Automatic cleaning device of carding machine

A technology of cleaning device and carding machine, which is used in deburring device, fiber processing, textile and papermaking, etc., can solve the problems of cotton flock floating, can not effectively avoid cotton jam in the carding machine, and can not deal with dust, so as to avoid Card cotton effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

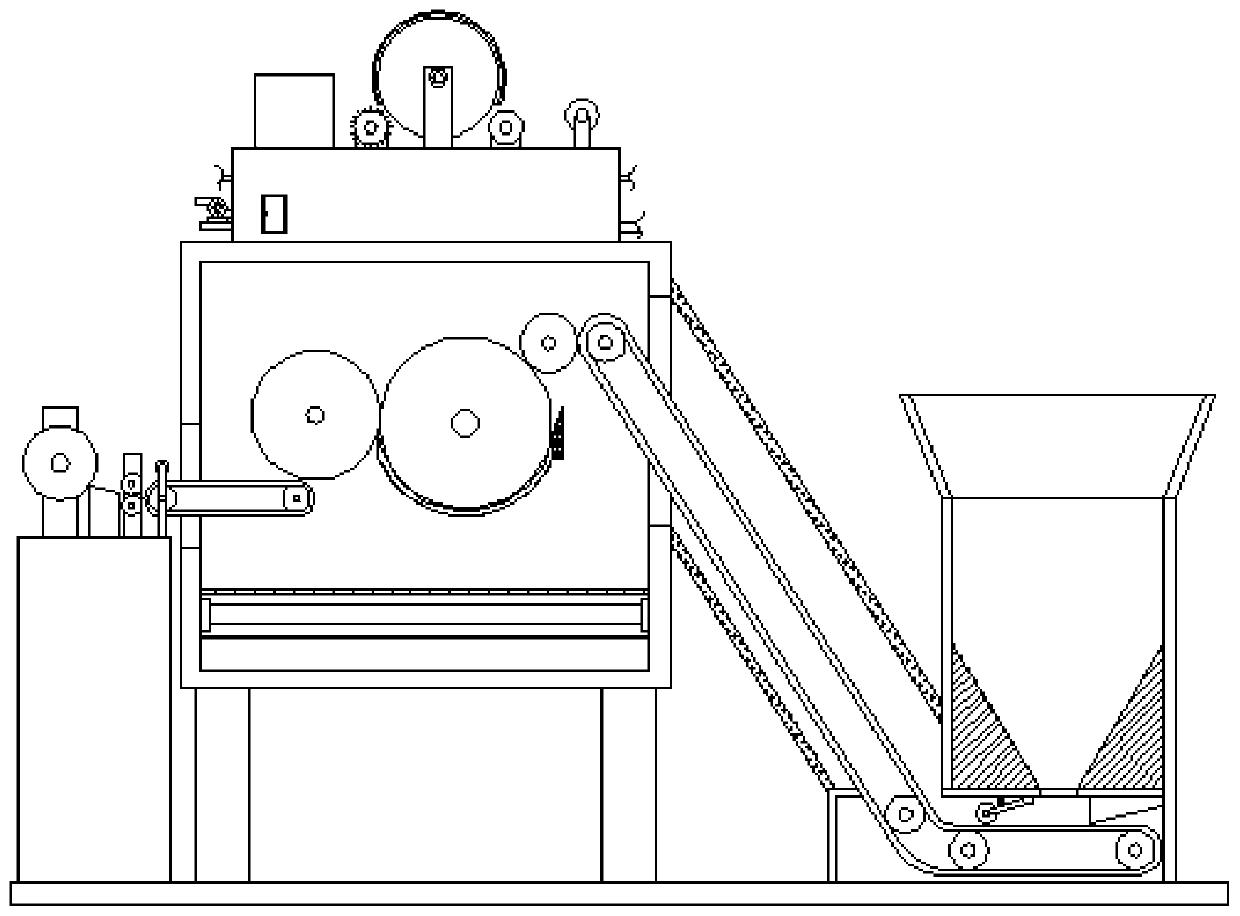

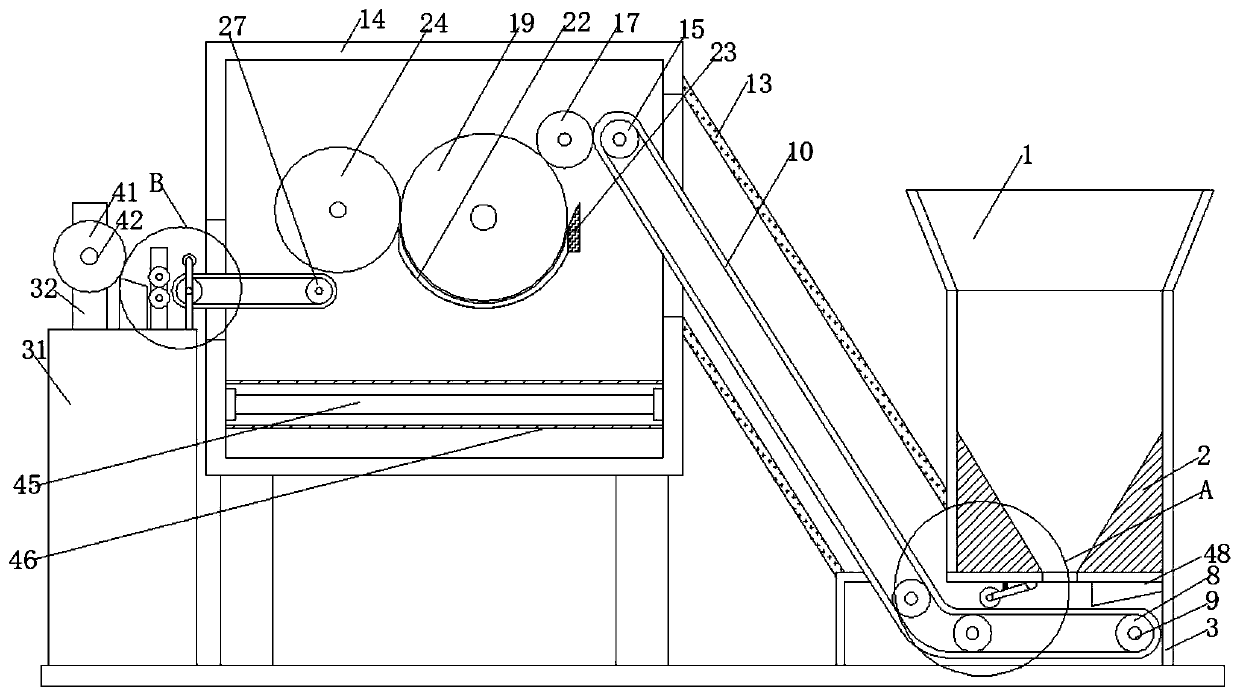

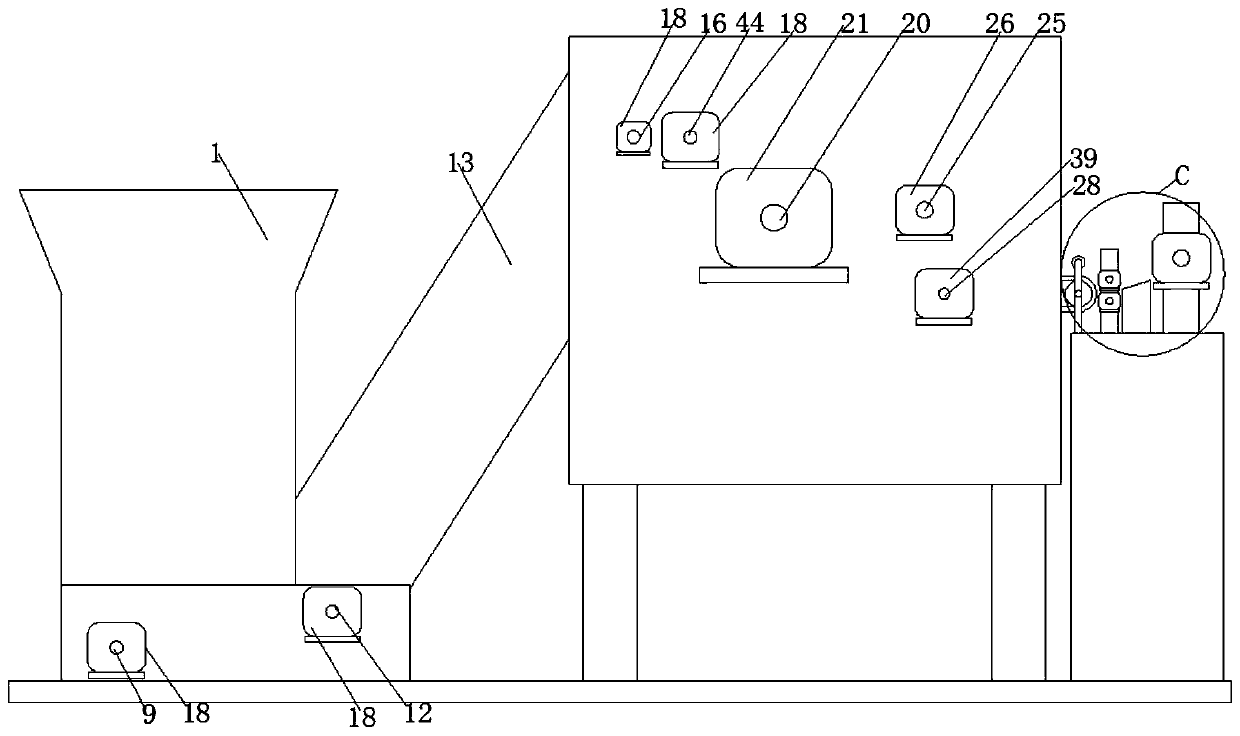

[0036] see Figure 1-10 , an automatic cleaning device for a carding machine, which includes a carding machine body, an anti-jamming mechanism and a dust removal mechanism.

[0037] Among them, the anti-jamming mechanism is arranged in the carding machine, which includes a funnel 1, the inner lower side of the funnel 1 is fixedly connected with a material guide block 2, the bottom of the funnel 1 is fixedly connected with a material guide box 3, and the inner top wall of the material guide box 3 The hinged ball 4 is fixedly connected, the bottom of the hinged ball 4 is fixedly connected with the hinged rod 5, the top of the guide box 3 is fixedly connected with an elastic spring 6, and the bottom of the elastic spring 6 is fixedly connected with the top left side of the hinged rod 5, and the hinged rod The bottom end of 5 is rotatably connected with the first flat roller 7, the front and rear walls on the left side inside the guide box 3 are rotatably connected with a No. 1 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com