High-pressure water jet and mechanical coupling integrated rock-breaking disc-type hobbing cutter and rock-breaking method

A high-pressure water jet, integrated technology, applied in the field of shield tunneling machines, can solve the problem of low tool coordination, and achieve the effects of improving rock breaking efficiency, improving tunneling efficiency, and simplifying installation design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

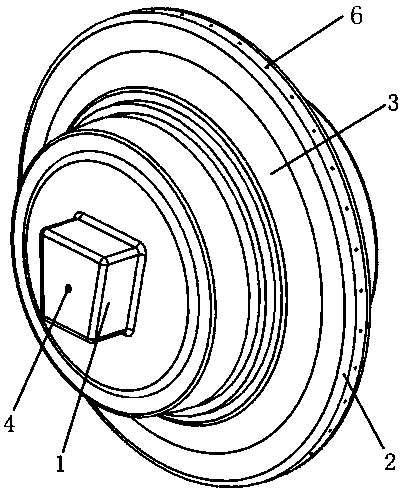

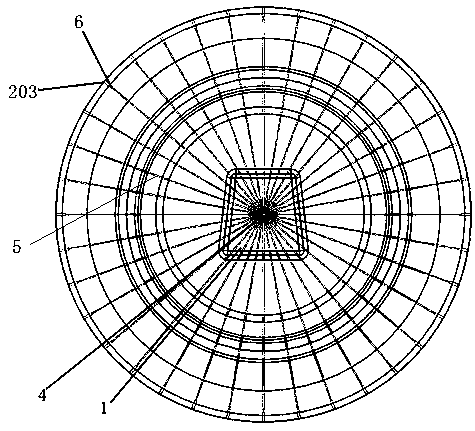

[0025] Example 1, such as Figure 1~3 As shown, a high-pressure water jet-mechanical coupling integrated rock-breaking hob includes a cutter shaft 1, a cutter body 3 and a cutter ring 2. The cutter body 3 is mounted on the cutter shaft 1 in rotation, and the cutter ring 2 is fixed on the On the knife body 3. The cutter shaft 1 is provided with a high-pressure water inlet channel 4, the cutter body 3 is provided with a high-pressure water distribution channel 5, and the cutter ring 2 is provided with a high-pressure water outlet channel 6, and the high-pressure water distribution channel 5 corresponds to the high-pressure water inlet channel 4 , the high-pressure water outlet channel 6 corresponds to the high-pressure water distribution channel 5 . The cutter ring 2 and the cutter housing 304 can rotate around the cutter shaft 1, so that the high-pressure water always works on the front side of the hob along with the rolling of the hob. When in use, high-pressure water enters...

Embodiment 2

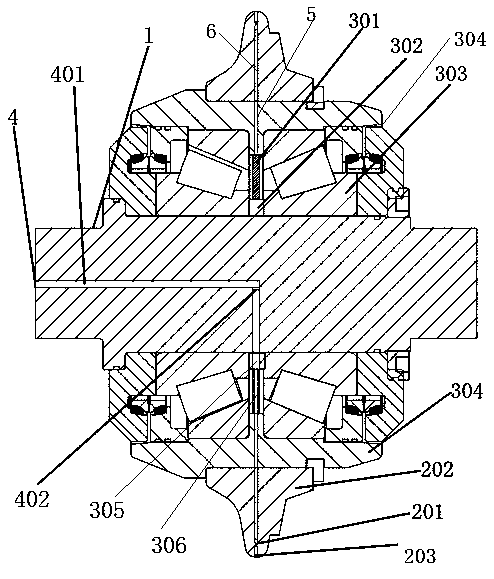

[0027] Example 2, such as figure 2 As shown, a high-pressure water jet-mechanical coupling integrated rock-breaking hob, the cutter body 3 includes a cutter housing 304, and the cutter housing 304 is installed on the cutter shaft 1 through two symmetrically arranged bearings 303, The knife housing 304 includes a top main housing and two side housings which seal the two bearings. An axial retaining ring 302 is arranged between two symmetrically arranged bearings 303, and the axial retaining ring 302 is sleeved on the cutter shaft. Set relatively static to the axial retaining ring 302 , or relatively stationary to the knife housing 304 , the seal 301 is used to seal the bearing and facilitate the passage of high-pressure water. The high-pressure water distribution channel 5 is arranged radially inside the knife housing 304 . In order to facilitate the directional passage of high-pressure water, the axial retaining ring 302 is provided with several first radial through holes 3...

Embodiment 3

[0030] Embodiment 3: A rock-breaking method of a high-pressure water jet-mechanical coupling integrated rock-breaking disc hob, comprising the following steps:

[0031]S1: The high-pressure water outlet channel 6 on the cutter shaft 1 is connected to the high-pressure water system of the roadheader;

[0032] S2: When the high-pressure water jet is used to break the rock during the tunneling process of the roadheader, the high-pressure water of the high-pressure water system enters the hob through the high-pressure water inlet channel 4, and then sprays out through the high-pressure water distribution channel 5 and the high-pressure water outlet channel 6 to form high-pressure water. The jet impacts on the rock surface, causing cracks on the rock surface, and then the rock surface is crushed by the hob to achieve rock breaking, such as Figure 5 shown.

[0033] In step S2, during the rolling process of the hob, the cutter housing of the hob rotates passively, and the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com