Fully-automatic debugging equipment for performance of electronic control valve

An electric control valve, fully automatic technology, applied in the direction of electrical program control, circuit breaker testing, sequence/logic controller program control, etc., to improve production efficiency, ensure debugging accuracy, and improve the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

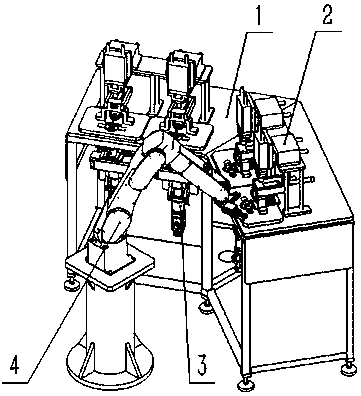

[0025] like figure 1 As shown, a fully automatic debugging device for the performance of an electric control valve, its structure includes a frame 1, a pressing and positioning assembly 2, a debugging assembly 3 and a robot loading and unloading assembly 4, in which 4 sets of pressing and positioning assemblies 2 are placed on the frame 1 Above, a set of debugging components 3 is provided below each set of pressing components 2 , and a robot loading and unloading component 4 is arranged on the periphery of the frame 1 .

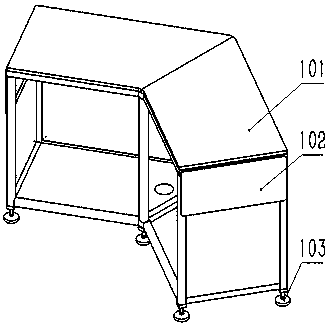

[0026] like figure 2 As shown, the frame 1 is spliced by two trapezoidal prismatic frame structures in cross section, and its structure includes a frame connecting plate 101, a frame reinforcing plate 102, and frame feet 103, wherein two frames are connected The plate 101 is arranged on the upper surface of the frame 1, two frame reinforcement plates 102 are arranged on the upper parts of the left and right sides of the frame 1, and the six frame feet 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com