Acidification roasting device for increasing conversion rate of lithium carbonate and production method of acidification roasting device

A technology of acidification roasting and conversion rate, which is applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of affecting the progress of materials, affecting production, cleaning difficulties, etc., and achieve the effect of improving conversion rate and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

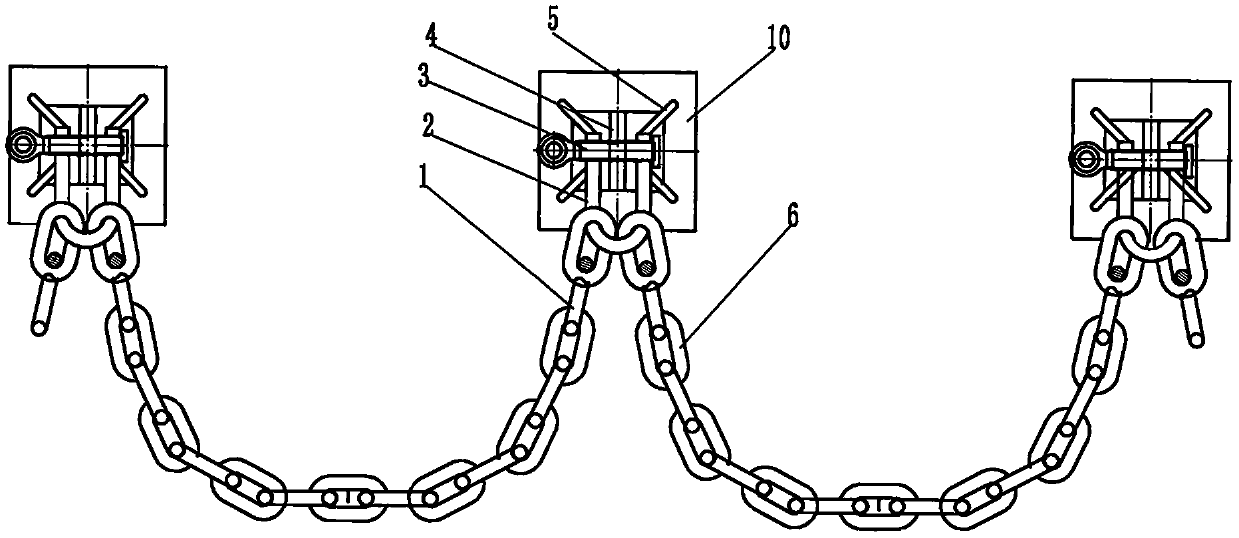

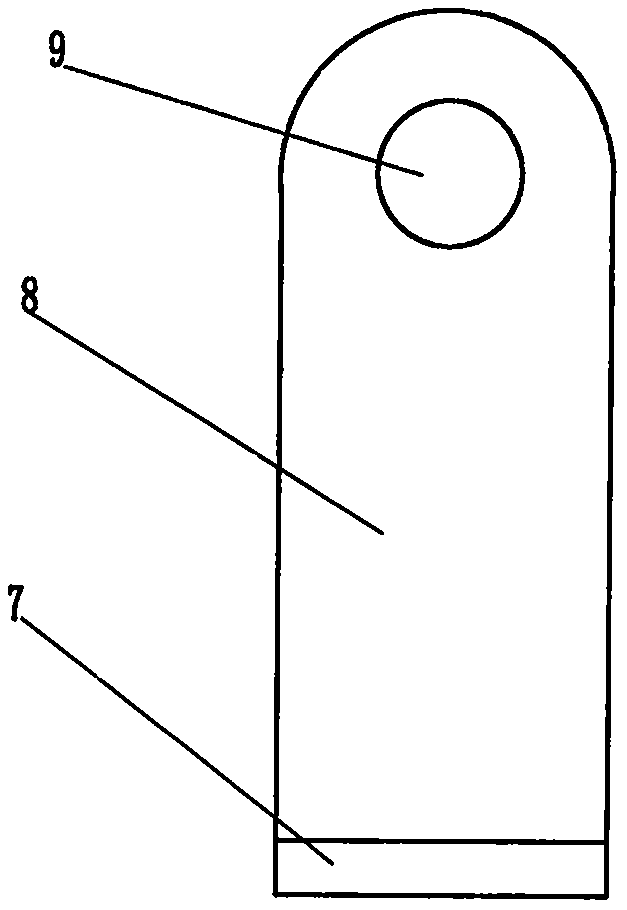

[0017] In the accompanying drawings, a kind of acidification roasting device of the present invention improves lithium carbonate conversion rate, comprises fixed plate, reinforcing rib, connecting pin, connecting buckle and iron chain; Described fixed plate 4 is made of base 7 and vertical plate 8, The vertical plate 8 is vertically welded on the base 7, and the vertical plate 8 is semicircular away from the end of the base and is provided with a pin hole 9; The base is fit and welded on the fixed plate 4, and the tail end exceeds a part of the base; the tail end of the reinforcing rib 5 exceeds the base part and is welded and connected with the roasting rotary kiln cylinder 10, the purpose is to connect the fixed plate with the rotary kiln after pouring stronger. The iron chain 1 is connected by a plurality of hoops 6, and its tail end is hung on the connecting buckle 2, and the connecting buckle 2 is movably connected on the fixed plate 4 by the connecting pin 3.

[0018] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com