Concrete formwork combining and flatness adjusting structure

A technology for concrete formwork and adjustment structure, which is applied in the connection parts of formwork/formwork/work frame, building structure, and on-site preparation of building components, etc. It is difficult to control the flatness and other problems to achieve stable positioning, ensure flatness, and prevent the reduction of concrete quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings. In the following description, the side where the concrete is poured is the inner or front side of the formwork, and the opposite side is the back side.

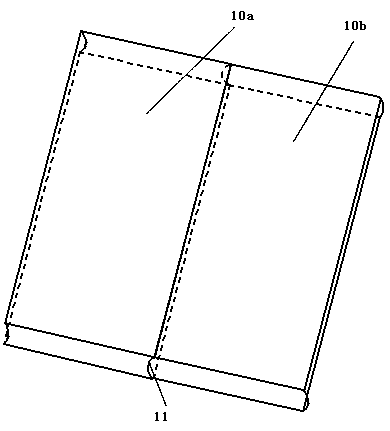

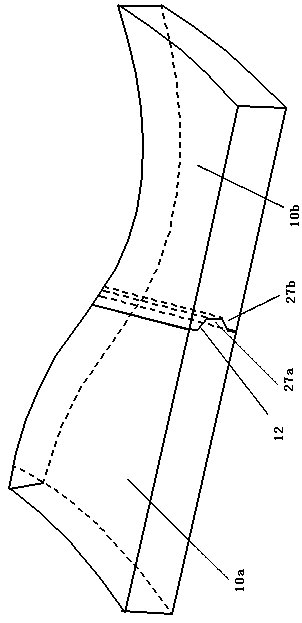

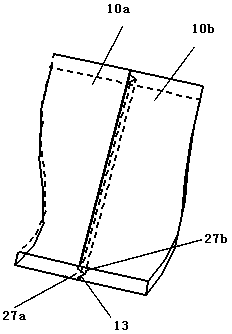

[0030] The technical solution of the present invention is: a concrete formwork combination and a flatness adjustment structure, figure 1 It is a schematic diagram of the side structure of the template end structure Figure 1 , figure 2 It is a schematic diagram of the cross-sectional structure of the butt joint at the end of the formwork Figure II , image 3 It is a schematic diagram of the cross-sectional structure of the butt joint at the end of the formwork Figure three. Formwork 10 comprises steel formwork, wood formwork, steel formwork and wooden formwork hybrid form, and the back side of described formwork 10 is provided with fixing mechanism, is provided with many pairs of adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com