Electric wire embossing device

A technology of patterns and wires, applied in circuits, used to form corrugations on conductors/cables, electrical components, etc., can solve problems such as slippage, improve wire cooling, improve embossing effect, improve efficiency and embossing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

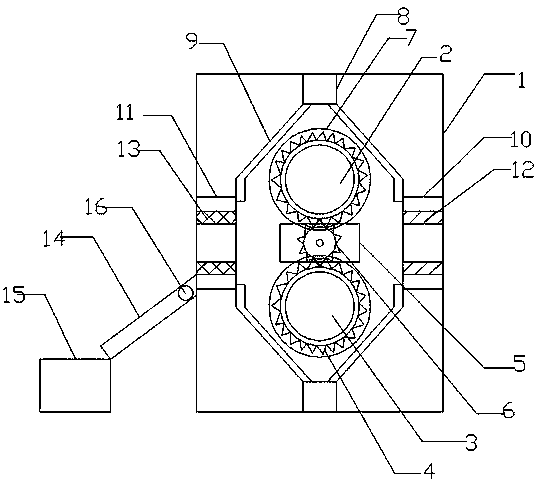

[0013] Such as figure 1 As shown, the present embodiment provides a wire embossing device, including a frame 1, the upper and lower sides of the middle of the frame 1 are symmetrically provided with an upper roller 2 and a lower roller 3, and the front ends of the upper roller 2 and the lower roller 3 are both Connected with a rotating gear 4, the front side of the frame 1 is provided with a driving motor 5, and the output end of the driving motor 5 is connected with an interlocking gear 6, and the interlocking gear 6 is meshed and connected between the upper and lower rotating gears 4, and the upper roller 2 and the lower roller The surface of the rotating roller 3 is provided with an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com