Novel composite carbon steel floating plate and preparation method thereof

A composite carbon and floating disk technology, applied in large containers, containers, packaging, etc., can solve problems such as aggravated corrosion, inability to use anode protection for floating disks, and damage to anti-corrosion layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention at first provides a kind of preparation method of novel composite carbon steel floating plate, comprises the following steps:

[0056](1) Pretreatment before construction: Before construction, carry out derusting treatment on the carbon steel floating plate, and remove the floating rust on the bottom plate and side wall of the carbon steel floating plate; Brush a layer of special primer on the inner surface of the through-hole for construction, so that the surface of the bottom plate, the surface of the side wall, and the inner surface of the through-hole are all infiltrated with the special primer; The surface of the part is puttyed to make the surface of the bottom plate and side wall smooth;

[0057] (2) Through hole construction: The through holes on the carbon steel floating plate include manholes, guide column openings and floating plate outrigger openings. After the pretreatment in step (1) is completed, the through holes are constructed: fi...

Embodiment 1

[0070] In this example, the prepreg of the light-cured FRP material used is the CP201 prepreg sheet produced by Beijing Yingren Technology, with a thickness of 1.5mm and a width of 2 meters; it uses 470 light-curable resin and E glass fiber Chopped strand mat is the main raw material, which has high strength and corrosion resistance. In this embodiment, the interface glue is 470 photocurable resin, and the thickness of the coating is about 0.1mm.

[0071] A method for preparing a new type of composite carbon steel floating disc. A conventional carbon steel floating disc is manufactured in a floating roof oil tank according to the traditional method. After the carbon steel floating disc is manufactured, the immersion part of the carbon steel floating disc is subjected to photocuring The construction of FRP materials includes the following steps:

[0072] (1) Pretreatment before construction: Before construction, carry out derusting treatment on the carbon steel floating plat...

Embodiment 2

[0082] A novel composite carbon steel floating disc is prepared through the preparation method of Example 1:

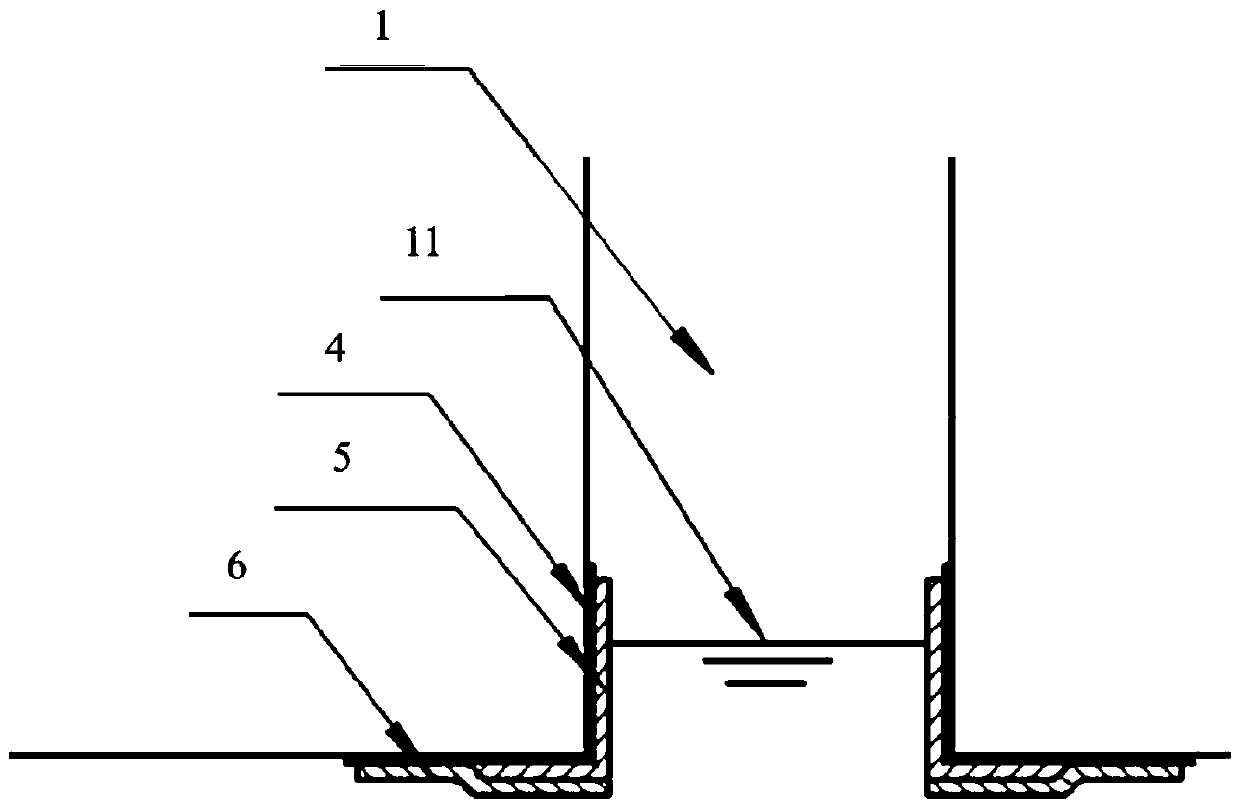

[0083] The main body of the floating plate, the inner wall of the through hole 1 is painted and / or laid in turn with a special primer layer A4 and a prepreg layer 5 of light-cured FRP material from the inside to the outside. An annular reinforcing ring 6 is pasted on the surface of the through hole, and the inner circle of the reinforcing ring is facing the inner diameter of the through hole; the special primer layer, the prepreg layer of light-cured FRP material and the reinforcing ring constitute the corrosion resistance of the through hole. layer;

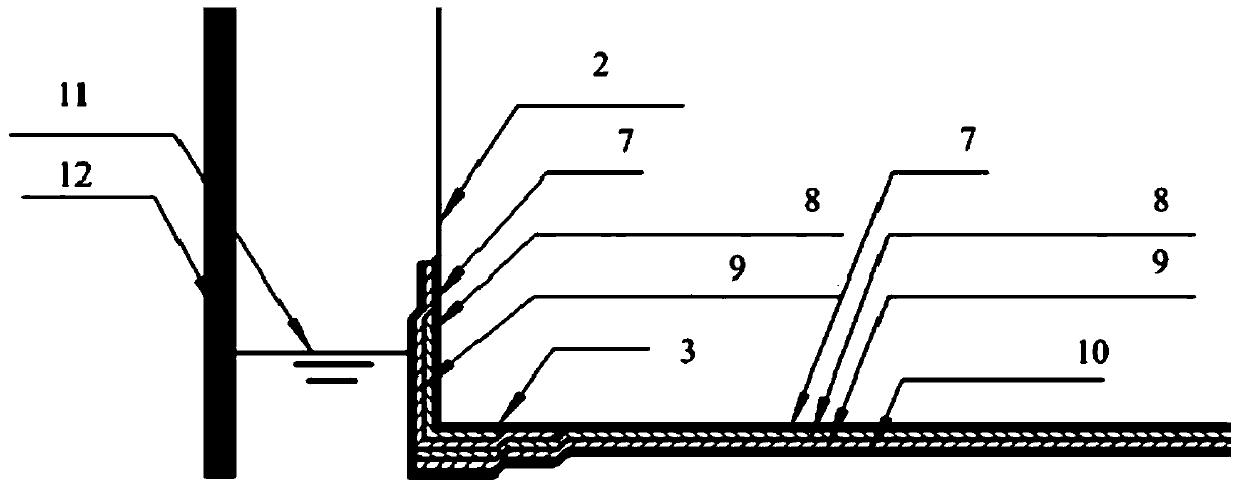

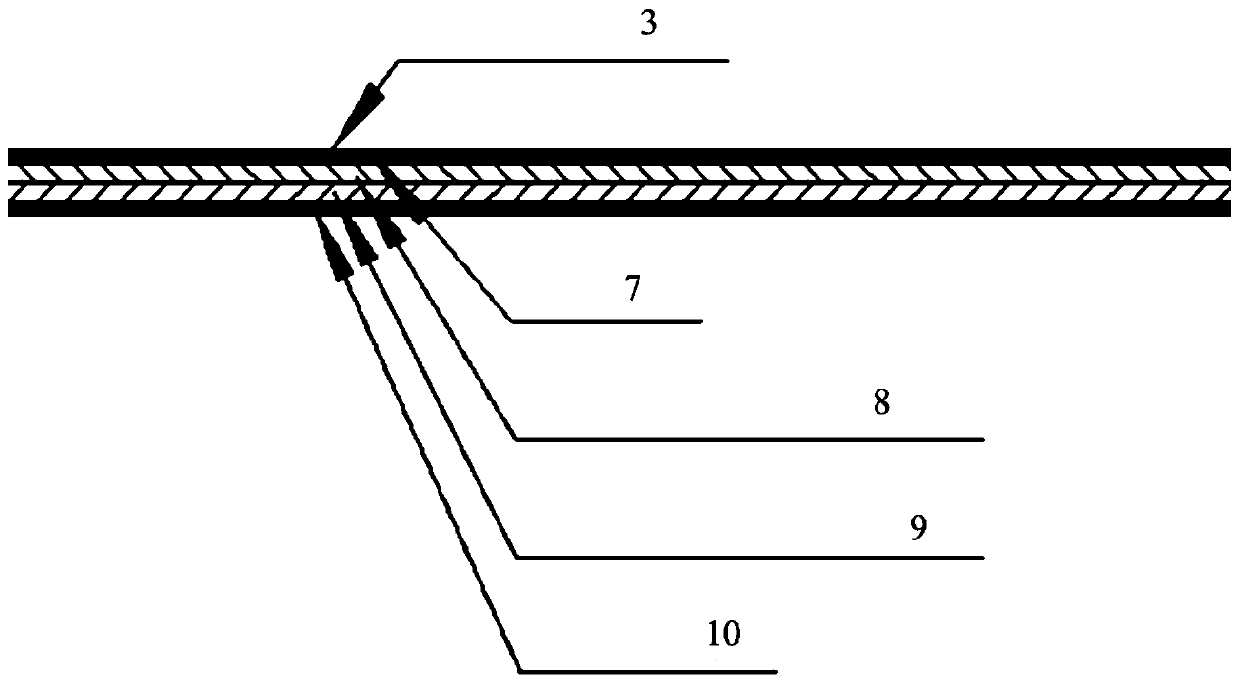

[0084] The main body of the floating tray, its side wall 2 and bottom plate 3 are painted and / or laid with a special primer layer B7, a first layer of prepreg layer 8 of light-cured FRP material, and a second layer of light-cured fiberglass material from the inside to the outside. The prepreg layer 9 and conductive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com