Tape lapping head aerial attitude position change method and device

A perverted and attitude technology, applied in the field of motor coil manufacturing and processing, can solve the problems of reducing the space height of the tape head, difficult to guarantee repeatability, inconvenient adjustment and operation, etc., to reduce the teaching time, compact structure, and stable and reliable adjustment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

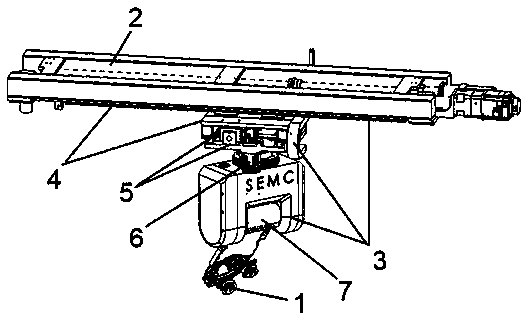

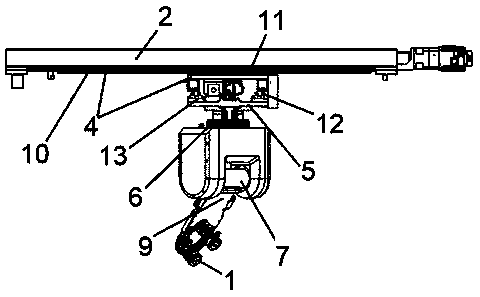

[0035]by attaching Figure 1-5 It can be seen that the present invention relates to a taping head attitude position abnormal device in the air, including a taping head 1, the taping head 1 is hoisted under the beam 2 of the frame, and the taping head is hoisted on the beam 2 of the frame through a four-axis linkage assembly 3 Next, the attitude change of the taping head in the air is realized through the mutual cooperation of the four-axis linkage assembly 3 .

[0036] Further, the four-axis linkage assembly 2 includes a moving assembly 4 along the X axis, a moving assembly 5 along the Y axis, a Z-axis rotating assembly 6 rotating around the Z axis, and a Y-axis rotating assembly 7 rotating around the Y axis; The installation sequence of the above-mentioned four-axis linkage component 3 hoisting under the beam 2 is that the moving component along the X axis moving left and right along the X axis is on the uppermost layer, on the same level as the beam 2, and the moving compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com