Zirconium disulfide-germanium nano-pyramid heterojunction, preparation method and application thereof

A technology of zirconium disulfide and pyramid structure, which is applied in the manufacture of final products, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of insufficient light absorption and low photoelectric conversion efficiency, and achieves improved light absorption and photoelectric conversion efficiency. , to achieve the effect of wide-angle absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

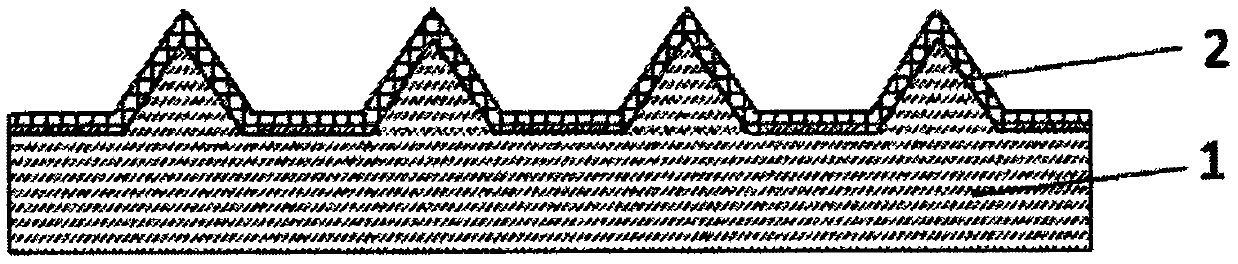

[0021] refer to figure 1 , the invention includes a layer of germanium substrate, and the zirconium disulfide thin film is arranged on the germanium substrate. In this embodiment, the germanium substrate adopts a 1×1cm substrate with a thickness of 150 μm 2 single-sided polished single-crystal germanium sheet, the conductivity type is n-type, and the resistivity is 0.05Ωcm; the polished surface of the germanium substrate is etched by an anisotropic etching method to etch a pyramid structure with a quadrilateral base, and the side length of the quadrilateral base is is 0.5 μm, the height of the pyramid structure is 0.5 μm, and the density of the nano-pyramids on the surface of the germanium sheet is 4×10 8 cm -2 . In this embodiment, the zirconium disulfide film evenly covers the surface of the germanium substrate and the sidewalls of the nano-pyramids, and the thickness of the zirconium disulfide film is 12 nm.

[0022] The preparation steps of the heterojunction in this e...

Embodiment 2

[0029] refer to figure 1 , the invention includes a layer of germanium substrate, and the zirconium disulfide thin film is arranged on the germanium substrate. In this embodiment, the germanium substrate adopts a 2×1cm substrate with a thickness of 150 μm 2 A single-sided polished single-crystal germanium wafer, the conductivity type is n-type, and the resistivity is 0.2Ωcm; the polished surface of the germanium substrate is etched by an anisotropic etching method to etch a pyramid structure with a quadrilateral base, and the side length of the quadrilateral base is is 2 μm, the height of the pyramid structure is 2 μm, and the density of the nano-pyramids on the surface of the germanium sheet is 4×10 7 cm -2 . In this embodiment, the zirconium disulfide film evenly covers the surface of the germanium substrate and the side walls of the nano-pyramids, and the thickness of the zirconium disulfide film is 48 nm.

[0030] The preparation steps of the heterojunction in this emb...

Embodiment 3

[0037] refer to figure 1 , the invention includes a layer of germanium substrate, and the zirconium disulfide thin film is arranged on the germanium substrate. In this embodiment, the germanium substrate adopts a 2×2cm substrate with a thickness of 200 μm 2 single-sided polished single-crystal germanium sheet, the conductivity type is n-type, and the resistivity is 0.25Ωcm; the polished surface of the germanium substrate is etched by an anisotropic etching method to etch a pyramid structure with a quadrilateral base, and the side length of the quadrilateral base is is 5 μm, the height of the pyramid structure is 5 μm, and the density of the nano-pyramids on the surface of the germanium sheet is 4×10 6 cm -2 . In this embodiment, the zirconium disulfide film uniformly covers the surface of the germanium substrate and the side walls of the nano-pyramids, and the thickness of the zirconium disulfide film is 60 nm.

[0038] The preparation steps of the heterojunction in this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com