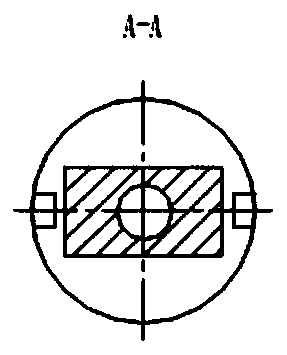

Four-component tubular wind tunnel balance with transverse jet

A wind tunnel balance, four-component technology, applied in measurement devices, instruments, aerodynamic tests, etc., can solve the problem that the temperature effect of the balance is large, the influence of the balance measurement of the jet medium gas pipeline cannot be eliminated, and the measurement accuracy is difficult to meet. Indicator requirements and other issues, to achieve the effect of small size, reduced deformation, and increased output signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This example figure 2 As shown, the present embodiment is a separate use method of the horizontal jet four-component tube wind tunnel balance of the present invention and the test model. In this embodiment, the test model is designed and processed separately, and the mounting cone hole of the test model is matched with the mounting cone in front of the balance. The wind tunnel balance of this embodiment is applicable to multiple test models and has versatility. However, the jet flow chamber is located in the balance cone, limited by the structure of the model and the balance, the jet flow chamber cannot be very large; in addition, the air hole on the balance cone must be accurately matched with the nozzle inlet of the model and the sealing performance is good, which gives the model Machining places high demands.

Embodiment 2

[0023] This example Figure 6 As shown, this embodiment is an integrated use mode of the balance and the test model of the horizontal jet four-component tube wind tunnel balance of the present invention. In this embodiment, the integrated design and processing of the nozzle section of the test model and the balance, that is, the nozzle section of the test model is the balance head 8 . The advantage of this method is that there is no sealing problem of jet high-pressure gas, and the jet chamber can be made relatively large, but the balance has no versatility.

[0024] These two methods can well avoid the influence of the gas supply system on the balance measurement, and can be widely used in the wind tunnel test of the horizontal jet flow of the slender spiral body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com