Multi-element sensor embedding and protecting method for gathering pipeline monitoring

A technology for gathering and transportation pipelines and sensors, which is applied in the field of multi-sensor embedding and protection, can solve the problems of easy mutual interference between sensors and lines, lack of protection, and simple installation, and achieve convenient and quick assembly and use, good fixing effect, and high installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A multi-sensor embedding and protection method for gathering and transportation pipeline monitoring, comprising the following steps:

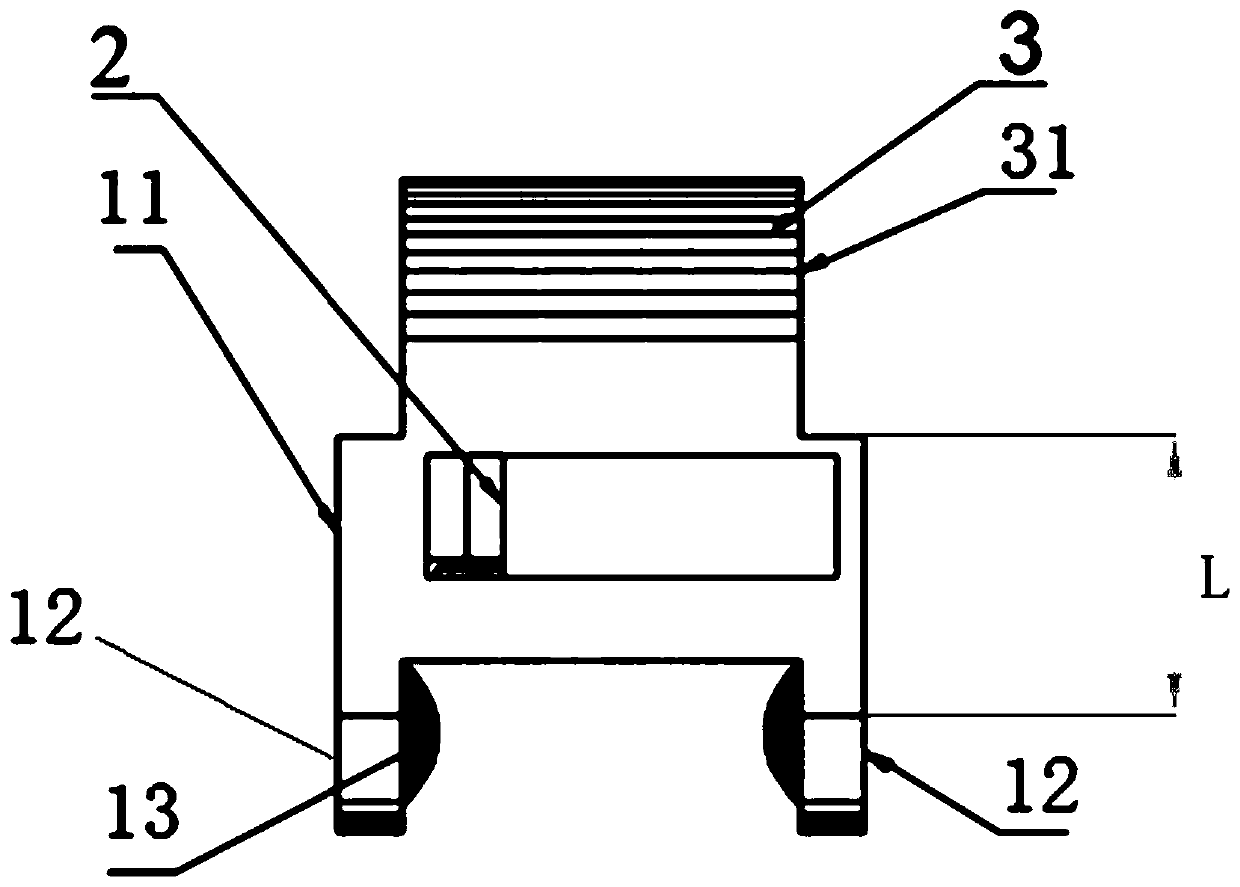

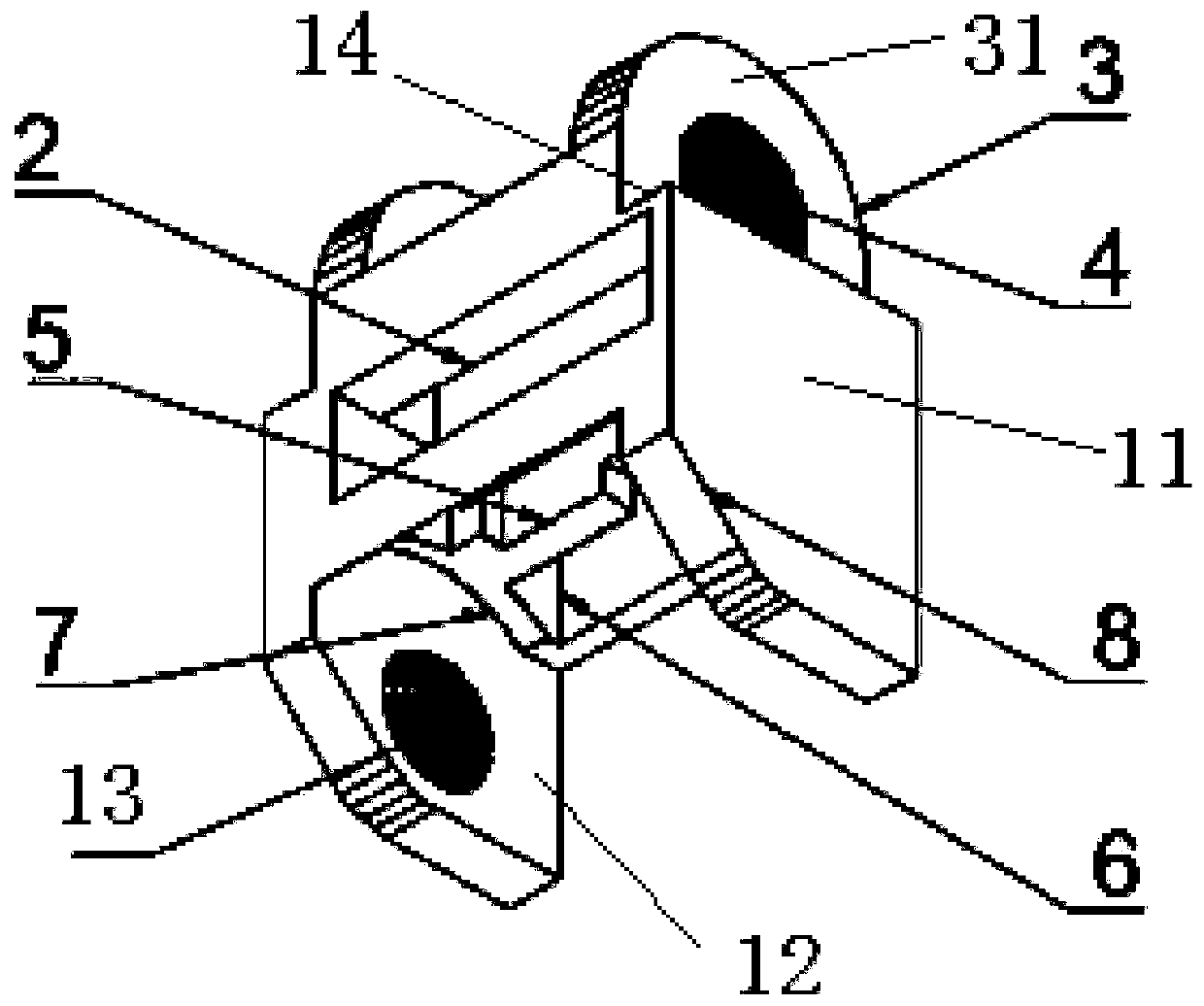

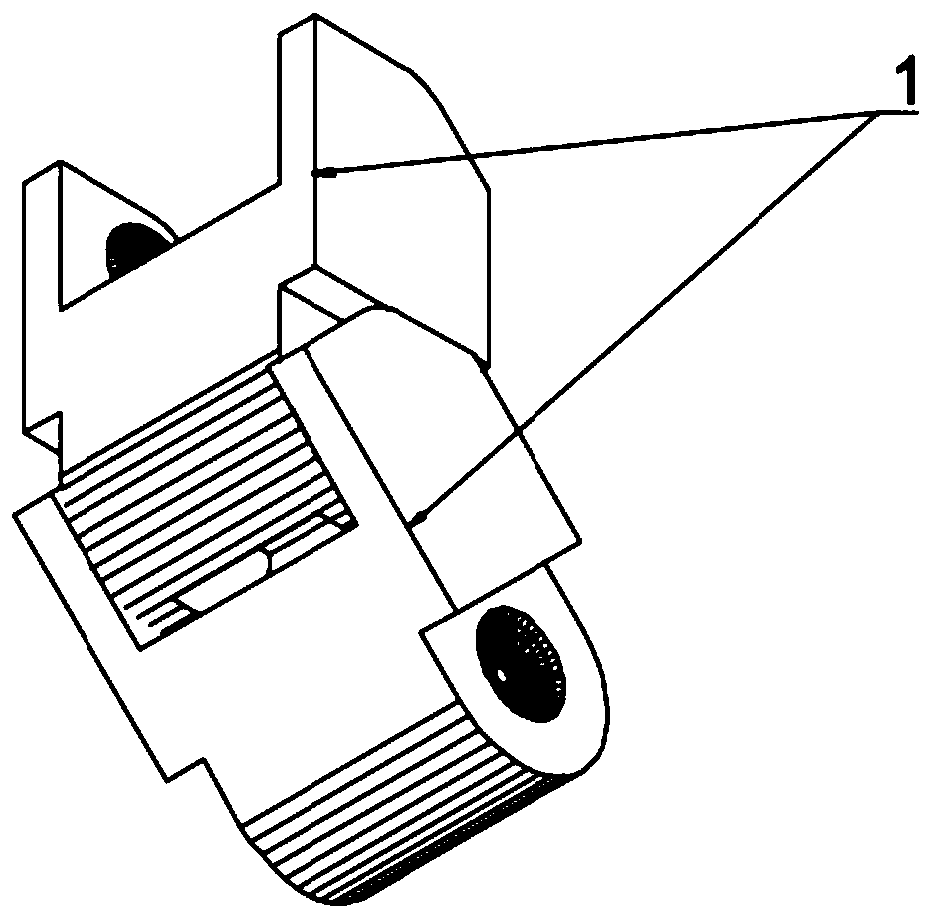

[0071] 1) For the monitoring of the 75mm outer radius oil-water gathering and transportation pipeline, the number of multiple sensor installation and protection units is selected to be 8, the angle between the limit gap 8 and the limit step 14 is 45°, and the limit gap 8 is close to the limit The distance L from one end of the position step 14 to the limit step 14 is 31.06 mm, and the multi-sensor installation and protection unit 1 with a total length of 77.3 mm, a height of 37.4 mm, and a width of 62.4 mm is processed out of aluminum alloy;

[0072] The first pipeline sensor installation slot on the unit is used to install temperature sensors, and the second pipeline sensor installation slot is used to install environmental sensors. A cylindrical slide rail is designed on the upper connecting ear of the multi-sensor installation and prot...

Embodiment 2

[0078] A multi-sensor embedding and protection method for gathering and transportation pipeline monitoring, comprising the following steps:

[0079] 1) For the monitoring of the 41.7mm outer radius oil-water gathering and transportation pipeline, the number of multi-sensor installation and protection units is selected to be 8, the angle between the limit gap 8 and the limit step 14 is 45°, and the limit gap 8 is close to The distance from one end of the limit step 14 to the limit step 14 is 17.27 mm, and the multi-sensor installation and protection unit 1 with a total length of 42 mm, a height of 20.7 mm, and a width of 34.6 mm is processed by ABS resin material;

[0080]The first pipeline sensor installation slot on the unit is used to install the deformation sensor, and the second pipeline sensor installation slot is used to install the attitude sensor. The upper end connection ear of the multi-sensor installation and protection unit 1 is designed with a cylindrical slide rai...

Embodiment 3

[0086] A multi-sensor embedding and protection method for gathering and transportation pipeline monitoring, comprising the following steps:

[0087] 1) For the monitoring of the 114mm outer radius oil-water gathering and transportation pipeline, the number of multi-sensor installation and protection units is selected to be 16, the angle between the limit gap 8 and the limit step 14 is 22.5°, and the limit gap 8 is close to the limit The distance from one end of the position step 14 to the limit step 14 is 22.68mm, and the multi-element sensor installation and protection unit 1 with a total length of 42mm, a height of 20.7mm, and a width of 34.6mm is processed out of polypropylene material;

[0088] The first pipeline sensor installation slot on the unit is used to install the acoustic wave sensor, the second pipeline sensor installation slot is used to install the leakage sensor, and a similar cylindrical slide rail is designed on the upper connecting ear of the multi-sensor in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com