A simulation experiment method and experimental device for fracturing proppant transportation with real-time variable sand ratio

A technology of fracturing proppant and simulation experiment, which is applied in the field of fracturing reconstruction of oil and gas wells and coalbed methane wells, and can solve the problems of not being able to realize real-time, changing sand ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

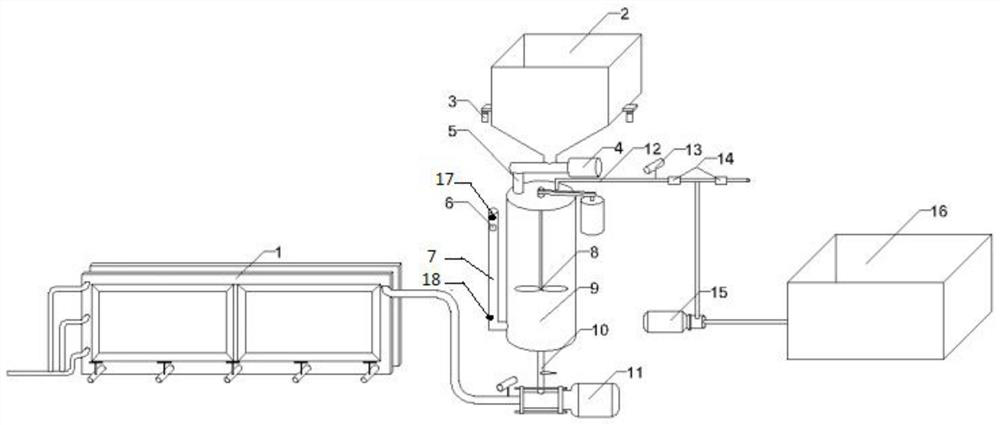

[0040] like figure 1 As shown, the fracturing proppant delivery simulation experiment device for real-time variable sand ratio of the present invention includes a simulated crack 1, a sand mixing cylinder 9 connected to the simulated crack, a sand inlet system connected to the sand inlet 5 of the sand mixing cylinder, A liquid inlet system connected to the liquid inlet 12 of the sand mixing cylinder.

[0041] The sand feeding system includes a sand storage hopper 2, and a load cell 3 is installed on each of the front, rear, left, and right side walls of the sand storage hopper, which can weigh and record the change of proppant quality. Four weighing sensors measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com