Production dispatching method and system of distributed hybrid flow shop

A production scheduling and workshop scheduling technology, applied in control/regulation systems, general control systems, instruments, etc., can solve problems such as less research on distributed hybrid workshop scheduling problems, increase the probability of finding a better solution, improve The effect of population quantity and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

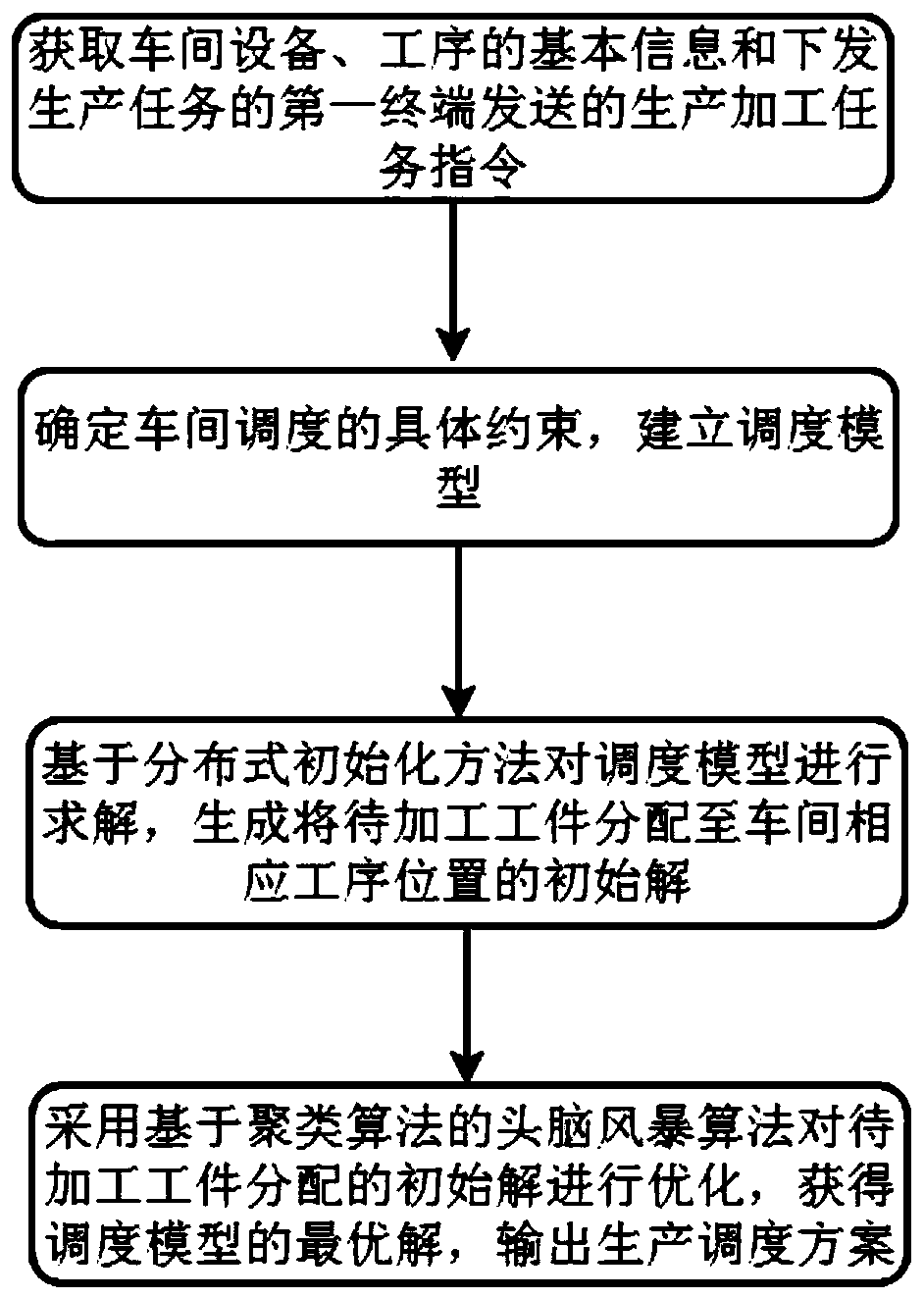

[0035] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, a production scheduling method for a distributed mixed flow workshop includes the following steps:

[0036] Step 1. Obtain the basic information of the workshop equipment and process and the production and processing task instruction sent by the first terminal that issues the production task; the production and processing instruction includes the workpiece and the quantity to be processed;

[0037] Step 2. Determine the specific constraints of workshop scheduling and establish a scheduling model;

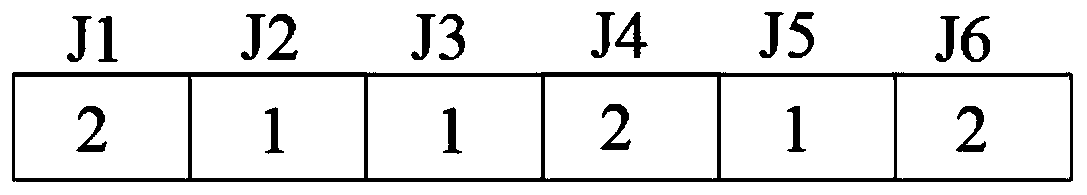

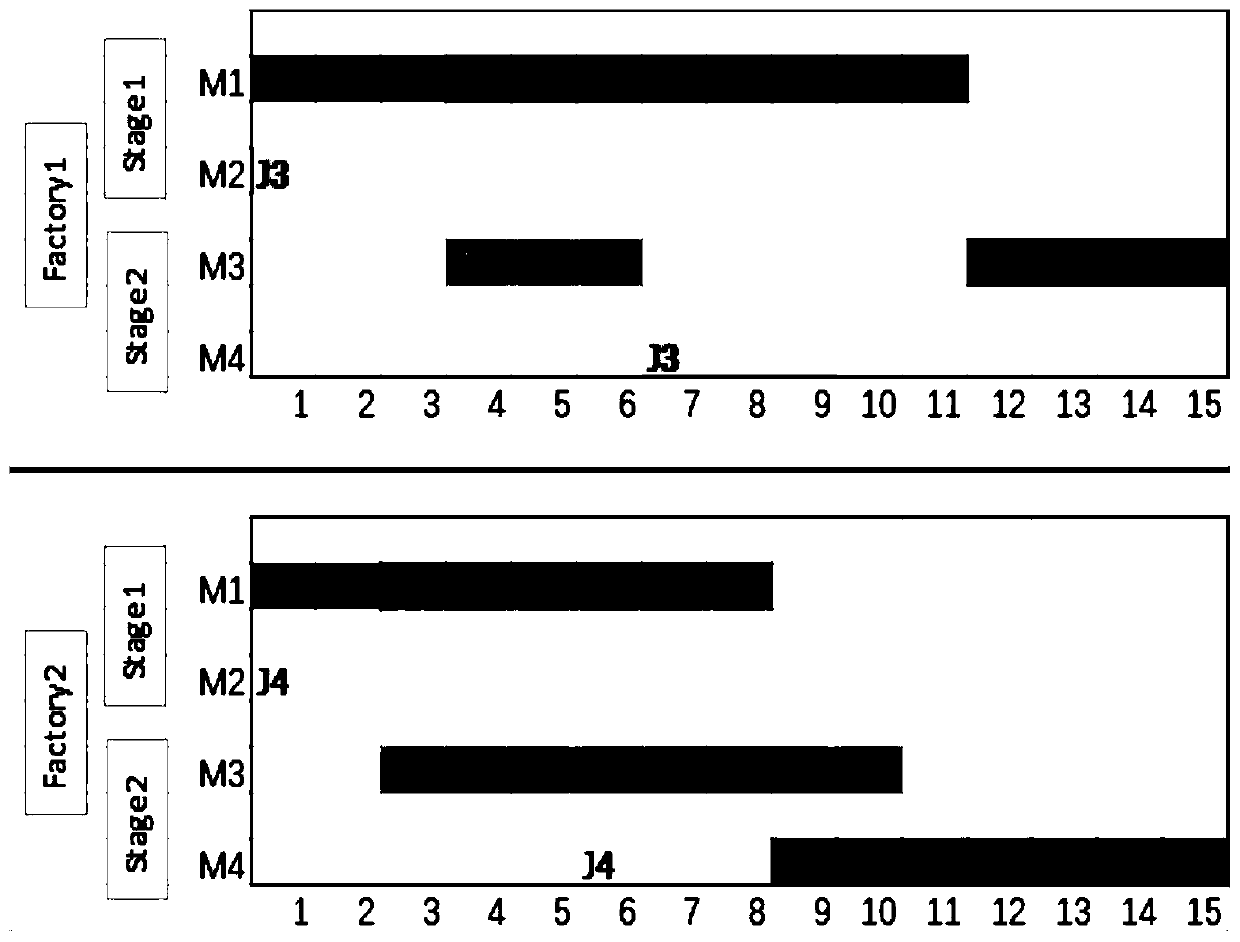

[0038] Step 3. Solve the scheduling model based on the distributed initialization method, and generate an initial solution for assigning the workpieces to be processed to the corresponding process positions in the workshop;

[0039] Step 4: Optimizing the initial solution of the allocation of workpieces to be processed by using the brainstorming algorithm based on the clustering algor...

Embodiment 2

[0136] This embodiment provides a production scheduling system for a distributed mixed flow workshop, including:

[0137] Production task receiving module: used to obtain the basic information of workshop equipment and procedures and the production and processing task instructions sent by the first terminal for issuing production tasks; the production and processing instructions include the workpieces to be processed, the quantity and the required completion time;

[0138] Scheduling model building module: used to determine the specific constraints of workshop scheduling and establish a scheduling model;

[0139] Initialization solution module: used to solve the scheduling model based on the distributed initialization method, and generate an initial solution for assigning the workpieces to be processed to the corresponding process positions in the workshop;

[0140] Optimization output module: It is used to optimize the initial solution of the allocation of workpieces to be pr...

Embodiment 3

[0142] This embodiment provides an electronic device, including a memory, a processor, and computer instructions stored in the memory and run on the processor. When the computer instructions are executed by the processor, the steps described in Embodiment 1 are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com