Automatic equipment for vessel filling

A technology of automation equipment and utensils, which is applied in the directions of automatic packaging control, packaging, packaging protection, etc., and can solve the problems of low degree of automation, large space occupied by equipment, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

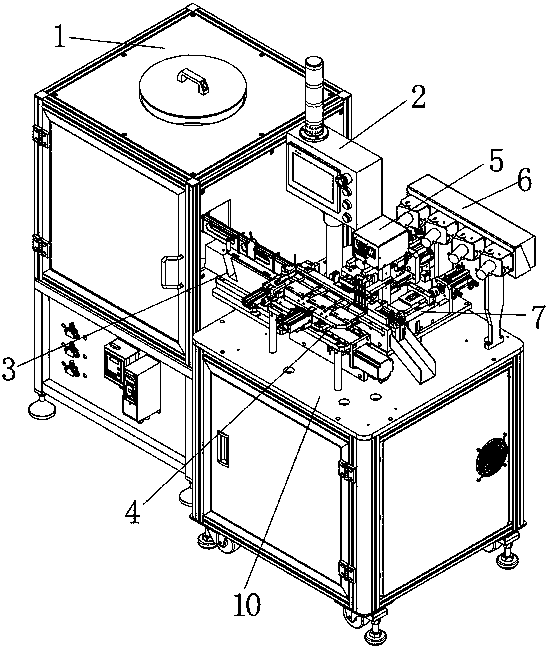

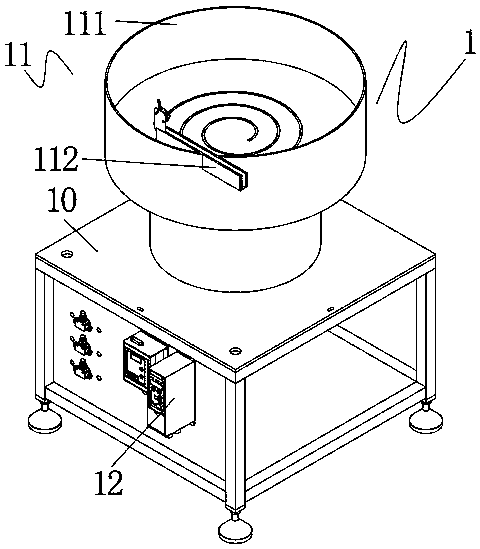

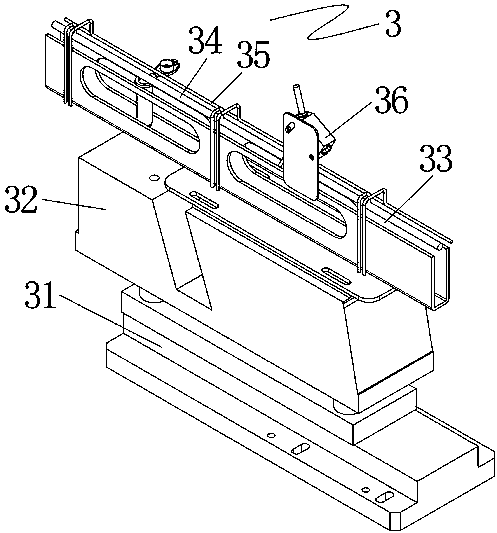

[0031] Reference attached figure 1 , an automatic equipment for container filling, including a frame 10, on which a feeding device 1, a touch screen 2, a conveying device 3, a separation and transfer device 4, a heat sealing device 5, a liquid injection device 6 and a buckle The capping device 7 and the conveying device 3 are arranged between the feeding device 1 and the separation and transfer device 4, the heat sealing device 5, the liquid injection device 6 and the capping device 7 are all arranged on the same side of the separation and transfer device 4, and the feeding device 1 Transport the containers to the conveying device 3. After the conveying device 3 transports the containers to the separation and transfer device 4, the separation and transfer device 4 transports a certain number of containers in batches to the heat sealing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com