Tire electronic tag production device and method thereof

An electronic label and production device technology, applied in the directions of antenna supports/installation devices, circuits, electrical components, etc., can solve the problems of difficulty in meeting the mass production of tire electronic labels, low product yield, and a large number of manual assistance, and achieve sliding work. The effect of stable, small impact and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

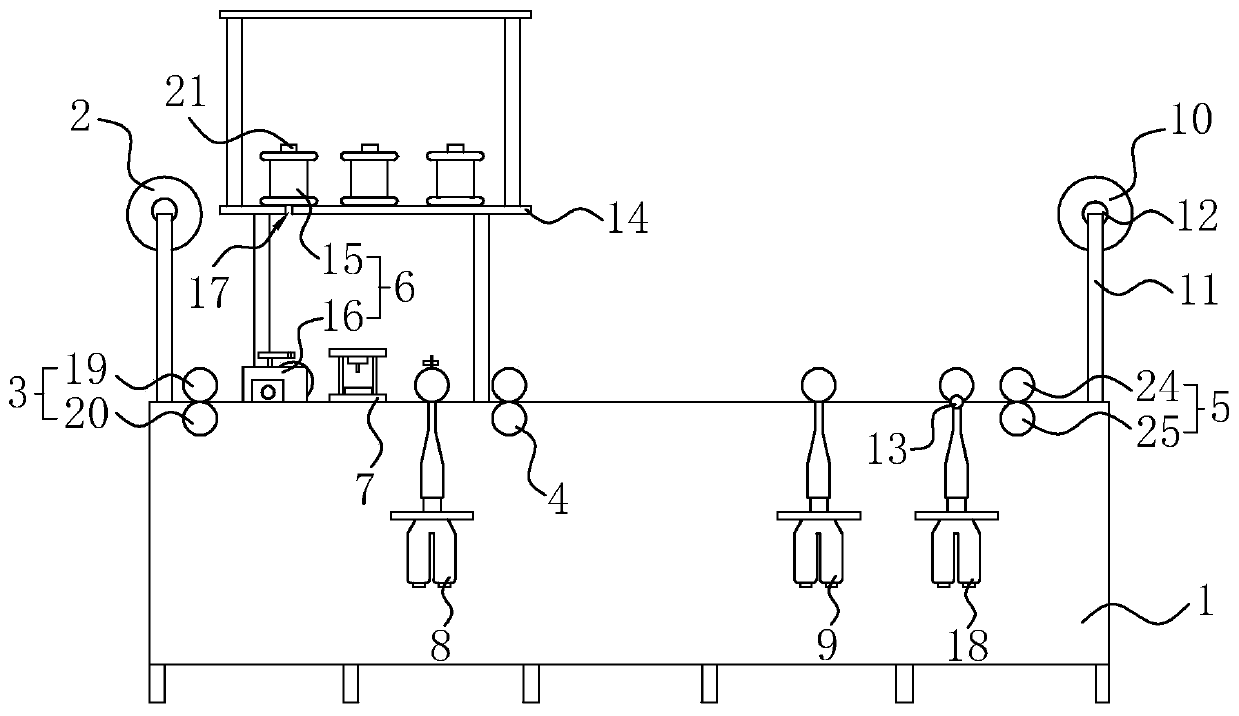

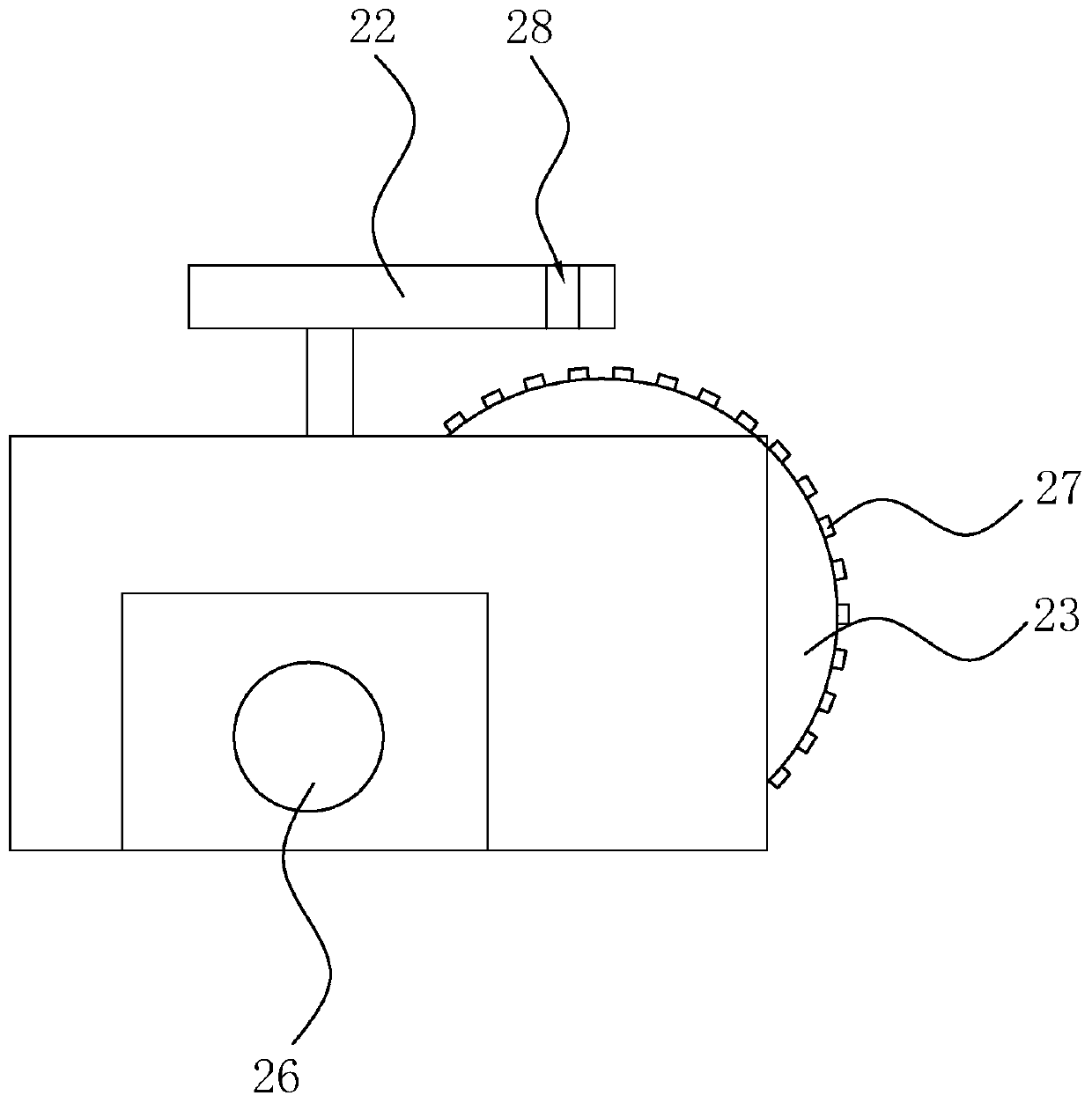

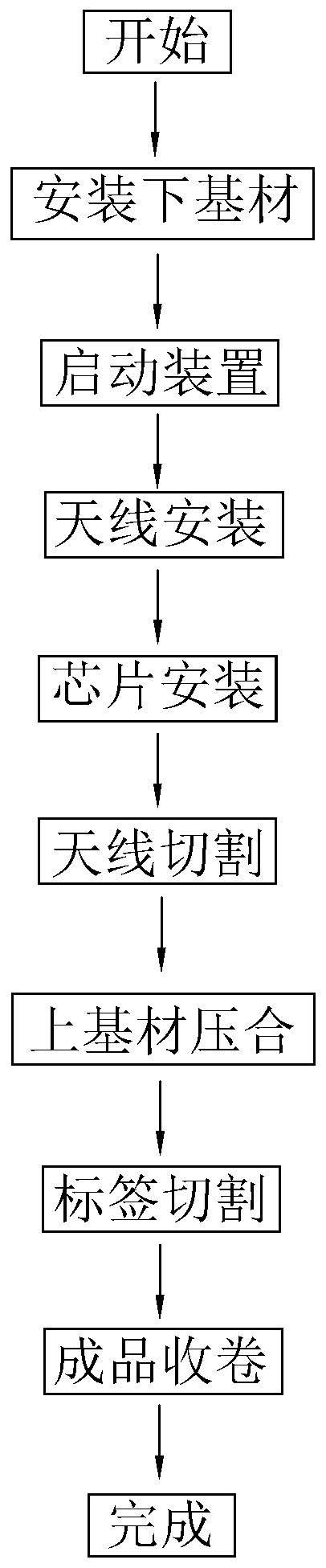

[0044] Such as figure 1 As shown, an electronic label production device for tires includes a rectangular workbench 1 for supporting the device away from the ground. The workbench 1 is equipped with a feeding mechanism 2, a conveying mechanism, antenna mounting mechanism 6, chip mounting mechanism 7, cutting mechanism, pressing mechanism 9, and material receiving mechanism 10. Concretely, the workbench 1 is provided with a support frame 11 perpendicular to the workbench 1 in the shape of "冂" along the length direction of the workbench 1, and the feeding mechanism 2 and the receiving mechanism 10 are respectively arranged on the sides of the workbench 1. on the support frame 11. Wherein, the receiving mechanism 10 includes a rotating shaft 12 and a first driving device (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com