A Flexible Extended Nozzle with Adaptive Height

An extension nozzle, self-adaptive technology, applied in the directions of jet propulsion, machine/engine, rocket engine, etc., can solve the problem of low rocket work efficiency, maximize the height compensation effect, continuous inner surface, and eliminate side effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings:

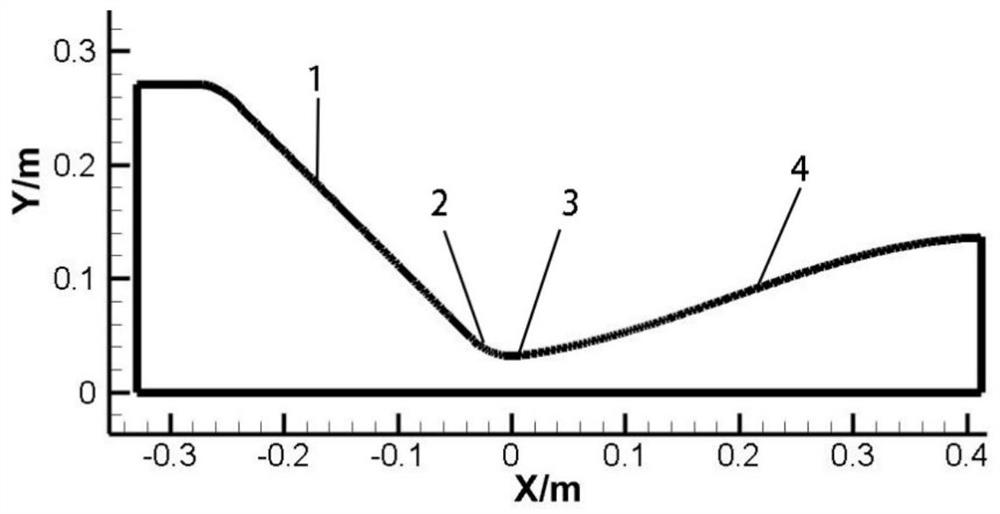

[0031] The technical solution of the present invention is achieved in this way: a flexible extension nozzle with self-adaptive height comprises a fixed section, a flexible extension section, a variable constraint point and a deployment device. The nozzle is designed as a multi-bell shape, and can Expand the extension according to the flight altitude. After the nozzle is deployed, the internal surface is multi-bell-shaped, and the characteristic line of each extension section adopts a polynomial curve or a B-spline curve, etc., and is in a fully expanded state at the outlet of each section. The flexible extension nozzle can be expanded in multiple stages, and the expansion ratio of the nozzle can be increased from a dozen to several hundreds. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com