Transportation system and method for blast furnace shell

A blast furnace shell and transportation system technology, which is applied in the field of blast furnace overhaul, can solve the problems of low safety, high construction cost, low stability, etc., and achieves the effects of saving the use of benches, low installation cost, and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

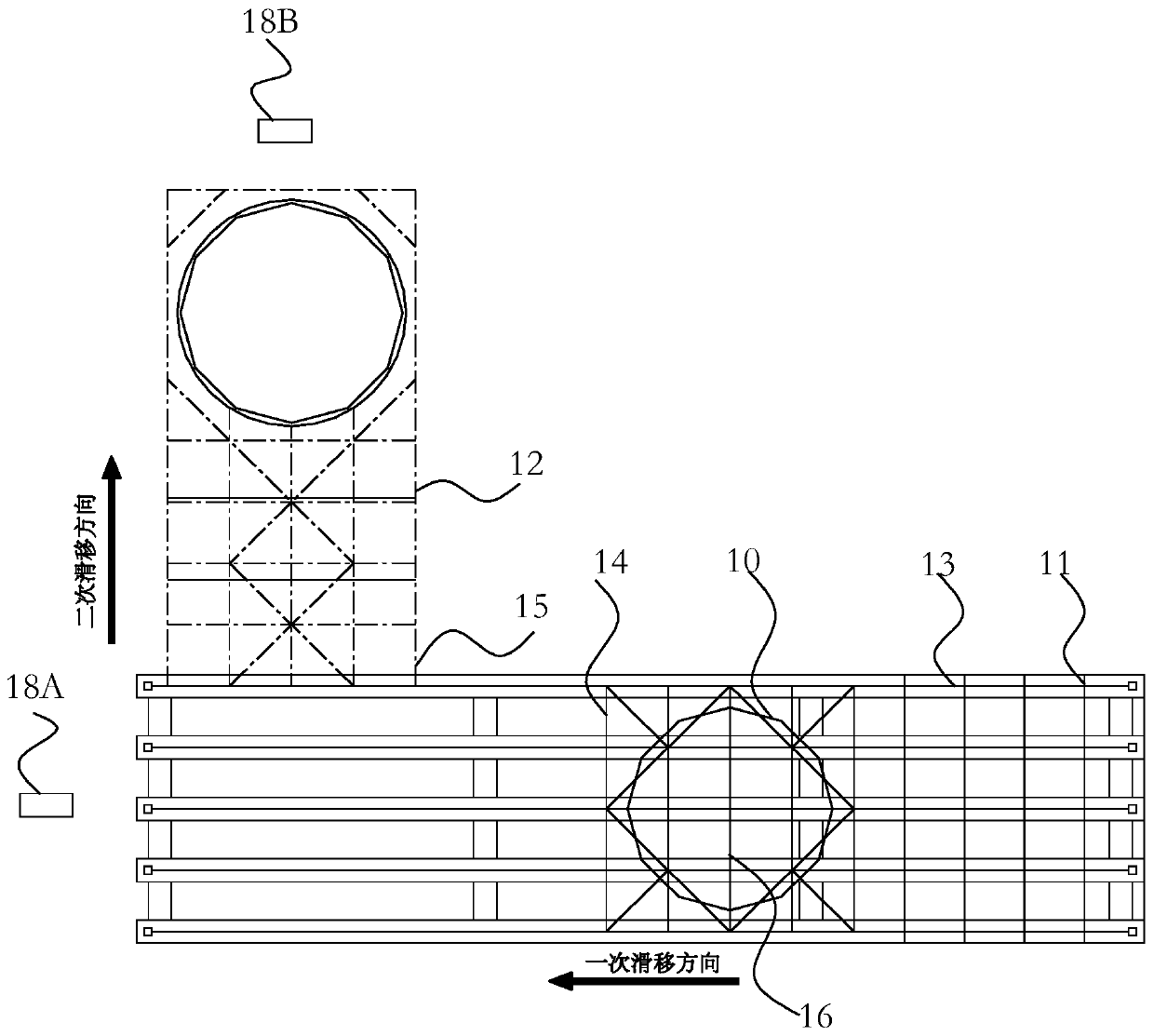

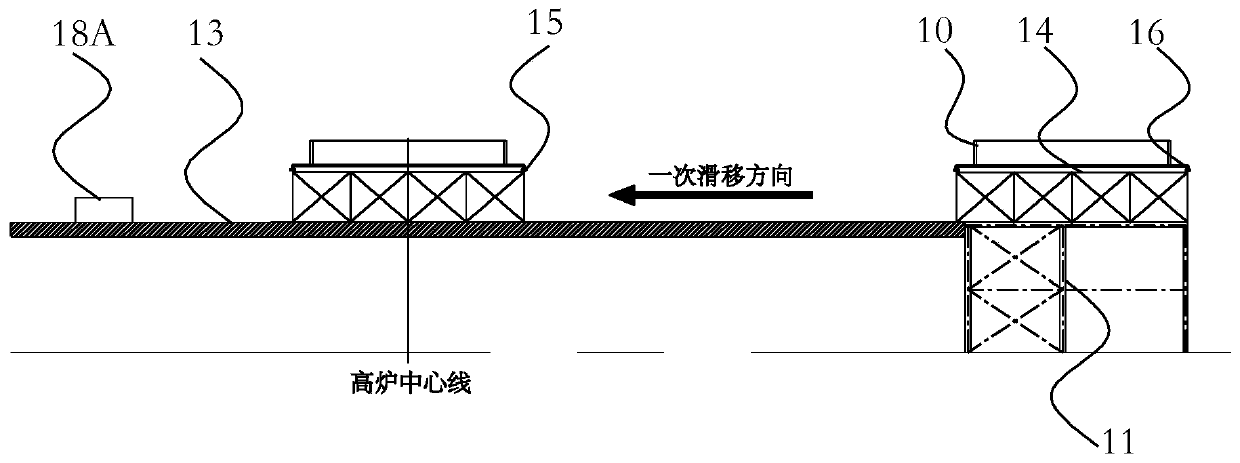

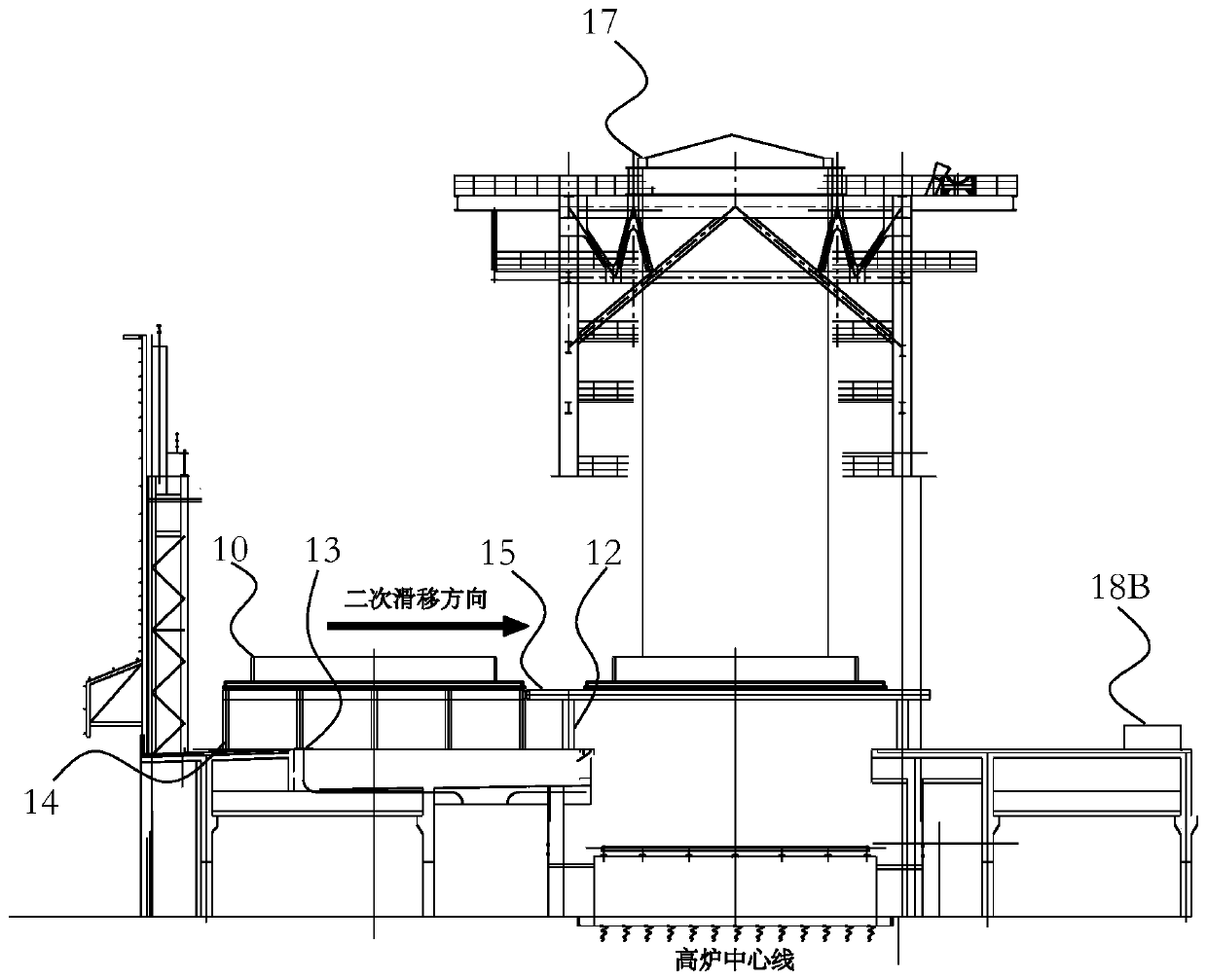

[0023] Such as figure 1 and figure 2 as well as image 3 As shown, this embodiment provides a transportation system for blast furnace shells, including a material receiving platform 11 arranged outside the casthouse and a frame 12 around the furnace body arranged around the center of the casthouse furnace frame, wherein A sliding track 13 is provided on the material receiving platform 11 and the casthouse platform, a sliding truss 14 is arranged on the primary sliding track 13, and a frame 12 around the sliding truss 14 and the furnace body The upper part is provided with a secondary sliding track 15, and the extending direction of the primary sliding track 13 intersects with the extending direction of the secondary sliding track 15, and the sliding truss 14 is provided with a sliding car 16, The skid truck 16 transports the furnace shell 10 from the material receiving platform 11 to an installation position on the secondary skid track 15 via the primary skid track 13 .

...

Embodiment 2

[0029] Such as figure 1 and figure 2 as well as image 3 As shown, this embodiment provides a method for transporting a blast furnace shell, using the blast furnace shell transport system described in Embodiment 1 to transport the furnace shell 10, including the following steps: Step S1: Put the assembled furnace shell 10 Hoisting to the skid car 16 on the skid truss 14 on the material receiving platform 11; step S2: pulling the skid truss 14, sliding the furnace shell 10 to the interface position of the frame 12 around the furnace body, and completing once Sliding; step S3: pulling the skid car 16, sliding the furnace shell from the interface position of the frame 12 around the furnace body to the center of the furnace body frame, transporting it to the installation position, and completing the secondary sliding; step S4: waiting After the furnace shell 10 is lifted and fixed, the trolley 16 is pulled back to the sliding truss 14 at the interface position of the frame 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com