Construction method of embedded FRP rib-reinforced roadway roof

A technology of roadway roof and construction method, which is applied to roof beams supporting mine roofs, earth-moving drilling, mining equipment, etc. Effectively contact the roadway roof and other problems to achieve excellent tensile mechanical properties, reduce the risk of shear failure, and avoid the effects of poor fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

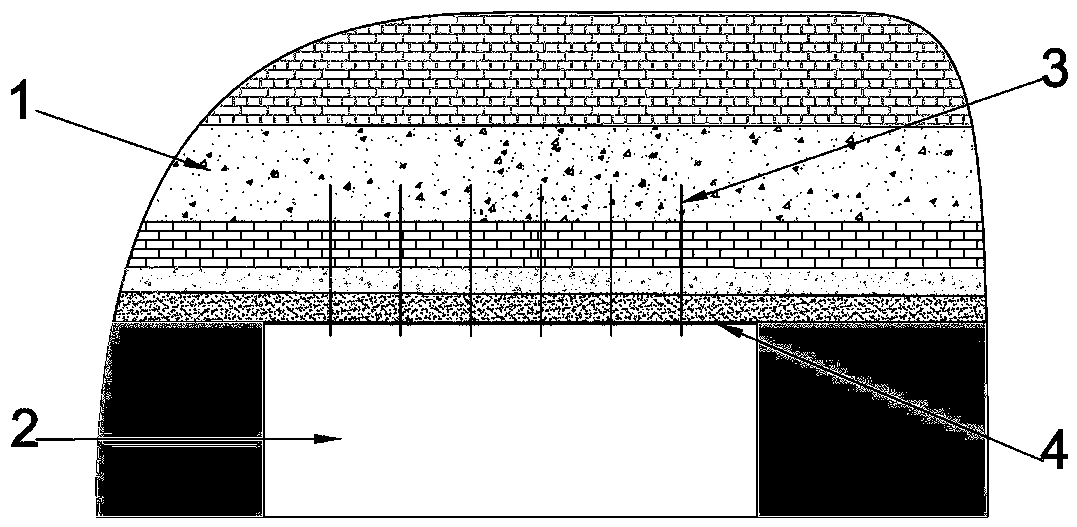

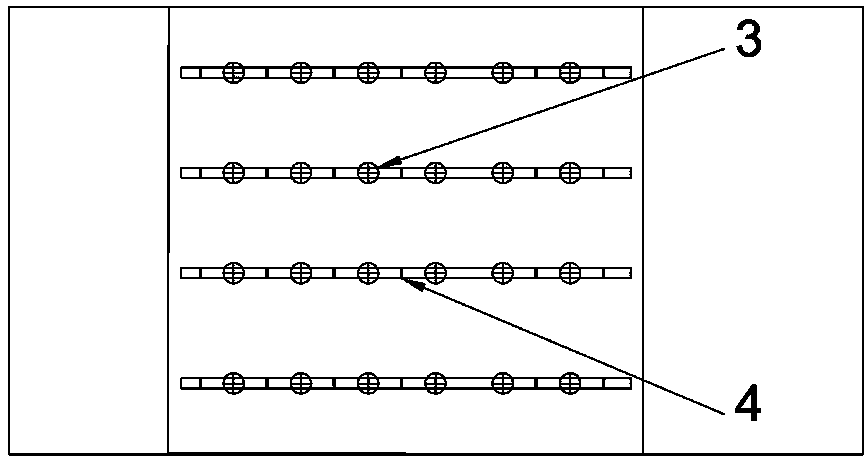

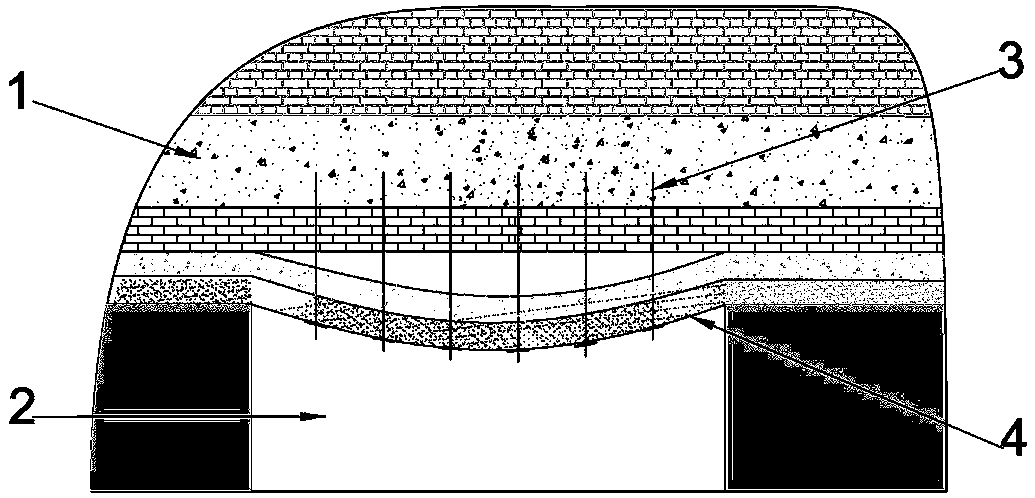

[0042] Below in conjunction with the accompanying drawings, the embodiment of the construction method of the embedded FRP bar reinforcement roadway roof of the present invention will be further described:

[0043] Such as Figure 1-3 As shown, after the excavation of the roadway 2 is completed, the roof 1 is reinforced with the anchor rod 3 . In order to further exert the supporting effect of the anchor rod 3 on the roof 1 of the roadway 2, a reinforced joist 4 is usually installed near the roof 1 at the tail of the anchor rod 3 . After the tunnel 2 is excavated, the original stress state is destroyed. Under the influence of mining, the roof 1 of the tunnel 2 will bend and sink, and the anchor rod 3 and the steel joist 4 will also appear in the process. The state of bending and sinking.

[0044] Such as Figure 4-5 Shown, the construction method that the embedded FRP reinforcement provided by the invention strengthens roadway roof comprises the following steps:

[0045] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com