Low-heat-conduction and high-toughness aluminum-manganese-cobalt-series die-cast aluminum alloy and processing technology thereof

An aluminum-manganese-cobalt-based, cast aluminum alloy technology, applied in the field of alloys, can solve the problems of increasing the production cost of aluminum alloys, the high cost of graphene microchips, and reducing aluminum alloys, so as to improve production efficiency, reduce pinholes, and improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

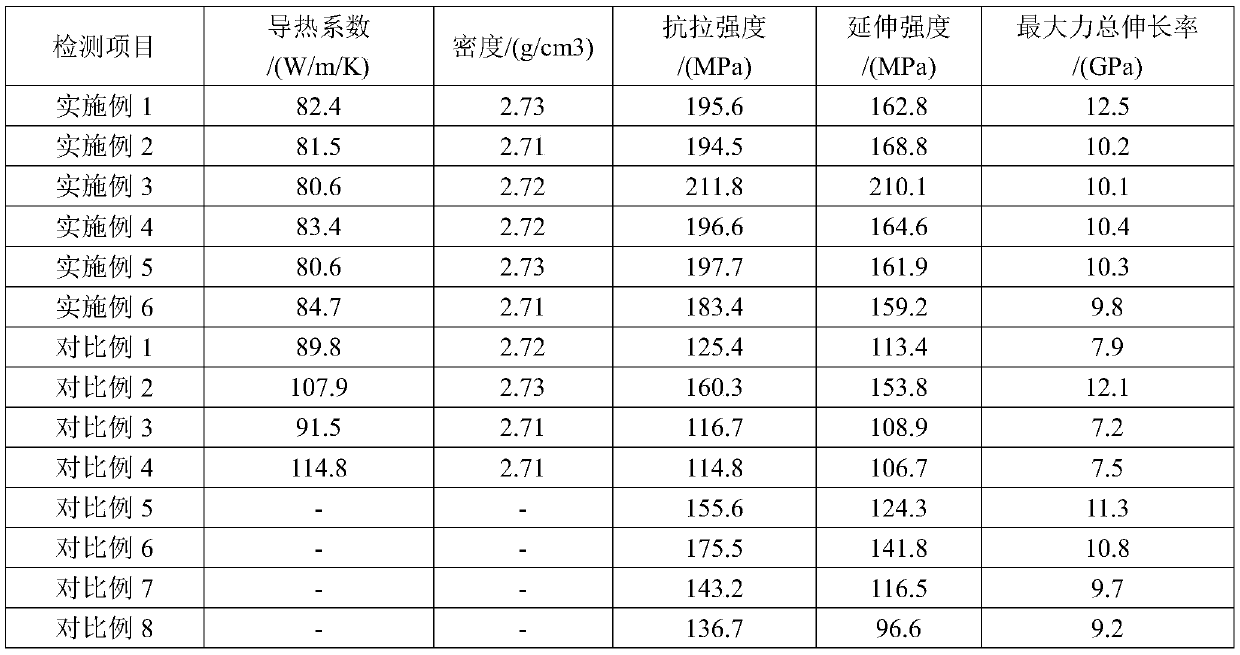

Examples

Embodiment 1

[0043] An Al-Mn-Co-based die-casting aluminum alloy with low thermal conductivity and high toughness

[0044] By weight percentage, it consists of the following components, including Mn: 1%, Co: 0.1%, Mg: 9%, Cr: 0.3%, Ni: 0.17%, Si: 2.3%, trace elements: 0.4%, impurity elements ≤ 0.5%, the balance is Al.

[0045] Adopt following method to process: comprise the following steps:

[0046] A. Prepare AlMn10, AlCo10, AlSi20, AlCr5, AlNi10, Mg ingots, Al ingots, and AlB3 master alloys for later use;

[0047] B. Heat the Al ingot, when it is heated to 780°C, add AlCr5, AlCo10, keep it warm for 30 minutes, stir and remove slag;

[0048] C. When the temperature is lowered to 760°C, add AlSi20, AlMn10, AlNi10, and AlB3 master alloys, keep the temperature for 30 minutes, and stir to remove slag;

[0049] D. When the temperature is lowered to 700°C, add Mg ingots, keep the temperature for 20 minutes, stir and remove slag, and form aluminum liquid;

[0050] E. Then, under the action o...

Embodiment 2

[0054] An Al-Mn-Co-based die-casting aluminum alloy with low thermal conductivity and high toughness

[0055] By weight percentage, it consists of the following components, including Mn: 1.4%, Co: 0.7%, Mg: 8.5%, Cr: 0.25%, Ni: 0.1%, Si: 1.5%, trace elements: 0.1%, impurity elements ≤ 0.5%, the balance is Al.

[0056] Adopt following method to process: comprise the following steps:

[0057] A. Prepare AlMn10, AlCo10, AlSi20, AlCr5, AlNi10, Mg ingots, Al ingots, and AlRe10 master alloys for later use;

[0058] B. Heat the Al ingot, when it is heated to 780°C, add AlCr5, AlCo10, keep it warm for 30 minutes, stir and remove slag;

[0059] C. When the temperature is lowered to 740°C, add AlSi20, AlMn10, AlNi10, AlRe10 master alloys, keep warm for 30 minutes, stir and remove slag;

[0060] D. When the temperature is lowered to 690°C, add Mg ingot, keep it warm for 20 minutes, stir and remove slag, and form aluminum liquid;

[0061] E. Then, under the action of the all-in-one ma...

Embodiment 3

[0064] An Al-Mn-Co-based die-casting aluminum alloy with low thermal conductivity and high toughness

[0065] By weight percentage, it consists of the following components, including Mn: 1.3%, Co: 0.5%, Mg: 8%, Cr: 0.2%, Ni: 0.15%, Si: 2.1%, trace elements: 0.3%, impurity elements ≤ 0.5%, the balance is Al.

[0066] Adopt following method to process: comprise the following steps:

[0067] A. Prepare AlMn10, AlCo10, AlSi20, AlCr5, AlNi10, Mg ingots, Al ingots, and AlTi5B1 master alloys for later use;

[0068] B. Heat the Al ingot, when it is heated to 780°C, add AlCr5, AlCo10, keep it warm for 30 minutes, stir and remove slag;

[0069] C. When the temperature is lowered to 740°C, add AlSi20, AlMn10, AlNi10, AlTi5B1 master alloys, keep warm for 30 minutes, stir and remove slag;

[0070] D. When the temperature is lowered to 700°C, add Mg ingots, keep the temperature for 20 minutes, stir and remove slag, and form aluminum liquid;

[0071] E. Then, under the action of the all-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com