GaN nanowire array structure 2 film. In this embodiment, the thickness of the 2-inch GaN substrate is 200 μm, and the carrier concentration is 5×10 16 cm -3 ; The GaN nanowire diameter is 200nm, the height is 3μm, and the period of the GaN nanowire array is 0.5μm. ZrS deposited by atomic layer deposition process 2 The thickness of the film is 2.4nm, and the ZrS 2 The thin film uniformly spreads on the surface of the GaN substrate and the GaN nanowire array.

[0022] The preparation method of the heterojunction in this embodiment is as follows:

[0023] 1) Ultrasonic cleaning of the GaN substrate with alcohol, acetone, and deionized water;

[0024] 2) Using epitaxy to grow Ga...

Embodiment 2

[0028] a ZrS 2 / InAs nanowire array heterogeneous, junction reference figure 1 , the present invention comprises a layer of n-type doped InAs substrate, InAs nanowires of array structure are vertically grown on the InAs substrate, continuous ZrS is deposited on the surface of InAs substrate and InAs nanowire array structure 2 film. In this embodiment, the thickness of the 2-inch InAs substrate is 300 μm, and the carrier concentration is 3×10 18 cm -3 ; The diameter of the InAs nanowire is 500nm, the height is 10μm, and the period of the InAs nanowire array is 2μm. ZrS deposited by atomic layer deposition process 2 The thickness of the film is 6nm, and the ZrS 2 The film evenly covers the InAs substrate and the surface of the InAs nanowire array.

[0029] The preparation method of the heterojunction in this embodiment is as follows:

[0030] 1) Ultrasonic cleaning of the InAs substrate with alcohol, acetone, and deionized water;

[0031] 2) growing InAs nanowire arrays ...

Embodiment 3

[0035] a ZrS 2 / GaAs nanowire array heterogeneous, junction reference figure 1 , the present invention comprises a layer of n-type doped GaAs substrate, GaAs nanowires with an array structure are vertically grown on the GaAs substrate, and continuous ZrS is deposited on the surface of the GaAs substrate and the GaAs nanowire array structure 2 film. In this embodiment, the thickness of the 2-inch GaAs substrate is 350 μm, and the carrier concentration is 7×10 17 cm -3 ; The GaAs nanowire diameter is 500nm, the height is 50μm, and the period of the GaAs nanowire array is 5μm. ZrS deposited by atomic layer deposition process 2 The thickness of the film is 36nm, and the ZrS 2 The thin film uniformly spreads on the surface of the GaAs substrate and the GaAs nanowire array.

[0036] The preparation method of the heterojunction in this embodiment is as follows:

[0037] 1) Ultrasonic cleaning of the GaAs substrate with alcohol, acetone, and deionized water;

[0038] 2) GaAs n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com