Continuous multi-station battery core winding device

A winding device and multi-station technology, applied in the field of continuous multi-station cell winding device, can solve the problems of high production efficiency and production cost reduction, reduce noise, improve production efficiency, and save changing stations effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

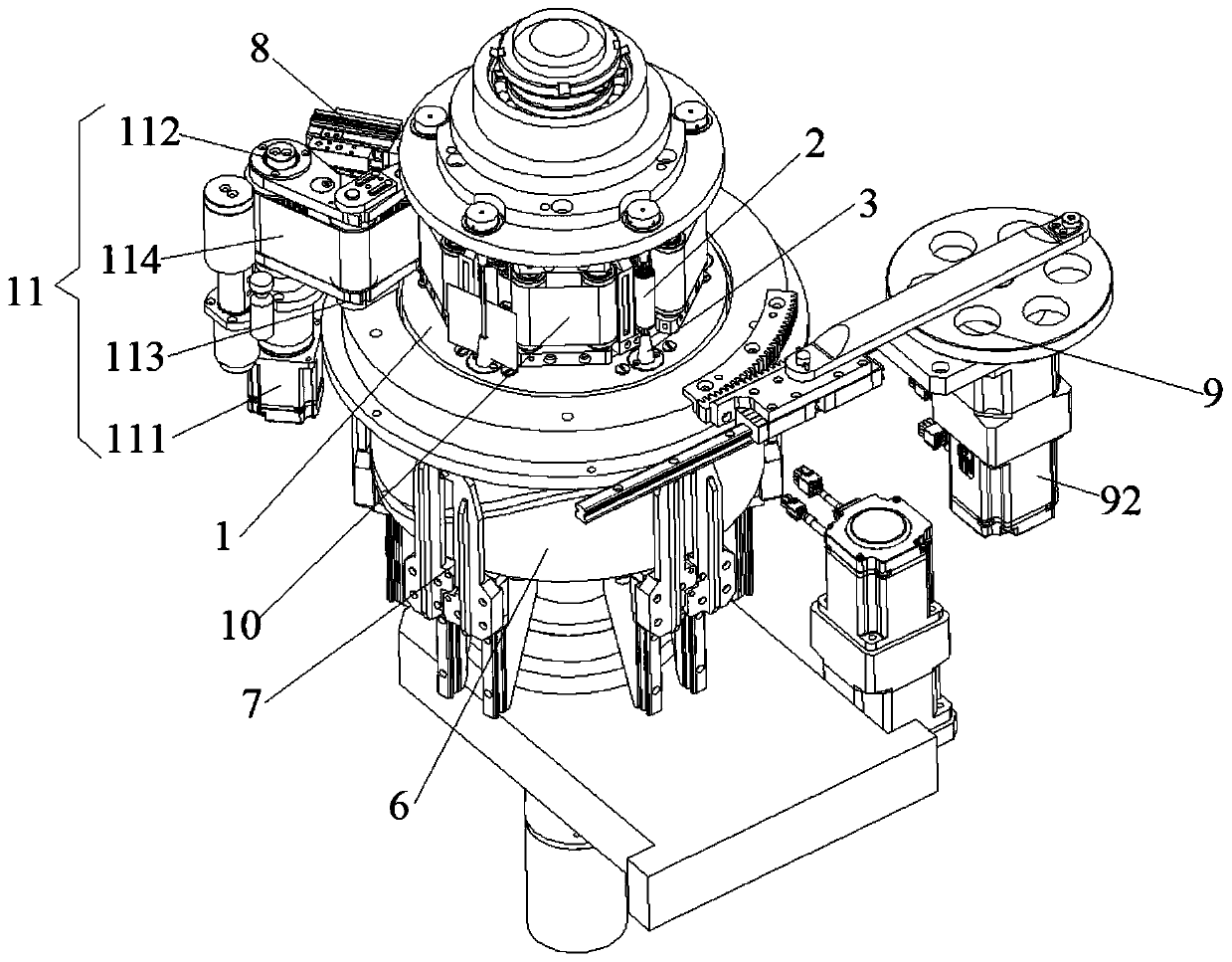

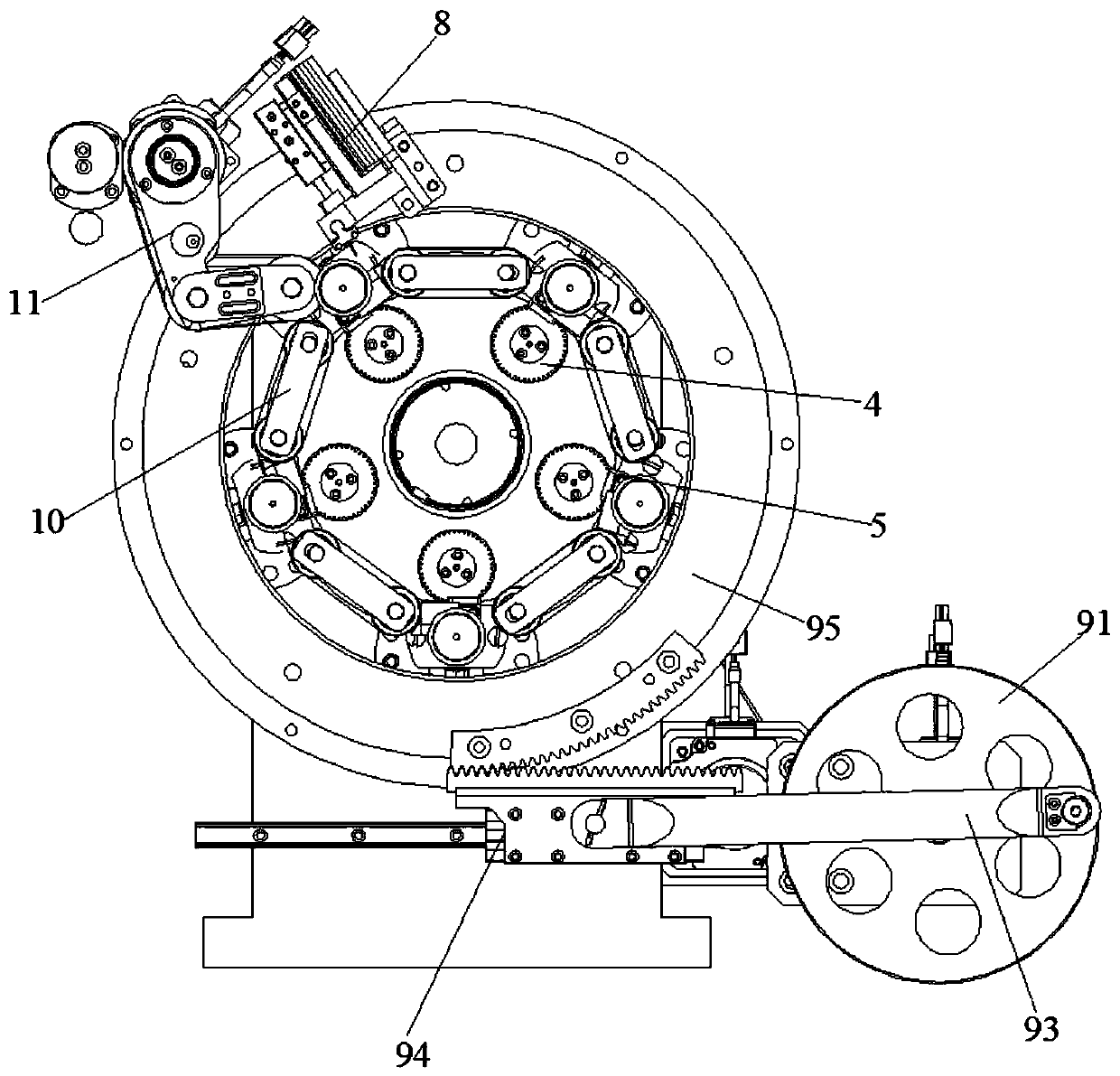

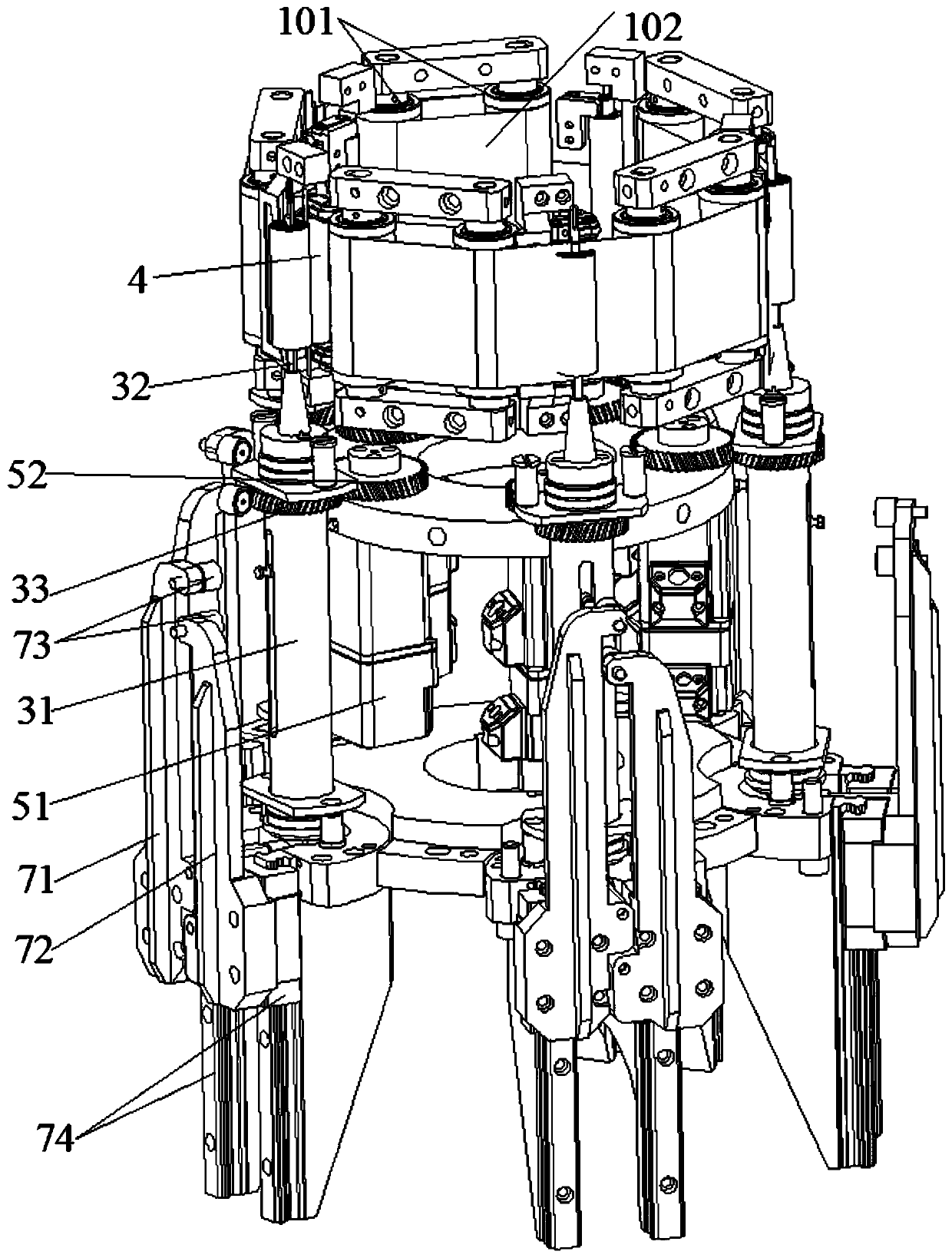

[0021] A continuous multi-station cell winding device proposed in this embodiment, refer to Figure 1 to Figure 5 , comprising a rotor 1, on which a plurality of syringe assemblies 3 for winding the tape 2 are evenly distributed along the circumference of the rotor 1, and any of the syringe assemblies 3 is correspondingly provided with one for pressing the tape 2 on the The elastic pressing material assembly 4 on the syringe assembly 3; any of the syringe assemblies 3 is connected with a rotary drive assembly 5 for driving its rotation, and the syringe assembly 3 includes a guide cylinder 31, and the guide cylinder 31 Two roll needles 32 are slidably installed inside along its length direction, and a gap for the strip material 2 to pass is provided between the two roll needles 32; a cylindrical tube 6 is also coaxially sleeved on the outer surface of the rotor 1, so that The outer surface of the cylinder 6 is provided with a plurality of lifting drive assemblies 7 for driving ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap