Mechanical overload switch for external ballistic trajectory data acquisition system

A technology of data acquisition system and overload switch, which is applied in the direction of electric switch, ammunition test, ammunition, etc. It can solve the problems of short connection time between moving contact and static contact, inability to guarantee power supply circuit, spring deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

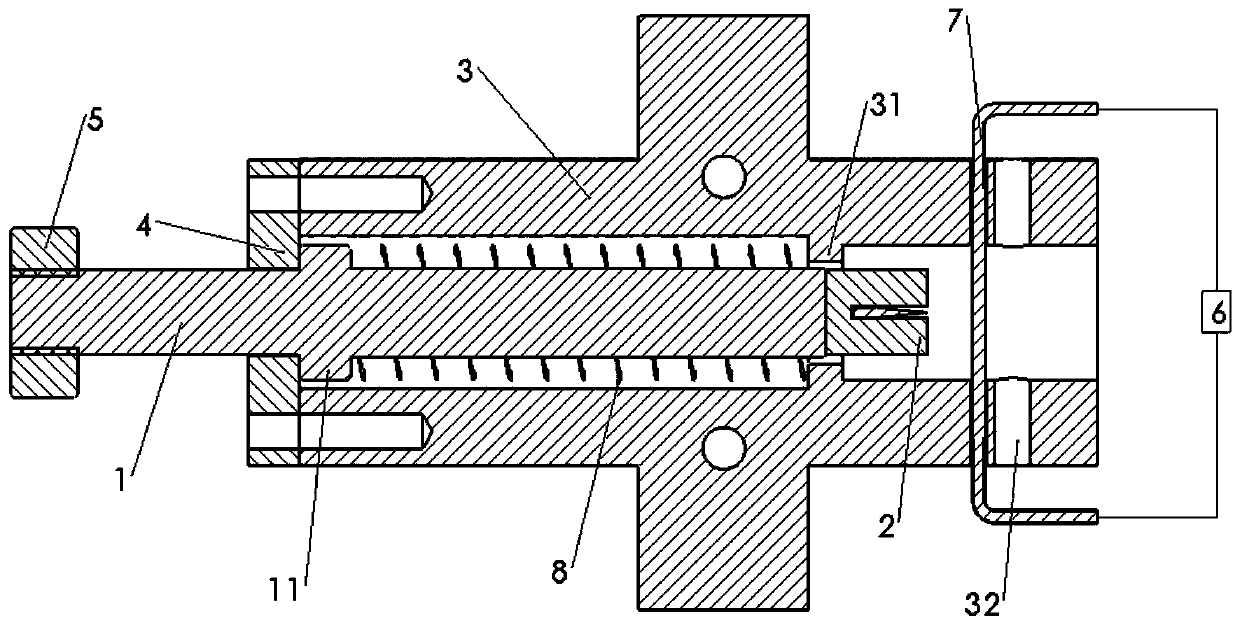

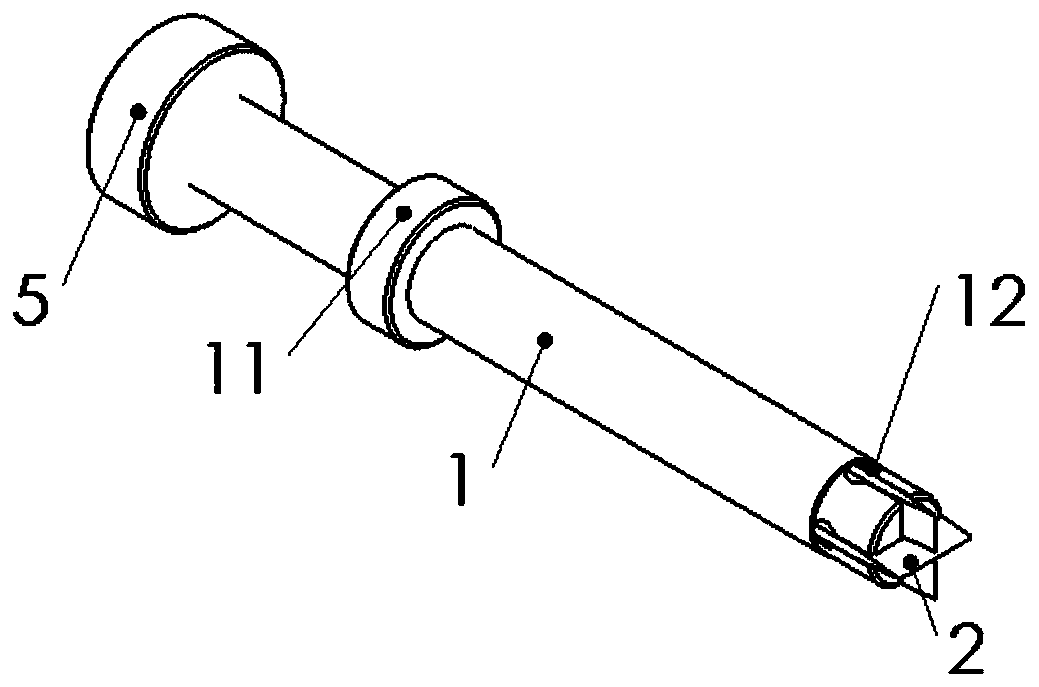

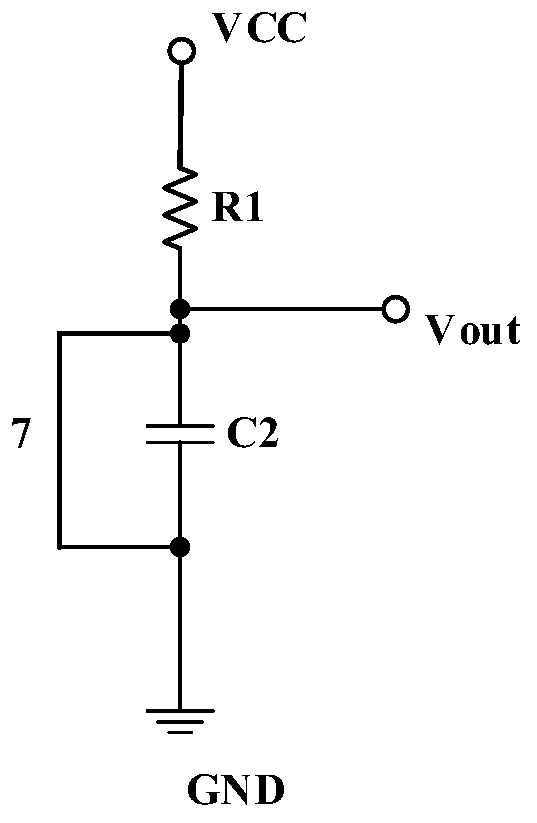

[0017] A mechanical overload switch for an external ballistic data acquisition system of the present invention includes an excitation component, a switch housing 3, a housing cover 4, a return spring 8, a delay circuit 6, and a wire 7; the excitation component includes a mass block 5 , trigger rod 1, contact 2; the trigger rod 1 is a cylindrical structure with a shoulder 11 in the middle of the cylinder for supporting one end of the return spring 8; a ring of bosses 31 are provided in the switch housing 3 for Support the other end of the return spring 8; one end of the excitation rod 1 is located inside the switch housing 3, and the other end is located outside the switch housing 3, the switch housing 3 is provided with a housing cover 4, and the activation rod 1 passes through the housing cover 4, The housing cover 4 axially locates the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com