Artificial microcrystalline pumice material and method for preparing artificial microcrystalline pumice material from industrial solid waste by volcanic diagenesis method at low temperature

A technology of industrial solid waste and artificial micro-pumice, applied in the field of artificial micro-crystalline pumice materials and low-temperature preparation of artificial micro-crystalline pumice materials from industrial solid waste by volcanic diagenesis, which can solve the problems of low water absorption, low thermal conductivity, supply shortage, etc., and achieve water absorption. Low-cost, versatile, and high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

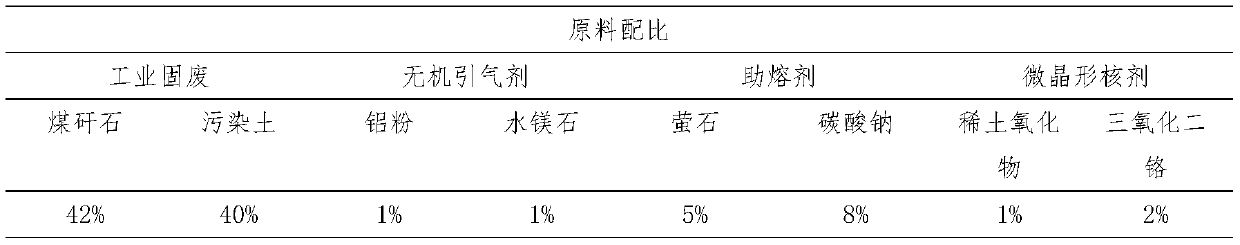

[0025] The raw material ratio (percentage by weight, the same below) of the artificial microcrystalline pumice material is as shown in table 1:

[0026] The raw material ratio of table 1 artificial microcrystalline pumice material

[0027]

[0028] Among the above raw materials, the weight ratio of the components is: Al 2 o 3 : SiO 2 : CaO: MgO: Fe 2 o 3 :K 2 O: Na 2 O=5:70:4:4:9:3:1.

[0029] The artificial microcrystalline pumice material is prepared according to the following steps:

[0030] 1. Select the raw materials shown in Table 1.

[0031] 2. The raw materials selected in step 1 were weighed according to the proportion shown in Table 1, mixed, and ground in a ball mill with a fineness of 30 microns to obtain raw meal powder.

[0032] 3. Stamping the raw meal powder prepared in step 2.

[0033] 4. Sinter the shaped raw meal prepared in step 3 in a tunnel kiln, set the maximum firing temperature to 900°C, and the heating rate to 10°C / min.

[0034] 5. The m...

Embodiment 2

[0037] The ratio of raw materials of artificial microcrystalline pumice material is as shown in table 2:

[0038] The raw material ratio of table 2 artificial microcrystalline pumice material

[0039]

[0040] Among the above raw materials, the weight ratio of the components is: Al 2 o 3 : SiO 2 : CaO: MgO: Fe 2 o 3 :K 2 O: Na 2 O=10:72:3:3:4:1:2.

[0041] The artificial microcrystalline pumice material is prepared according to the following steps:

[0042] 1. Select the raw materials shown in Table 2.

[0043] 2. The raw materials selected in step 1 are weighed according to the proportion shown in Table 2, mixed, and ground in a ball mill to control the particle size to about 25 microns to obtain raw meal powder.

[0044] 3. Extrude the raw meal powder prepared in step 2.

[0045] 4. The shaped raw meal prepared in step 3 is sintered in a roller kiln, the maximum firing temperature is set at 850°C, and the heating rate is 15°C / min.

[0046] 5. The material obtai...

Embodiment 3

[0049] The raw material ratio of artificial microcrystalline pumice material is as shown in table 3:

[0050] The raw material ratio of table 3 artificial microcrystalline pumice material 1

[0051]

[0052]

[0053] Among the above raw materials, the weight ratio of the components is: Al 2 o 3 : SiO 2 : CaO: MgO: Fe 2 o 3 :K 2 O: Na 2 O=10:65:5:3:6:1:2.

[0054] The artificial microcrystalline pumice material is prepared according to the following steps:

[0055]1. Select the raw materials shown in Table 3.

[0056] 2. The raw materials selected in step 1 are weighed according to the proportion shown in Table 3, mixed, and ground in a ball mill to control the particle size to about 35 microns to obtain raw meal powder.

[0057] 3. Extrude the raw meal powder prepared in step 2.

[0058] 4. Put the molding raw material prepared in step 3 in 1m 3 Sintering in a shuttle kiln with a maximum firing temperature of 980°C and a heating rate of 12°C / min.

[0059] 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com